Home-made furniture is not an easy task, however, it is the skill of building interior items from nothing that will allow you to create a unique atmosphere in your own nest. Indeed, caring for a home hearth consists not only in cooking, filling the interior with comfortable trifles, but also in harmoniously completing the furniture used. In addition, the ability to independently assemble a table is very useful also in the case when you have a limited budget, and your new housing is completely empty. You may be surprised, but it is the creation of small details of interior items that always requires special concentration. Therefore, let's talk about how to make table legs with your own hands with professional precision.

How to make table legs with your own hands?

Functions of table legs

It would seem what functions the legs of the table can carry, because this is just one of the elements of dining furniture. However, in fact, it is precisely these structural details that can completely affect your comfort level in completely different ways.

Table 1. What functions are table legs

| Function | Description |

|---|---|

| Supporting | Of course, the legs are the support of the structure. It is on their quality, strength and proper manufacturing that will determine how stable the table will be on the floor. They can prevent: |

| Decorative | Table legs do not have to be simple and smooth at all, they can become a highlight of the entire interior of the kitchen or dining room. The fact is that the countertop is often covered with a tablecloth, plus you won’t be particularly scattered with its design, because it should still be convenient to eat food, hold a laptop, etc. |

| Adjusting | Some table legs can adjust the following table position parameters: In other words, even if you have a completely uneven floor using such devices, you can level out its shortcomings. |

| Transformer | Thanks to folding legs, a small coffee table can at any moment turn into a large dining table, and vice versa. This is very convenient when a small number of people live in the apartment who do not have a constant need for a dining surface. |

| Protective | It is the legs that protect the lower segments of the table from mechanical stress, taking a hit on themselves, thereby minimizing the wear of the structure. Exactly how high-quality and strong the legs will be will subsequently determine the durability of the product. |

The table legs are not just a support, but a rather significant detail that determines the overall quality, appearance, service life and functionality of the table

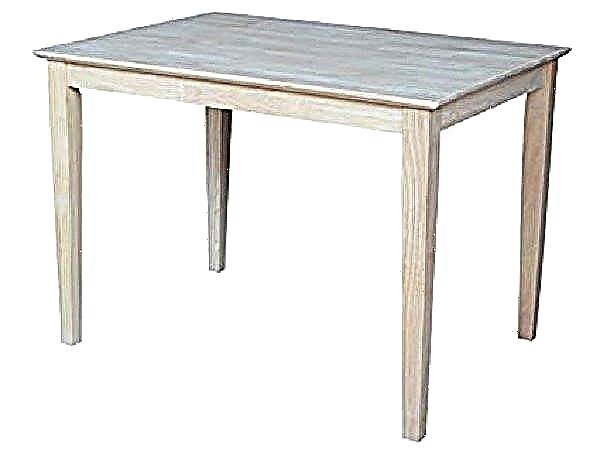

Standard legs

Standard products are, simply put, ordinary coasters that are not endowed with such specific functions as:

- tilt adjustment

- height adjustment, etc.

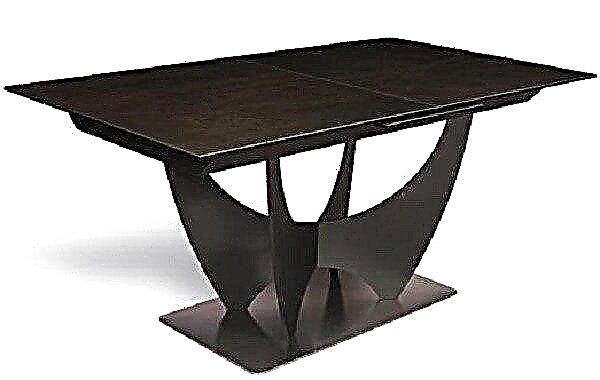

A table with standard legs fits into any interior

The advantage of the legs of the traditional type is their reliability, since their only purpose is to be a support. Of course, they may not be without a decorative design, but more and more such supports are implemented in a rather laconic form, so that they have the opportunity to fit perfectly into any interior. However, for those who choose these, the democratic value is clearly more important than the external beauty of the products.

Tables with such legs can be installed not only in the kitchen or dining room, but also in the office, student’s room, office, living room, etc.

