If necessary, to repair cracks, bonding a certain kind of materials or sealing them use compounds called sealants. The highest reliability among all types of sealants are materials based on polyurethane. We will talk about the features of the application and the technology of applying polyurethane sealant further.

Polyurethane sealant - general characteristics and features

Sealants based on polyurethane are popular for gluing wooden, concrete, metal, plastic or brick products. In the process of use, they perform two functions: sealant and glue. After the polyurethane hardens, the surfaces adhere securely to each other. In addition, polyurethane is resistant to moisture, vibration or corrosion.

High humidity only improves the positive qualities of polyurethane. The composition of the polyurethane foam sealant contains polyurethane of a one-component structure. There are sealants with a two-component composition, they have improved sealing properties. The elasticity of such sealants is 99.9%. They are compared with polyurethane foam, since the quality characteristics of these two compounds are identical.

Polyurethane sealant is similar to polyurethane foam in the process of solidification, because a few seconds after application, it polymerizes and becomes solid. It is the increased humidity that promotes polymerization. Note that the polyurethane-based sealant hardens very quickly, so there should be no errors when applying it.

The sealant should be stored in a place protected from children, since its contact with the skin is unacceptable. It is forbidden to store polyurethane sealant in a room with too high air temperature.

Providing normal storage conditions for the sealant, it will serve in the open state for about ten months.

Among the advantages of using polyurethane sealant should be highlighted:

- highest level of elasticity

- good adhesion to metal, ceramic, brick, concrete, plastic surfaces,

- high level of self-adhesion,

- resistance to moisture,

- quick drying and hardening time,

- resistance to low temperatures over -50 degrees,

- the possibility of applying in the winter,

- resistance to ultraviolet radiation,

- complete lack of shrinkage,

- safety for health is ensured by the absence of toxic substances in the sealant,

- duration of operation

- the possibility of coloring, thus, the sealant also performs the function of paint.

Among the disadvantages of polyurethane sealants, only their instability to high temperatures, which reach more than +100 degrees, is distinguished.

Scope of use of polyurethane joint sealant

Since polyurethane sealant has a lot of advantages, the scope of its application is quite wide. It is able to close joints of an interpanel or deformation nature, seals the roof, is applied between the joints of logs or double-glazed windows, and is suitable for sealing joints between reinforced concrete slabs.

Polyurethane sealant is excellently manifested in the process of sealing joints between materials of various origins, with different physical properties and composition.

This material is economical in consumption. For example, if you want to close a seam with a depth of 10 mm, then only one meter of sealant will be required per meter of this seam.

Choosing a polyurethane sealant for the home, you should consider its main property - hardness. It is she who helps him withstand deformation and shrinkage.

If the hardness value for the sealant is fifteen units, then it is used in the process of sealing joints between panels, roof joints, various angles and joints. This sealant perfectly glues metal, concrete, wood and plastic parts.

If there is a hardness of twenty-five units, the sealant is used to seal joints that are constantly exposed to moisture. A value of 40 units implies the use of a sealant to work with glass surfaces, in addition, it allows you to seal the temperature joints in reinforced concrete structures.

The hardness of the polyurethane sealant of 50 units allows it to be used in the process of working with metal. The maximum hardness level is 60 units. Such sealants are used in the automotive or shipbuilding industries.

The scope of use of polyurethane sealant extends to:

1. Window and door structures, joints between panels on the facade of the building. After the packaging with sealant opens, it is immediately applied for its intended purpose. It is applied to the seam itself, the thickness of the application should not exceed more than half one centimeter. Thus, it will be possible to obtain reliable sealing of the coating and economical consumption of material.

2. In addition, the use of polyurethane sealant is associated with the processing of products based on natural stone. It is with the help of this material that almost imperceptible and neat joints are obtained. Due to the fact that the material is produced in various colors, it is possible to choose a shade that is as close as possible to the color of the stone. The use of silicone sealant, in this case, is unacceptable, since under its influence the stone loses its color and gradually collapses.

3. In places with increased vibration, a polyurethane-based sealant is also used. Since it is not prone to a change in shape or to shrink. It is used in the automotive industry to process joints in metal structures, due to its quick drying and joint strength.

