Concrete surfaces, including the floor, are preferred not to be painted, but left in their original form. However, even a material as strong as concrete is subject to mechanical damage, chips and chemical attack. Therefore, the procedure for painting a concrete floor is not just a work to improve the room, but a way to protect the coating. But it remains to be seen how to paint a concrete floor?

Concrete floor protection

Concrete floors are most often built up in industrial or commercial buildings. But along with this they can be seen in home workshops, garages, cellars, outbuildings and pantries. Although concrete itself is able to withstand heavy loads under adverse conditions of use, it still requires protection.

Concrete is characterized by high porosity and a low level of tensile strength; therefore, when external factors act on its unprotected surface, it wears out, peels off, after which characteristic dust arises. This occurs most often in cases of using low-quality concrete, violation of laying technology, improper mixing of the mixture, and the use of poor cement.

To protect the concrete surface, it is customary to use special compounds. In addition to the decorative properties, painting a concrete floor provides its protection against destruction, the influence of aggressive environments and abrasive wear, gives such additional properties as hygiene, anti-slip, decontamination, anti-static, smooths out irregularities, and masks various floor defects - chips, cracks, sinks and cavities.

The choice of paint for concrete

For painting concrete floors, alkyd and epoxy paints are usually used, which are distinguished by unique anti-slip and antistatic properties, as well as great resistance to chemicals. The epoxy substance must be prepared, mixed and tinted before use, the alkyd substance does not need to be prepared for use. But before working with alkyd paint, the concrete surface should be primed, epoxy paint does not require this.

In addition to paints, soil mixtures are widely used, which are designed to transform a very neglected floor. Tinting impregnations give concrete a vibrant color coating. Polymer compositions are able to hide all defects and smooth the surface, the use of special putty allows any concrete coating to be made monolithic. Glitter and flocking, which do not fade over time, will help provide additional decorativeness to the floor.

When choosing which paint is best for a concrete floor, it is recommended to take into account the characteristics of the room. For example, in industrial places where mechanical damage or shock types of surface loads are often possible, a high reliability coating is required. In this case, it is best to use wear-resistant paints.

For thin-layer bulk coatings for civilian purposes, a varnish for a concrete floor or polyurethane enamel is chosen. To finish the floor in garages and treat concrete elements of landscape design, we use tools that are designed to cover various industrial premises, which are based on solvents and epoxy enamels.

To paint the concrete floor in the living room, it is necessary to take a composition with a water base. For surface treatment on balconies and corridors, it is better to buy two-component polyurethane elastomers. If you need waterproof coating, give preference to single-component polyurethane dyes. Next, we consider the advantages of each type of paint composition for a concrete floor.

Epoxy paint

Epoxy paint is a very strong and durable coating that extends the useful life of the floor and guarantees a presentable appearance. Such paint is quite resistant to external influences and various chemical environments - acids, alkalis, fuels and lubricants, salt solutions, has waterproofing properties, can withstand heavy loads and perfectly adheres to concrete.

The epoxy does not wear out and does not turn yellow, even if you cover the concrete floor in hangars, production shops, car repair shops and parking lots. You can use this paint in open areas, as it is resistant to atmospheric phenomena, and indoors. Another advantage of this paint is the possibility of applying it directly to fresh, not sufficiently dried concrete.

The main drawback of epoxy paint for concrete flooring is its two-component nature: before use, it must be mixed. Some problems may occur with repeated staining. In addition, if you want to change the color of the concrete floor to another, it will be quite difficult to do.

Acrylic paint

Acrylic paint for concrete surfaces is an aqueous composition based on acrylic resin with the addition of various polymers. Such a paint prevents the destruction of concrete due to corrosion, creates a protective polymer film on the surface, which prevents various mechanical and chemical influences.

The coating, which is formed by acrylic paint, is quite reliable and durable, moisture-resistant and waterproof, so it can be used to paint the floor in the garage, basement, on the balcony and stairs.

Applying acrylic paint is simple and convenient. To do this, you can use a brush, rollers or spray, and unlike epoxy paint, one layer is enough, although you can cover it with two layers for more confidence. Full drying time is 12-14 hours.

Polyurethane Enamel

Polyurethane enamels, as a rule, are two-component, however, this does not affect their high quality. They are designed to finish concrete floors both indoors and outdoors. Advantages of the paint are its high weather resistance, economy, environmental friendliness, high hiding power, excellent chemical and mechanical strength, and the formation of a perfectly smooth glossy surface.

Apply polyurethane enamel at a temperature of at least 5 degrees above zero and humidity not more than 75%. Since the paint is two-component, for a start the first component is thoroughly mixed, and then the second is added to it. It is advisable to paint the concrete floor in two stages: apply a thin uniform layer without spills and smudges, re-apply the paint, but no later than a day after the first painting of the concrete floor.