Standard legs do not have to look cheap

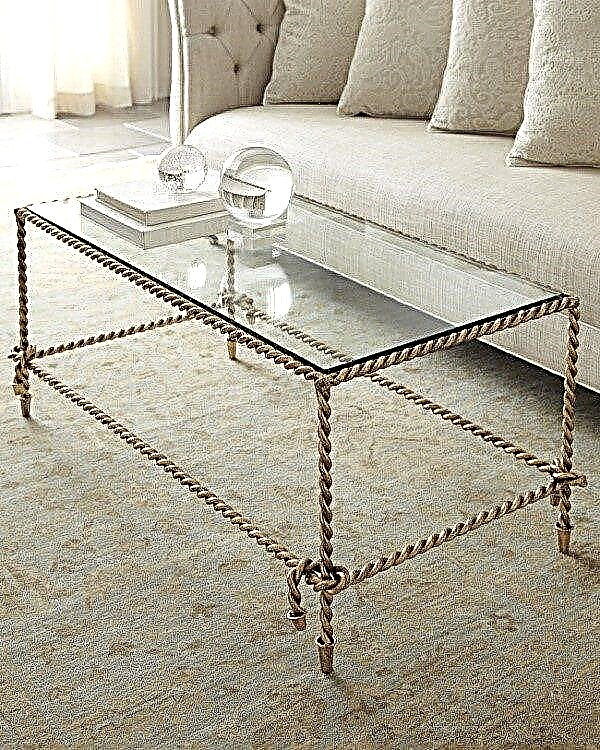

Decorative legs

Decorative legs are an integral part of the overall appearance of the table, as well as the interior of the room in which this piece of furniture will be installed. Today there are many tables with such legs, literally for every taste: from classics to original decor.

Decorative legs can be the highlight of the interior

Handmade legs, curly, carved, intricate in shape, having a different color and design, are especially valued. They differ, as a rule, also in their elegance, and can be attached to tables of any orientation:

There are an incredible variety of different decor options.

Some people first fall in love with a table with painted legs, then buy it and then build their entire interior on them so that everything fits together.

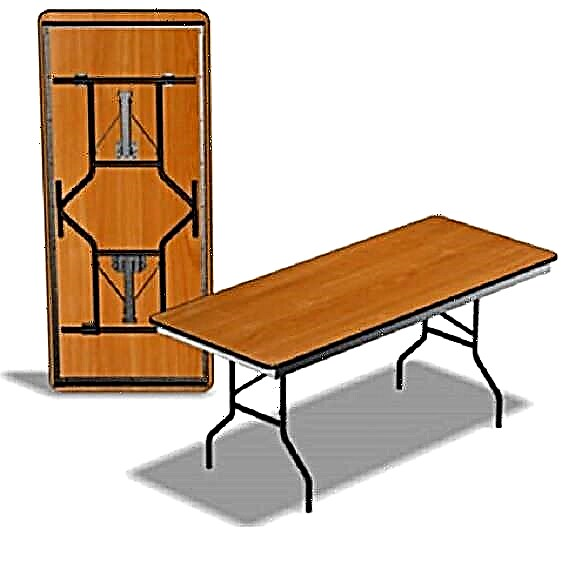

Folding legs

Tables with such legs are most often installed in the offices of eminent companies in order to make the workspace the most convenient for people using this interior item.

However, in fact, you can put such an unusual model in any room of the apartment, making using the table several times more convenient. This is especially true for modest spaces in which in addition to the table you need to fit at least a few more chairs, cabinets, etc.

Foldable legs add functionality to the table

The significant advantages of folding tables are:

- low cost

- ease of transportation

- convenience of placement

- the ability to use anywhere.

Of course, if you want to fit at the table with a huge family at lunch time, it is better not to take risks, and take the option a little more stable.

Table with folding legs - a stylish and functional product

Telescopic legs

The legs of the telescopic type allow you to adjust the furniture to the extraordinary requirements of its owner. So, using tables equipped with telescopic legs, you can adjust:

- countertop height

- angle of inclination of the structure.

Very often, they prefer to buy such tables in families with small children, since literally in one movement a spacious dining table can turn into a convenient platform for drawing a child.

Simple telescopic table maximally functional

Often, coffee tables are also equipped with such legs in order to give them functionality and make attractive for connoisseurs of the ergonomic distribution of free space in the apartment.

At the same time, the presence of a telescopic mechanism does not mean that the interior of the apartment where the table with such legs is installed must necessarily be futuristic, no, there are options that are suitable for almost any design.

Such a telescopic table is appropriate even in a simple interior

Metal

The legs made of metal are very durable, in addition, their appearance is also very attractive. Installing such parts will provide you with a long table service.

A table with forged legs is able to add a unique charm to the room

So, the legs from:

It is these metals that can hold even a massive countertop with serious support.

By the way, these legs look very impressive as a part of the interior of almost any orientation.