4. When processing joints that are exposed to high or low temperature, a polyurethane-based sealant is also used. Its popularity is due to the excessive elasticity of the material and its resistance to punctures, destruction and abrasion.

5. When carrying out waterproofing work on the roof, in a pond or fountain. After processing, the polyurethane layer is sufficiently dense and resistant to moisture.

Appearance story

In the first half of the 20th century, the question arose - “How to replace natural materials such as cork and rubber?” What was needed was a cheap alternative, such material in the production of which non-exhaustible resources would be used. The first experiments were conducted in the USA - they studied the synthesis of polyamides. Germans went further than Americans by synthesizing polyurethane elastomers by the interaction of diisocyanates and polyols. As a result of numerous tests and experiments, elastic, semi-rigid, rigid and polyurethane foams were obtained. In the construction industry, flexible single-component polyurethanes (they are also sealants) and polyurethane foam are most widely used. In the European and American sealing markets, polyurethane sealants occupy a much larger part compared to silicone and thiokol based materials.

Benefits

- Elasticity. The flexibility of the polymerized material allows the use of polyurethane sealants to seal joints of dissimilar materials that differ in structure and coefficient of thermal expansion. Elastic joints remain leakproof even with fairly significant mutual displacements of the connected roof elements.

- Reliability. Polyurethane joints are highly durable. They are resistant to vibrations and deformations and can withstand heavy loads. The wide temperature range in which the material retains its characteristics allows the use of polyurethane-based insulation materials at temperatures from -55 ° C to + 80 ° C.

- Chemical and biological resistance. Polyurethane adhesive-sealant is a material that is not afraid of water, microorganisms and slightly aggressive substances. Even with continuous use in aggressive environments, it remains 100% water and gas impermeable.

The properties

- Elasticity up to 1000%

- Excellent adhesion to materials such as concrete, brick, wood, metal, glass

- Excellent self-adhesion

- Water resistance

- UV resistance

- Durability

- Frost resistance from -60 ° C to 80 ° C and the ability to work at temperatures up to -10 ° C

- Does not drain from vertical surfaces with a thickness of up to 1 cm

- Zero polymerization shrinkage

- After polymerization does not emit any harmful substances and can be used in residential premises

- Cured by humidity

Disadvantages

- Polyurethane sealants do not withstand constant exposure to high temperatures (above 120 ° C)

- It is not recommended to apply to substrates with a moisture content of more than 10%. Adhesion to some plastics is not high enough to ensure a reliable bond. For use in conditions of high humidity of the base and increase adhesion, there are special primers

- A complex and expensive process for the disposal of polymerized material

Areas of use

- Interpanel seams - in industrial and civil engineering.

- Concrete floors - sealing of expansion joints.

- Sealing of any joints on the roof - pipes, ridge, parapets, gutter.

- Structural glazing, greenhouses and conservatories.

- Automotive industry - gluing windows, sealing joints in refrigerators and vans.

- Wooden house-building - a joint between logs.

- Installation of windows - to protect the mounting foam from ultraviolet radiation.

- Double-glazed window production

- Shipbuilding - joints in decking, joining structures.

- Airfields and bridges - joints between reinforced concrete slabs.

Application technology

Due to the fact that the sealant is one-component, does not contain solvent, polymerizes within 20-40 minutes, it is produced in a packing of 600 ml (foil tubes) and 310 ml (metal cartridges). For application, a special construction gun is used. There are guns

- Mechanical (for a small amount of work, private use)

- Pneumatic (for medium and large volumes of work, professional use)

- Rechargeable

Before starting work, the nozzle is screwed onto the gun and cut to the desired diameter, depending on the width of the seam. For the best quality seam, it is recommended to apply sealant so that the width of the seam is approximately 2 times greater than the depth.

The same stuff

At the same time, the joints are glued and sealed. Distinctive properties of polyurethane sealant are: high elasticity and high adhesion to the surface (adhesion) of most materials used in construction. They have good adhesion to brick, concrete, stone, wood, metal and many polymers. As a rule, polyurethane sealants are not afraid of water and low temperatures, resistant to mechanical stress and damage, as well as a number of chemical influences. But most importantly, polyurethane sealants are easy to use. All this reduces the cost of construction.