The main disadvantage of polyurethane enamel is its long drying time - 2-14 days. We can explain such a significant time spread by such moments: the paint does not stick after two days and you can walk on it, the floor covering finally gets mechanical resistance in a week, and after two weeks - chemical resistance.

Polyurethane primer

If you do not have paint for a concrete floor, then you can simply prime the surface with a polyurethane compound. The primer can be used as the only protective coating, as well as for processing the coating before applying the topcoat directly. Primers are polyurethane and epoxy.

Polyurethane primer is able to ensure reliable filling of small pores of concrete, its dust removal and hardening, as well as excellent adhesion to the coating. This substance is resistant to gasoline, detergents, chemicals, fats, oils and precipitation.

Judging by the name, a polyurethane primer is used before staining with polyurethane enamel, because they have almost identical compositions. However, the paint can be used only 12 hours after the completion of the priming of the floor. The advantages of this primer are in the convenience and ease of application, reducing the consumption of topcoat, and improving the adhesion of the topcoat.

Epoxy primer

Epoxy primer is suitable for treating concrete surfaces before applying epoxy paint to it. But it is also customary to use this primer as an independent coating, which ensures the closure of all pores and cells in concrete, as well as dust removal and hardening of the floor surface.

Advantages of the epoxy primer are water resistance, water resistance, improved adhesion of the finish coating, resistance to mechanical wear and chemicals. Before applying an epoxy primer, the concrete surface must be sanded and debris and dust removed from it. You should know that for 20-30 minutes the material is able to lose its qualities, so you need to apply it quickly enough.

Surface preparation

The operational properties and durability of the painted concrete floor depend primarily on the quality of surface preparation. First, make sure that there is no dirt, debris, old paint, stains of paints, fuels and lubricants, or bitumen on the floor. Traces of such liquids can be removed with detergents. Water on the concrete floor should not collect in drops.

It is also necessary to remove concrete chips from the floor. After that, it is necessary to seal and putty down all existing pits, and then carry out grinding using special grinders. A similar procedure can improve the adhesion of the paint layer and the base.

To get rid of dust, you can use a vacuum cleaner or an ordinary mop. As practice shows, all concrete floors are equally dusted. To prevent this process, it is necessary to dedust the concrete coating and process the top layer. Dust removal is carried out using different compositions of polymers that protect the floor not only from the presence of dust, but also from abrasion and abrasion.

They strengthen the concrete surface with impregnations of a reinforcing type, which are called toppings. These substances are presented in the form of dry mixtures of quartz, cement and other fillers, as well as plasticizers and dyes. Similar toppings can also be used with decorative intentions, making your concrete floor glossy and smooth.

The composition of the toppings clogs the pores of the concrete floor, preventing the penetration of harmful components into the surface and ensuring the stability and strength of the concrete structure, facilitating operation, which significantly saves money on coating care. This tool is usually applied to the surface 7 days after its installation. The use of reinforcing agents will increase strength and dedust the coating for 5 years.

Primer concrete floor

To ensure good adhesion of the concrete floor and paint, it is recommended that you first coat the surface with a primer. There are many varieties of this tool (Beolux Aqua, Grid), which can be used outdoors and indoors. These are acrylic quick-drying materials that are quite resistant to oils, gasoline, salt solutions, chemical detergents, mineral compounds and water.

For applying a primer, it is customary to use foam rubber rollers that allow to distribute the composition well on the floor surface. Put a primer so. The composition is mixed, if necessary, diluted to 3% of the mass of the primer itself. It is recommended to add quartz sand to the substance to avoid the effect of slippery floors - up to 10% of the primer mass.

The primer must be applied in 1 or 2 layers to a dry, clean coating using rollers, spray or brush. It is recommended to use the composition at a temperature of 5 - 40 degrees above zero and a relative humidity of 85%.

Surface painting

You have already decided how to paint the concrete floor, now you need to decide which tool to use in your work - a roller, brush or spray. The choice of staining option will depend on which paint formulation was selected. The spray paint is applied in one layer, which is able to replace 3 layers, which are applied in the usual way. This method of applying paint is quite simple, economical and takes little time.

When using a spray gun, remember that with it you will be able to process the main part of the concrete surface, and you will have to paint other hard-to-reach spots and corners with an ordinary paint brush. The paint thickness is only up to 0.2 millimeters.

Acrylic paints and enamels are applied to the floor surface using rollers. Suitable for this are wide, which have a short pile - simple front and velor rollers that allow you to apply paint evenly and quickly. To make it convenient to work, it is worth fixing the rollers on long handles. To paint the corners, use narrow small brushes.

The concrete floor is painted at a surface temperature not lower than plus 5, indoor air temperature not less than 10 degrees above zero and air humidity not more than 80%. Water-based polyurethane paint does not emit flammable and smelling substances during operation. Containers and tools are washed with water.