Often, for the manufacture of these parts, chromium is used, which has a large weight, however, its strength is found along with that for aluminum. The appearance of chromed legs is considered especially stylish, so such coasters are very actively used to create hi-tech interiors, for example, as well as loft, techno, etc.

Metal legs are not required to be standard supports. No, they can be given absolutely any shape:

Quality forging creates real works of art

Moreover, metal products are usually:

- add up

- move apart

- are adjusted to the desired parameters.

A table with chrome legs will be the highlight of the interior, despite its apparent simplicity

These legs are represented by pipes with different diameters, usually about 40 millimeters. The wall thickness of each pipe, as a rule, is one and a half millimeters. Inside these metal pipes have:

The pipes themselves are necessarily painted in various technological ways.

Forged furniture with glass countertops is very popular today. Such furnishings are literally a "squeak of fashion."

Tree

Also quite often table supports are made of wood. In this case, of course, legs made entirely of solid wood are especially appreciated, since they:

- serve for a long time

- reliable

- environmentally friendly

- look expensive and stylish.

Classic table with wooden legs

Sometimes supports are made of timber, which subsequently may not even be processed with paints, but only covered with a protective layer of varnish. Such legs become an integral part of the interior of the premises of the following styles:

Supports for a table made of wood create an indescribable atmosphere of comfort in the house. It doesn’t matter if you own a modest apartment in the city, or if you went to live in the fresh air outside the metropolis, this detail will fit perfectly into your home.

It is worth noting that wood is a valuable material, therefore, very expensive. Its use as a part of a table case significantly increases the price of furniture.

Unusual wooden table

However, for those who certainly want a table with wooden legs, but cannot spend all their monthly salary on it, the following options were invented:

- table legs made of inexpensive wood and metal inserts,

- own production of legs, the detailed instructions of which we provide below in this article.

Plastic

Plastic legs are a much less reliable option than metal or solid wood, however, it is much cheaper and available to almost everyone.

Another plus of plastic table supports is their elegance. The fact is that low quality products manufacturers usually seek to compensate for their attractive appearance.

Tables with plastic legs - a super budget option

In addition, since it is quite simple to produce anything from plastic, the legs made with his participation are also usually laid out using telescopic technology or in another way. Typically, tables with such props are equipped with:

Nobody will put such tables in elegant rooms with expensive furniture, as they will stand out sharply from the rest of the luxury.

Plastic tables are often installed in the garden or on the terrace

A rock

Another variation of the luxury table legs are stone props. This is a wonderful, environmentally friendly design, which will give solidity not only to the kitchen or dining room, but also to your personal account. The stone will serve you faithfully for many years, possibly even being inherited from family to family.

The stability of the table with stone legs is maximum, and he is also beautiful. However, you need to understand that you can’t easily move it on your own, because the weight of the structure will be significant. In addition, it must be said that the initial price of such a piece of furniture will be really high.

Not everyone can afford a table with stone legs

Another practical and at the same time low-cost version of the material from which the table legs are made is chipboards, or, more simply, plywood.

A plywood table is a great solution for a small budget for home furnishings

As you know, the following qualities can be attributed to plywood:

- durability,

- moisture resistance

- resistance to mechanical damage,

- practicality,

- low cost

- high assortment of various decorated panels.

Tables made from this material can look stylish, and at the same time be an order of magnitude cheaper than their wooden counterparts. Legs made of plywood can withstand a solid weight category countertop.

Spacious and durable plywood coffee table

Regardless of which material will become the basis for the manufacture of the table, it is preferable that lining of any soft fabric or rubber be attached to its supports, for example, so that they protect the floor surface, as well as the legs themselves, from damage during contact.

Molding table linings

It is very important to use pads made of such an environmentally friendly material as felt. They stand very democratically, while the effect they bring is really worth praise. So, their use allows you to extend the life of the product for which you have lunch or work, at least 4-5 years. Forms of overlays can be very different. The easiest way is to buy universal round or square blanks, and then cut them to the shape of the legs for your table.

Rectangular and square supports

The traditional version of the supports is rectangular. Typically, legs of this shape are very high. They taper slightly from top to bottom, but they can also keep their width along the entire length.

The most ordinary table with rectangular legs

Square supports are most often mounted on small children's or coffee tables, thus making their appearance elegant and neat.

Non-traditional forms

Unconventional forms of legs can be anything, it all depends on the imagination of the manufacturer. So, products are often found in the form of:

- polygons

- triangles

- balls

- bends, etc.

Table with woven legs

Carved legs, forged, convex or concave - the imagination of the author of the product, as well as its buyer is not limited to anything.