The main share of polyurethanes used includes those narrow areas of construction work where other sealants simply can not cope. This is sealing the expansion joints of building structures, industrial floors, other joints of various buildings and structures (joints in monolithic construction, in panel house building, during the installation of metal structures).

As glue, polyurethane adhesive sealants are used for gluing facade and interior decoration elements, thermal insulation, roofing materials, etc. In decoration, they are used as universal glue when laying ceramic tiles on any base: brickwork, concrete, drywall, metal, wooden floor, etc. Filling small gaps can be completely invisible, therefore, does not require additional decorative refinement. If necessary, the seam can be painted with any paintwork composition.

Polyurethane sealants are extremely flexible and able to stretch without tearing, taking their original shape after unloading. For most of these sealants, the normal operating mode is a multiple elongation of 2 times or more. However, quite often it is important not so much the magnitude of the elongation as the ability to successfully resist the destructive force. This can be a deformation caused by a large mass of structures, strong wind loads, high water pressure. Polyurethanes easily tolerate multiple compressions / stretches, which largely depends on tensile strength. This property of the sealant is used in structures that are subject to significant mechanical stress.

The seams do not crack, and if necessary, are easy to repair. Due to the fact that the sealant based on polyurethane has self-adhesion, it can be applied on top of the old layer, without first removing it. Excellent adhesion appears to other sealants. This means that if any seam is damaged, the repair of the defective area can be done with polyurethane. For example, silicone in relation to itself does not have adhesion, so any repair of the seam comes down to a complete cleaning of the surfaces. Which is difficult and expensive.

Work with polyurethane sealant

The one-component polyurethane sealant is ready to use from the start. Polymerization occurs under the influence of air humidity. The polymerization rate of polyurethane sealants is about 2-3 mm per day. That is why the commissioning of especially wide joints (more than 20 mm) is carried out carefully, controlling the degree of polymerization. The two-component sealant consists of a base compound and a hardener, which are mixed before use. The advantages of a two-component include higher adhesion and increased resistance to moisture. It is recommended to apply sealant at temperatures up to + 5 ° C, sometimes work can be performed even at low sub-zero temperatures.

Apply sealant using a closed tubular gun. Polyurethane sealants must be applied in a clean, dry joint. Before starting work, the surface is cleaned and degreased, and the work itself is carried out in well-ventilated areas. If this is a seam in concrete floors, then the concrete should be mature, that is, have a shutter speed of at least 28 days. When performing critical work, in order to increase the adhesion of the sealant to concrete, wood or metal and to increase the life of the contact point, it is advisable to use special primers. The time period for the formation of the film is from 30 to 90 minutes, depending on the modification, each of which has its own curing speed. After polymerization, the polyurethane sealant can be painted.

After filling the cavity, a neat rubber-like seam is formed, which has a high density and resistance to deformation and aggressive external environment, maintaining its properties for a long time. Curiously, the material demonstrates adhesion to 100% of the surface, regardless of its texture.The standard recommended operating temperature range for the polymerized joint is from -40 ° C to + 80 ° C, however, in fact, polyurethane sealants have a resistance from -60 ° C to + 120 ° C. It should be noted that polyurethanes do not withstand the constant effects of excessively high temperatures.

What is characteristic, polyurethane sealants against the background of other similar materials are distinguished by their efficiency. They are characterized by a lower coefficient of consumption than silicone or acrylic compounds, and the elasticity of polyurethanes is sometimes higher by an order of magnitude (up to 1000%). Moreover, shrinkage during setting and curing is absent, while for other sealants it can be up to 20%. To top it off, polyurethane sealants have the longest life. For external structures, it is from 15 to 55 years, for internal from 25 to 70 years. Silicone sealants in similar conditions last 1-3 years and 10-20 years, respectively. For acrylic compositions, the durability index is from 5 to 10 years.

And although polyurethane sealants against the background of rivals sometimes lose in price, many professionals give preference to them. Due to the versatility of the material, simplicity and manufacturability of the application, reasonable costs with a high result, the use of polyurethane sealants is becoming widespread.

One component

This substance consists of polyester compounds and hardeners. After application to the adhesive surface and in contact with air, it hardens, after which it forms a durable surface. Often, these adhesives require additional moisture, so the surface is sprayed with water. An hour later, the sealant forms a strong surface film, the process of complete solidification is about a day. If the temperature drops below 23 degrees, the pour time increases, respectively, with a rise in temperature it decreases.