It is allowed to paint fresh or wet concrete, but not earlier than 5 days after pouring. When painting a concrete floor, first of all, it is customary to apply strokes in different directions, then the paint is rubbed on the surface. Layers of the coloring composition should not be too thick: thin layers dry faster and look better.

The creation of thicker layers leads to a long drying time of the coating. Make sure that the previous coat is completely dry, and only then proceed to applying the next coat of paint. Application of the second layer is allowed only after 24 hours.

Floor drying

After the concrete floor painting procedure, it is recommended to wait until the painting composition has completely dried out. This process should occur at a humidity of 70-80% and air temperature plus 18-20 degrees. Only after 3 days are mechanical loads allowed, but if the conditions differ from those presented, then the drying process of the concrete floor can take a longer time, or faster.

The duration of the drying of the coating also depends on the conditions under which the paint was applied. For example, if the coloring matter was applied to fresh concrete, the drying period will increase significantly. Under normal conditions, the polymerization of the coating finally takes place on the seventh day, when the maximum mechanical and chemical stability indicators are reached. Therefore, do not rush to use the surface as quickly as possible, let it dry completely so that it acquires the proper wear resistance.

Thus, concrete paint is able to increase the strength of the coating, protect it from dust and increase the waterproofing of the screed. But all this is achievable only if the right choice of the coloring composition is made. In addition, the sequence and competent execution of all stages of painting the concrete floor is of great importance.

Concrete floor protection

Concrete floors are still very popular in the construction of industrial and commercial buildings. In addition, they are quite common in home workshops, cellars, garages, in various outbuildings, sheds and pantries.Even though this highly durable material is able to withstand enormous loads in less than favorable conditions, it still needs protection.

Concrete has high porosity and low tensile strength, which leads to the destruction of its upper layers under the influence of external factors. If low-quality concrete from low-grade raw materials was laid, then quite often characteristic dust appears during the wear process.

To protect the concrete base, special formulations are often used. They not only give the surface a decorative color, but also protect it from destruction due to the influence of aggressive environments and inevitable wear. In addition, such a surface does not slip, it becomes hygienic, antistatic, more even.

Selection of paint for concrete

The floor screed must be painted with alkyd or epoxy paints - they do not slip, are antistatic and are not afraid of the effects of chemicals. Epoxy paints must be prepared and mixed before use, after which you can start painting. Alkyd substances do not need preparation. The only thing to do in this case is to carry out the primer of the base, but for epoxy paints, the primer is not needed.

Before painting a concrete floor, it must be primed. Such compositions are widely used and allow you to restore the floor even in a neglected state. The tinting impregnating mixes make concrete bright, giving color. Polymers are able to hide all irregularities, and thanks to special putties, the surface comes out truly monolithic. The base can be decorated with glitters, flocks that do not lose their appearance under the influence of sunlight for a very long time.

The color of the concrete floor depends on the characteristics of the room. If you are setting up a production workshop where mechanical damage is not excluded, you will need to create a floor with enhanced reliability. In this case, wear-resistant paints are the best fit.

If you do not know how to paint a cement floor of small thickness, then it is best in this case to choose a varnish for concrete floors or polyurethane enamel. For painting concrete floors in garages and landscape buildings, mixtures for industrial premises containing solvents and epoxy enamels are used (more: "Painting concrete floors in a garage: nuances and tips").

Water-based mixes are needed to cover concrete floors in a residential area. For the decoration of balconies and corridors, it is better to pay attention to two-component polyurethane elastomers. Polyurethane dyes will be needed if it is necessary that the working surface is moisture resistant. It is worth considering each of the types of dyes for concrete substrates separately.

Concrete floor painting

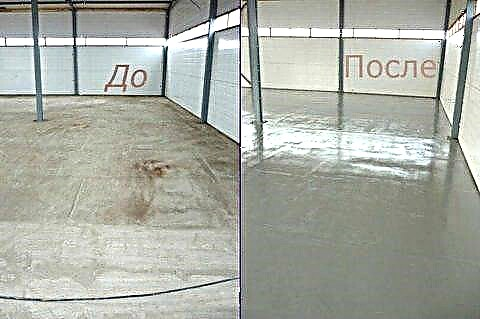

The purpose of the varieties of compounds is already known. In any case, the principle of applying paint remains, by and large, unchanged. First, the base is prepared - it is cleaned of debris and dust, after which all flaws are putty, and the primer is applied. After these events, it is already possible to produce coloring. It should be noted that concrete floors, as a rule, are covered in several approaches, applying 2-4 layers.

Foundation preparation

How long the floor will last, primarily depends on the quality of the preparatory phase. Make sure that all rubbish, the remains of old paint, dirt, bitumen, stains from varnishes and all kinds of fuel and lubricant mixtures are cleaned from the base. It is not difficult to remove such marks with detergents until the water on the floor stops collecting in separate drops.