Color scheme

As a rule, the color of the legs is chosen to match the countertop, however, the use of shades is also actively practiced:

- several levels darker

- more contrasting.

So, for example, metal legs are often set to a table with a wooden tabletop, they are often forged, and contrast with the wood with a touch of refined metal externally.

Dining table with black legs

Often the legs are specially coated with the following shades of paint:

Legs made of natural wood or painted under a tree, stone, as well as just light and pure white look very expensive.

Legs of a black shade are most often mounted on office desks, since this color is considered an integral element of a business style, and at the same time, their cover can be made:

Black office desk

How to make table legs with your own hands: instructions

So, to make the legs for the table with our own hands, we will need to study a simple instruction. Everything is indicated in it specifically for beginners in this field who do not know which side to approach the solution of the task set before us. So let's get started with the steps.

Step number 1 - we collect the necessary materials and tools

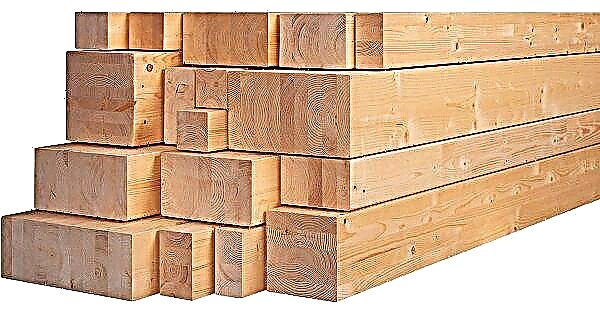

So, so that we can make the legs for the table in the simplest way, we need to take the following materials:

- bars with parameters of 5 by 10 centimeters,

- 60 mm screws

- special glue

- wood type filler.

For the manufacture of sturdy legs, we need quality material

As for the tools with which we will carry out the work, we will need to choose:

- clamps

- drill with a set of drills,

- saw

- clamp for the saw, allowing you to set its slope,

- Coarse and soft grit sandpaper.

Step number 2 - cut the bars to the length we need

To begin with, we will determine what height our legs will have. In each case, this parameter will be individual.Do not forget that there will also be a countertop above the legs, therefore, the table will end higher than the supports.

It is necessary to cut the blanks into parts of the size we need

So, take the bars of the size we need, and cut them into 8 segments of equal height. The fact is that we will be composing our legs piece by piece at once of two such blanks.

Step number 3 - glue parts to each other

So, we got 8 parts. Now you need to alternately take four of them, and apply glue to one of the planes of the timber, laying it in tight strips.

Carefully apply glue to the entire surface to be treated.

After everything is ready, it will be necessary to impose the planes of the dry bars on the side of the parts smeared with glue, and then press it to:

- to increase the degree of penetration of the adhesive into the structure of wood fibers,

- fasten the bars so that they do not slip.

After the bars will need to be placed in the clamps and tighten, and then leave until the glue is completely dry.

Clamp the workpiece in a vice so that it literally rests on the sides of the parts

Step number 4 - prepare the part for processing on a table saw

Now we need to prepare the fastened future leg for processing on a table-type saw. To do this, we do the following:

- drill holes for screws in the surface of parts,

- insert into the fasteners (screws),

- we fill the holes with filler.

Make concealable bar mounts

After the holes are ready, the details will need to be thoroughly sanded, however, do not try to perfectly smooth the roughness, this is not the final grout.

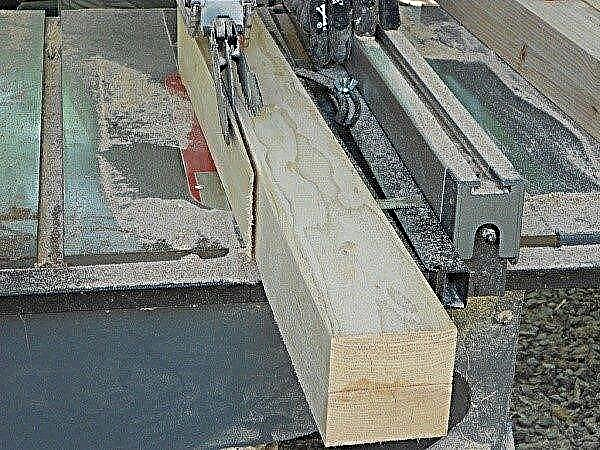

Step number 5 - working on a table saw

So, now let's cut the details. So, you need to raise the blade of the table saw as much as possible, and put a block under it so that about 8 centimeters are cut off from the edge.