All crumb of concrete should be removed from the floor, after which you can begin to putty all the cavities, and then grind with any special grinding machines (read: "How and how to grind the concrete floor - instructions for self-fulfillment of work"). These measures will improve the adhesion of the finish layer to the floor. It is best to remove dust with a vacuum cleaner, at worst - with a simple mop.

Toppings are used as reinforcing impregnation. They are dry mixes, which includes quartz, cement, plasticizers, dyes and other additives. Reinforcing mixtures can be used as a decorative floor treatment, making it smooth and glossy.

Toppings close the pores of concrete, preventing harmful substances from penetrating into its upper layers. Thus, the maximum strength of concrete and its performance are ensured. At the same time, the cost of caring for such a floor is significantly reduced. Such a mixture can be applied a week after installation of the base, as a result, dust removal of the surface occurs up to 5 years.

Concrete floor primer

In order for the adhesion of the paint to the concrete base to be extremely high quality, it should be opened with a primer. There are many types of this product on the market, used both indoors and outdoors. These include quick-drying acrylic oils that are resistant to oils, gasoline, salt solutions, chemicals, minerals and water.

Foam rollers are best suited for priming, which cope perfectly with the distribution of the composition on the concrete base. The primer is applied as follows: the composition is thoroughly mixed, in special cases it is diluted with 3% water. It is advisable to add quartz sand to the primer so that the floor is not so slippery - no more than 10% by weight of the primer.

For coating with a primer, 1-2 layers are sufficient, while the floor must be dry. It is recommended that work be carried out at an air temperature of 5-40 ° C and 85% humidity.

Floor drying

After the floor is painted, you need to wait until the floor is completely dry. This stage should take place at a relative humidity of 70-80% and an ambient temperature of 18-20 ° C. It is allowed to expose the base to mechanical loads only after 72 hours have passed. If the drying conditions were not so ideal, then this time may increase slightly - and, conversely, under more favorable conditions, the period may be slightly reduced.

The duration of drying also depends on the conditions that accompanied the process of painting the base. For example, if staining was carried out on fresh concrete, then drying will take significantly longer. If normal conditions were met, then the complete polymerization of the base occurs about a week later, after which the coating acquires the maximum possible mechanical and chemical indicators of resistance. Therefore, it is in your interests to give the base as long as possible drying time, so it will last as long as possible.

Now everyone knows how to paint the concrete floor, what tools are needed for this, and how much time is required to give the base maximum performance. As a result, the upper layers of the concrete floor will not turn into dust and absorb moisture.

It is very important to choose the right coloring materials, try not to save, make a primer, if this is highly recommended. Do not buy materials from unverified manufacturers, in addition, if they are suspiciously cheap. At the same time, it is important to comply with all technological steps for painting, accuracy and experience, and then the concrete floor will be operated for as long as possible.

Why paint concrete floors?

Concrete floor coverings are rightfully considered durable, so many people think that surface protection is not required. As a result, after several years of use, the floors become unusable. This is due to the fact that in the structure of concrete after solidification there are small air pores that are able to absorb moisture. When the room temperature drops below 0 0 C, the absorbed water even freezes in small amounts and destroys the surface layers, forming cracks and worsening strength characteristics. On the other hand, with large flows of people or vehicles in the room, the load on concrete increases, it wears out and concrete dust is formed harmful to human health. In places of increased wear, depressions associated with friction appear.

What properties should paint have?

Before painting a concrete floor, it is necessary to understand what properties a protective coating should have:

- High adhesion to concrete, which ensures reliable adhesion to the floor, does not peel off at temperature changes and does not peel off.

- Have increased abrasion resistance.

- To carry significant loads.

- Do not lose decorative properties during the entire period of operation.

- Improve surface characteristics: protect from chemical attack, reduce slippage, increase moisture resistance.

In the photo, concrete floor painting

What paint to choose?

When choosing a paint, one should be guided by the features of the premises: the load, room temperature, moisture, exposure to various chemical compounds. Depending on this, certain compositions of coloring substances are selected. For commercial premises with a thick layer of bulk floors, wear-resistant paints will be most suitable. If there is a thin leveling layer, polyurethane-based varnish or enamel is suitable. If it is supposed to paint floors in industrial premises, then epoxy compounds are used.

In homes and apartments, water-based formulations or two-component polyurethane paints can be used.

Epoxy enamel

Painting the concrete floor with epoxy paints will create a durable floor covering and provide it with excellent decorative properties. It can perform a waterproofing function and protect concrete from moisture, which is relevant for painting open parking lots and public places. High-quality adhesion to the floor surface will provide resistance to paint abrasion and concrete wear. Increased loads are also not afraid of her. To acids and alkalis, the paint is neutral and does not react with them, so it can be used in warehouses with chemicals. Over time, the surface does not lose color.

In the photo, the concrete floor is painted

Polyurethane based paint

This type of paint is highly resistant to atmospheric precipitation. Allows you to create a coating that protects against mechanical and chemical influences, due to its adhesive properties. It is able to penetrate even the smallest cracks and pores of concrete, because it has excellent wettability. As a result, even the smallest surface defects will be saturated with paint and will be able to provide reliable protection for concrete. It forms a smooth glossy layer on concrete with excellent decorative properties. Due to the two-component composition, mixtures with the necessary consistency and properties can be kneaded. The disadvantages include a long drying time and the need to apply two layers of paint.

[rek_custom1]

Acrylic enamel

Painting the concrete floor with water-based acrylic enamels allows you to create a polymer film on the surface that reliably protects concrete from water, acids, alkalis. When applied, it can dry for several tens of minutes, depending on environmental conditions and the thickness of the applied layer. The colors are rich and vibrant, so applying a single coat of paint is enough. It does not fade in the sun and retains its decorative and mechanical properties for a long time. Withstands both high and low temperatures. Over time, the coating does not crack or peel. If it gets into an undesirable place, it is easily washed off with water, and not with a solvent, as is the case with other types of paints.

White paint

Preliminary floor preparation

To improve the adhesion of the coating to concrete, it is necessary to carefully prepare the surface. The first step is to remove dust and dirt from the surface with a damp cloth. If the paint was applied earlier, then it is cleaned with a spatula, grinder, or a drill with a special nozzle. At the same time, you need to be careful and not cause mechanical damage in the form of scratches and waves, which after painting will immediately catch your eye. Oil and grease stains are removed with solvents. The floors are also checked for cracks and flaking areas, which should be repaired locally or completely filled with a new coating. The floors must be dry before painting.

Priming

The concrete floor is painted after the obligatory application of a layer of soil mixture. This is done in order to remove dust from the surface and create conditions to ensure maximum strength of the painted layer. At the same time, the impregnating compositions are intended for hardening concrete, since they are able to penetrate deep into the structure and block pores.

Primers are selected depending on the type of room: for internal processing or external.

First, the solution is thoroughly mixed to achieve a homogeneous mixture. If necessary, add quartz sand to 0.1 part of the total to prevent slipping. Application is carried out with foam rubber rollers in one or two layers at a temperature above +5 0 C.

Concrete floor painting with marking

Concrete floor painting procedure

The selection of suitable painting tools is selected based on the area of the room, as well as the type of paint chosen. For applying polyurethane paint over large areas, a spray gun is used that has high productivity and is able to evenly paint floors. This technique will save time and money due to the fact that it will be enough to have one coat of paint, in contrast to manual painting. However, for inaccessible places, you may still need a small brush. Acrylic and epoxy are applied with a wide roller with a small pile. It is allowed to paint concrete poured a few days ago, which has hardened.

Coating drying

When painting the concrete floor is completed, it is necessary to create all conditions for drying of the paint. The room temperature should be from +18 0 C, and relative humidity less than 80%. These conditions will ensure uniform drying throughout the day. After 48 hours after painting, the floors can withstand full loads. Full solidification and the acquisition of protective properties will come only in a week.

General information

On the modern market of building and finishing materials, a rich assortment of products is presented that can be successfully used for painting a concrete floor. When choosing a particular option, it is necessary to take into account not only the personal preferences of the owner and the affordable budget, but also the purpose of the premises. You can find brief information on this in the table.

Table. The choice of paint for finishing concrete floors

| Composition | Operational Features |

|---|---|

| Epoxy and acrylic compounds | They differ from their “brothers” in antistatic and anti-slip properties. Great for painting the structures in question in a wide variety of rooms. Finishing materials provide surface resistance to chemicals and guarantee a wonderful appearance of the structure. The epoxy composition must be prepared before application, in the case of the use of alkyd paints, this is not necessary. Along with this, the base must be primed before surface treatment with alkyd. When using epoxy paint, you do not have to do this. |

| Primers | Allows you to restore the appearance and performance of a running concrete surface with noticeable signs of wear. |

| Tinting agents | Special impregnations to give concrete any desired color. In most cases, they are used in combination with other means described in the table. |

| Polymer Compounds | Allows to hide irregularities and other surface defects. With this tool, any concrete floor can be solidified. |

| Flocks and Glitters | They make the surface look more decorative, providing additional protection for the floor from ultraviolet exposure. |

| Wear Resistant Compounds | The best solution for rooms with frequent high mechanical loads. Contribute to a significant increase in surface strength and extension of its service life. |

| Polyurethane enamels and varnishes for concrete | They are mainly used in home construction for the finishing of thin coatings. |

| Dyes based on epoxy enamels and solvents | Usually used in garages and other rooms with similar operating conditions. |

| Water based paints | Best suited for flooring in living rooms. |

| Polyurethane Elastomers | Used in hallways, hallways, on loggias and balconies. |

| One-component polyurethane products | A great choice for rooms with high humidity. |

Next, a more detailed overview of the compositions most commonly used in private house-building will be given, and general instructions for painting the concrete floor, relevant for all the means considered, will be given.