At first, only one side will need to be sawed. Work should be done carefully so as not to spoil the prepared part.

Our task is to achieve alignment of the sides of the part

Then the parallel emphasis of the tool will need to be put at 7.5 centimeters, and remove a piece of the workpiece on the other side of the part.

Keep grinding the bars

If necessary, shape the parts into a cone shape

To make the legs cone-shaped, it is necessary to use the clamp for our saw, which was prepared at the very beginning, in the sawing process. To do this, put it under the bevel you need and cut the parts.

Use the lock to set the desired angle.

To summarize

Table legs are a functional device that determines the quality of the whole piece of furniture that you use for eating, working or other needs. Treat their selection and creation carefully, then you can enjoy the fruit of your labors for many years.

Not a single apartment can do without a dining table, and even modern bar counters cannot completely replace this traditional attribute. Install it in kitchens or in dining rooms, the size and materials of manufacture depend on the desires and financial capabilities of consumers. How to make a dining table with your own hands? Read in a special article.

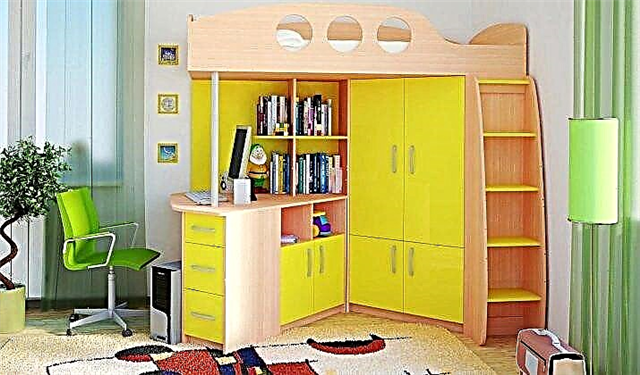

In children's rooms to create a warm and cozy atmosphere, parents prefer to set tables with multi-colored legs in bright colors, for example:

Legs can be any, the main thing is that they fulfill their functions and you like

As you can see, it would seem that simple details from a full-fledged piece of furniture can seriously diversify and dilute the atmosphere in the room.

Varieties

Supports for the dining table can have 1, 2, 3 or 4 legs. A single base should have optimal dimensions to give stability to the countertop and to ensure the safety of the entire structure as a whole. Options with 2 supports allow you to conveniently place your legs at the dining table. This is a good solution for kitchens decorated in modern styles.

3-leg solutions perfect for square, circle or triangle worktops. Three legs can withstand both small and large structures. 4 pillars are the traditional foundation. This option is considered the most convenient and reliable. On it you can place a countertop of any shape and size.

The basis for the kitchen table is of several types.

- Traditional. Such legs do not have the ability to adjust the height. These are the most uncomplicated models that are distinguished by simplicity of design, straight lines and financial affordability.

- Telescopic. These options have a special mechanism, thanks to which you can change the height of the tabletop.

- Design. Such decisions can not be found in the free market. Most often they are made to order according to individual sketches.

Depending on the model, the supports are square, round, rectangular, straight or curved. The assortment is large, so every housewife will be able to easily choose the optimal legs for any countertop and interior style.

Glass

Glass substrates are usually chosen for low mounted countertops. Tempered glass has the strength and reliability. Depending on personal preferences and countertop design, You can choose matte, transparent, mirrored or colored legs.

Selection rules

When looking for tabletop stands, it is important to consider the design features of these two components and their style. For example, for a round countertop, 1 massive support is best. A single underframe can be round or square, have sections along the entire length. Besides, it is necessary to consider the dimensions. For large tables, appropriate legs will be required so that they can withstand heavy loads.

The substrates should be chosen in accordance with the design in which the interior of the kitchen is decorated. For classic styles, traditional wooden models are suitable. They harmoniously fit into the space, add charm and elegance to the table. For minimalism and hi-tech chrome or plastic legs will do.

If the table in the future is often planned to be moved from one place to another, It is recommended to pay attention to the support with rollers. If mobility is the main criterion, you can take a closer look at folding stands. If it is necessary to ensure maximum stability and security of a bulky structure, the choice should be stopped on heavy legs made of metal (iron, steel, cast iron) or stone.

Not in the last place is the quality of products. Not only external impeccability, but also the life of the legs will depend on it. Wooden structures must be carefully sanded and coated with varnish or other protective agents. Glass products should not be chipped, cracked or scuffed. The quality of metal substrates is checked for evenness and smoothness of welded joints.

You will learn how to strengthen the legs of the kitchen table if they stagger from the video below.