Epoxy based paints

The epoxy does not wear out and does not turn yellow, even if you cover the concrete floor in hangars, production shops, car repair shops and parking lots

Correctly applied coating will retain its original appearance for a long time, while ensuring high strength and durability of concrete pouring in parallel with this.

Epoxy compounds withstand various external influences, including aggressive chemicals. Combustive-lubricating mixtures, alkalis and acid solutions, water, etc. - all of the above does not cause particular harm to the coating.

Quality epoxy paint for concrete floor

Perfectly adhering to the surface, epoxy paint normally copes with mechanical influences without yellowing or abrasion during operation. Its effectiveness has been repeatedly confirmed even when used in various workshops, workshops and other similar places.

Paint can be used both indoors and outdoors. At the same time, it can be applied even over incompletely dried concrete, which can significantly save the time spent on finishing work.

Epoxy paint is used even for marking

The main disadvantage of the epoxy is the two-component composition, i.e. Before use, this product must be prepared. Usually there is no problem with this, as manufacturers provide their products with detailed instructions, but they have to spend extra time. There may also be difficulties in the process of repainting the floor. For example, if the owner wants to change the color of the surface, it will be very difficult to do this.

Although the possibility of painting with an “epoxy” of a partially dried paint was previously mentioned, it is better to treat the base with a primer made on an epoxy base before applying the composition. If desired, this tool can be applied as an independent coating. Preliminary finishing with a primer will close concrete pores, dedust the structure and increase its strength.

Among the additional advantages of using an epoxy primer before applying a paint composition on a similar basis, it is worth noting an increase in the waterproof and water-repellent properties of the floor, as well as an increase in the adhesion of the selected paint to the base.

Epostone two-component epoxy water-dispersion primer-enamel for concrete floor

Before applying the primer, the surface is ground. Also, it must be cleaned of debris and dust.

Grinding - an obligatory stage of work before applying epoxy compounds

Important! The finished primer mixture loses its properties for about half an hour after preparation, so it is important for the contractor to learn how to correctly calculate the speed of work and material consumption.

Acrylic paints for concrete floors

Acrylic paints for concrete floors

After applying such a tool, a polymer film forms on the surface, which increases the resistance of the structure to chemical, mechanical and other adverse effects and loads.

At the same time, the composition tolerates moisture contacts well, is durable and wear-resistant, which allows it to be used even in private garages, basements and other rooms with similar operating conditions.

Composite (Kompozit) AK-11 - acrylic paint for concrete floors on an organic basis Composite (Kompozit - Ukraine)

Acrylic coloring agents are extremely easy to apply. Finishing can be done using rollers, brushes and special sprayers. In the case of using acrylic paints, in contrast to the previously considered epoxy-based products, a single-layer coating is sufficient. If desired, you can apply paint and a double layer for greater peace of mind of the owner.

Polyurethane enamels for concrete

Enamel for concrete surfaces gives them not only an aesthetic appearance, but also improves performance

In most cases, they are sold as a two-component mixture. They are characterized by high quality and can be used both indoors and outdoors.

Such paints are characterized by high indicators of environmental friendliness and profitability, they are resistant to atmospheric, mechanical and chemical influences. After processing, the surface acquires a perfectly smooth, smooth and glossy appearance.

Enamel applied on the floor

It is important that the air humidity when applying polyurethane enamel on concrete does not exceed 75%, and the temperature is at least +5 degrees.

As noted, the composition is two-component. In view of this, before starting work, the composite ingredients must be mixed. First, the first component is thoroughly mixed, after which the second component is added to it.

Polyurethane enamel for concrete Polyflex 1101

The main disadvantage of this paint is the long term of its complete drying. Depending on the manufacturer and the characteristics of the composition, this can take from 2 days to 2 weeks. In general, the paint stops sticking after 2-3 days. After the specified time, you can safely walk on the surface. Full mechanical strength is gained in a week, and the chemical resistance indicator reaches its maximum after 14 days.

Before applying polyurethane enamel, the floor is recommended to be treated with a primer made on the basis of similar components. Between priming and painting, a 12-hour break must be maintained. The polyurethane primer is extremely simple and easy to apply. Its application provides high adhesion of the finish layer to the base and contributes to a marked reduction in paint costs.

Distribution of polymer soil with a velor roller

In this case, the composition fills small pores, contributing to an increase in the strength of the base and dedusting it. The primer withstands contact with gasoline, oils, fats, various chemicals and detergents, etc.

Concrete Floor Step-by-Step Guide

Concrete Floor Step-by-Step Guide

You have received information about the main characteristics and features of the application of the most popular paints for concrete. Regardless of the chosen product, the procedure for applying paint remains virtually unchanged. First, you prepare the floor for the upcoming work, eliminating any dirt and dust, then primer and putty the base, getting rid of all sorts of bumps, and finally apply the chosen coloring agent and allow the composition to dry. Next, you are invited to familiarize yourself in detail with the nuances of each stage of the work.

First step. Preparing the floor for painting

The basic operational properties and the service life of the finish coating largely depend on the correctness and quality of the preparatory stage.

Start with garbage, traces of old paint, all kinds of dirt, stains, bitumen, etc. To eliminate various stains, the surface should be thoroughly washed with special detergents. According to the results of processing, perform a simple check: pour some water on the floor and, if it is not going to drop, you can continue.

Remove old paint, traces of oil and dust from concrete.

The surface must be thoroughly cleaned of concrete chips. Once rid of debris, seal cavities, cracks and cracks with putty. Get rid of the protrusions with a grinder. Remember: the smoother the floor, the better the paint will lie.

Putty concrete floor

Dust can be removed using a vacuum cleaner or an ordinary mop with a wet rag. Experts strongly recommend treating the surface with dust-free impregnation. Thanks to this, the floor will not become dusty in the future. Additionally, such impregnations increase the resistance of concrete surfaces to abrasion and moisture.

Protexil - hardening and dust removal impregnation for concrete floors

Pre-treatment of the floor with a special topping designed to increase the strength of the structure will not be superfluous. Toppings are sold in the form of dry mixes on a cement, quartz and other basis. Additionally, coloring pigments and plasticizers may be included in their composition. Thus, using topping, you can not only strengthen the surface, but also give it a more aesthetic appearance.

Second phase. Primer treatment

Before painting the floor is recommended to be primed. A specific tool should be selected taking into account the composition of the paint used.

Read the manufacturer's instructions first. Its provisions will help you understand the preparation and application of the product - these points require individual clarification, as they vary depending on the particular composition.

In general, the primer can be quickly and conveniently applied using a foam roller - this simple tool ensures even distribution of the product on the floor.

Primer treatment

Experts often add quartz sand to the primer. It accounts for an average of 0.1 of the weight of the primer. The floor treated with such a mixture will not slip.

| Name, weight | Description | Drying time | Consumption kg / m2 | Cost |

|---|---|---|---|---|

| Universal acrylic soil, 10 l | Suitable for concrete, cement-sand and gypsum substrates, strengthens the surface layer, reduces diffusion ability | 1 hour | 10 | 151 rub |

| Soil BOLARS Concrete contact, 12 kg | Suitable for concrete, stone, plastered surfaces, increases adhesion | 15 hours | 0,3 | 712 rub |

| Soil for the absorbing bases CT17, 5 kg | Suitable for concrete and cement-sand screeds, has antifungal properties, elasticity | 4 hours | 0,2 | 251 rub |

| Concrete contact Axton, 18 kg | For processing smooth concrete substrates, increases adhesion | 2 hours | 0,25-0,3 | 788 rub |

| Adhesive primer GLIMS BetoContact, 4 kg | For processing smooth concrete substrates, floor tiles | 24 hours | 0,3 | 272 rub |

The primer itself is applied in 1-2 coats, depending on the initial state of the concrete surface. For application, you can use not only rollers, but also brushes. Sprayers are also suitable. The choice of the instrument is up to the contractor - as he sees fit. The optimum temperature and moisture indicators for priming are as follows:

- air humidity - up to 85%,

- temperature - within + 5- + 40 degrees.

The third stage. Painting

The choice of paint remains at your discretion - earlier you studied the characteristics of the most popular formulations and you probably made the right choice. It remains only to choose a device for applying a coloring agent and you can begin to do the work. There are 3 options at the discretion of the artist: brushes, various rollers and a special spray.

It is important to know that one layer, equipped with a special sprayer, in its characteristics corresponds to 2-3 layers of the coloring composition applied by hand tools. In this case, if you use the sprayer, you can save not only time, but also the paint itself. However, it will not be possible to completely abandon the use of brushes and rollers - corners and various inaccessible places cannot be processed with a spray gun.

Concrete floor painting

For applying acrylic paints and enamels considered earlier, wide rollers with a long pile are traditionally used. Such a device makes it possible to relatively quickly and fairly evenly apply the composition, providing high quality work. For convenience, it is recommended to attach a long handle to the roller. Inaccessible places and corners paint over with a small brush.

Inaccessible places and corners paint over with a small brush

The technology of work is extremely simple:

- if necessary, the paint is prepared for application in accordance with the provisions of the manufacturer's instructions,

- smears are applied to the surface in various directions,

- the composition is evenly distributed along the base.

Helpful advice! Do not apply dye too thick. It is better to make a thin coating - it will dry out much faster and will have a more presentable appearance. Each new coat of coloring agent can be applied only after drying of the previously created.

The fourth stage. Drying

The paint applied must be allowed to dry.

The applied paint must be allowed to dry. Information regarding the duration of drying and the necessary temperature and humidity conditions is recommended to be specified separately in the attached manufacturer's instructions. Standard recommendations are as follows:

- temperature - within + 18-20 degrees,

- humidity - 70-80%,

- Duration - from 3 days. After this time, the paint can be subjected to mechanical stress. If the temperature and humidity conditions differ from the recommended, the drying time of the finish will also change.

In addition, the drying conditions are influenced by the conditions under which the finish was carried out. For example, if a fresh concrete floor has been coated with paint, drying will take much longer. Under normal conditions, the coating will completely polymerize after about a week. During this period, the material reaches maximum resistance to chemical and mechanical influences.

Thus, a correctly selected composition for painting concrete will contribute to a significant increase in the strength of the structure, additionally providing its reliable protection against dust, moisture and other adverse effects. The contractor is only required to adhere to the recommended sequence of the event.

Why paint concrete?

Most often, a concrete screed is protected by a layer of decorative material, for example, ceramic tiles or laminate. But in household or industrial premises, such protection is not effective or its device is not practical from a cost point of view.

Therefore, to protect surfaces from physical and chemical influences in garages or sheds, concrete floors are painted.

But is it important to protect concrete? The cement-based screed is quite strong, but has a porous structure. If you do not close the top layer of the coating, then over time, the screed will begin to break down and lose integrity.

The destruction process is due to the fact that the hardened cement mortar has:

- The porous structure in bulk. Concrete absorbs any water from the surface or from the air in the room. As a result of temperature changes, the water in the pores will change volume and destroy the screed from the inside.

- Low resistance to weight and physical effects on the surface. As a result of such loads, the concrete is stratified and dusted.

On a note! The lower the grade of cement used for mixing concrete, the less the surface of the screed will be less resistant to destructive effects.

The benefits of using paint

As already mentioned, any concrete surface requires external protection. But, as a rule, durable and resistant decorative materials has a rather high cost.

Concrete painting is the most economical protection solution, because it preserves the strength characteristics of concrete and performs the following necessary functions:

- provides an increase in the strength of the screed and, as a result, extends the service life of the coating,

- minimizes the possibility of delamination or cracking,

- protects the concrete screed from abrasion,

- sets a barrier against the effects of chemically active substances,

- increases antistatic characteristics of concrete.

Choosing which paint to paint the concrete floor, you can solve some more operational issues:

- make the surface non-slip, reducing the risk of possible injuries,

- to simplify the process of maintenance and cleaning of the floor,

- make the room more comfortable, modern paints have a very rich color palette.

On a note! Different coatings (paints and varnishes) require different conditions for application. Before use, carefully read the manufacturer's recommendations. Instructions for use are always indicated on the label.

Concrete painting technology

Despite the fact that the indoor conditions may vary depending on the type of paint used, the stages of the work are always the same. And before describing how to paint a concrete floor, we will consider what activities need to be carried out.

In total, it is worth highlighting 4 stages of the work:

- preparation, surface cleaning,

- primer or primer treatment

- coloring

- drying.

Primer application

There is nothing complicated in the processing of concrete with a DIY primer. Work on applying the composition to concrete should be carried out at an indoor temperature of more than 5 0 C and a relative humidity of less than 85%.

It is very important to observe the following rules.

The solution should be applied:

- plentifully

- in several layers (at least two),

- over the entire surface, avoiding "white" spots.

Important! Before applying the primer, carefully read the instructions on the label, some primers require additional solvent.

In order to increase the surface roughness, quartz sand can be added to the primer solution. The permissible amount of inclusion is not more than 10% of the initial volume.

The composition is applied to the surface using a roller or spray. It is recommended to treat the floor along the perimeter of the room with walls with a brush, this will provide a better degree of protection.

Popular primer formulations

Before you properly paint the concrete floor, you must choose the appropriate primer in composition.

The most commonly used primers are 3 types:

| Type of primer | Characteristic | Photo |

| Polyurethane | Used in conjunction with polyurethane paint. The composition is very easy to apply, does not require special preparation before use. Operational advantages of using this type of soil: |

- fills small sinks and voids,

- improves concrete adhesion,

- fast drying time

- protects against the action of active chemicals.

Processing with a polyurethane primer concrete screed significantly reduces the required amount of paint.