The sealant is convenient to use, it adheres well to brick, concrete, stone, metal and wooden surfaces. It is quite resistant to ultraviolet and precipitation. Most often, such adhesives are used in individual construction and households.

Two-component

This sealant also consists of polyester resins and hardeners, which are mixed before starting work. The quality of mixing the sealant fully affects the properties of the adhesive, as well as the time it hardens. Typically, the compositions are mixed at room temperature, since low temperatures increase the viscosity of the substance, which greatly complicates the qualitative mixing of the composition. The sealant has good adhesion and water resistance. This tool is well combined with all kinds of surfaces, it is often used when gluing sheets of metal and glass.

Scope of polyurethane sealant

Due to their resistance to ultraviolet, frost and water resistance, these substances are great for closing window and door openings located in concrete, brick, stone and wooden walls, all kinds of metal structures, as well as for sealing block, panel and other facades. The tool is easily applied with a gun or a conventional spatula, in the end, a beautiful, strong and wear-resistant seam is obtained, which can then be painted in any color.

The sealant adheres remarkably to marble, granite, sandstone, quartzite. In addition, it creates a subtle and aesthetic seam. Often it is used to close up cracks and joints formed in the floor. The sealant forms a sturdy, reliable, resistant to stress and abrasion seam surface, which is quite resistant to chemicals.

Polyurethane sealant is indispensable in such an area of construction as waterproofing work. Good resistance to moisture allows you to create a strong monolithic layer resembling a rubber surface. Such an adhesive is indispensable in mechanical engineering when bonding individual parts or their constituent parts. Production of commercial equipment is also impossible without the use of polyurethane sealant. Modern manufacture of sandwich panels, metal-plastic windows, installation of window sills, pipe insulation also requires the use of such an adhesive. Often, this sealant is used to glue tiles on almost any surface.

Bonding technology

There are three methods that help secure materials, parts, or their elements.

- The cold method involves applying glue to a completely clean, fat-free surface. After lubrication with the product, the material or part is left calm for ten minutes, after which a second layer is applied and the adhesive surfaces are pressed.

- During hot bonding, the adhesive applied to the product or surface is kept for half an hour, and then it is heated to +80 degrees, after which the surfaces are squeezed using a press.

- The wet adhesion of the surfaces involves spraying the adhesive parts with water, followed by pressing.

Comparison of polyurethane sealant with other compounds

Among the main types of sealants, compositions are distinguished for:

- silicone based

- polyurethane based

- acrylic based

- bitumen based.

We will talk about their features further. The choice of this or that type of sealant depends on the individual characteristics of the material to be glued, also the processing location and the effect of external stimuli in the form of high or low temperature, high or constant humidity, vibration, mechanical stress, etc. are also important factors.

The main and quality determining property for each of the sealants is its elasticity. In addition, a good sealant reliably holds the joints, under the influence of any irritants.

1. Acrylic-based sealant - they are characterized by the highest elasticity, but at the same time they are poorly kept in shape and prone to deformation. Suitable for indoor use. They are used in the process of installing windows and doors, in addition, they are used to seal cracks in the ceiling or walls. There are two options for these sealants:

- moisture resistant compounds

- non-moisture resistant sealants.

The first option is used in places with high humidity, and the second, when gluing furniture. The acrylic sealant lays well on the paint, so it is almost invisible at the installation site.

2. Silicone based sealants - are unstable before exposure to paints and varnishes, therefore they have their own color palette. They are characterized by higher moisture resistance than acrylic and very well tolerate high and low temperatures. There are two types of silicone sealants:

The first option is used in the process of working with metal products, as it is not able to enter into various kinds of reactions with it. In addition, it seals the joints between the tiles in places of high humidity, such as swimming pools, bathrooms. The second option is suitable for wood, plastic and ceramic products. It is by no means suitable for processing products made of metal, since the surface will rust over time.

The only drawback of silicone-based sealants is the presence of an unpleasant odor that is released when working with them.

3. Polyurethane adhesive sealant has the highest strength and reliability. It has increased elasticity, is resistant to deformation, and is widespread when working outdoors, as it tolerates changes in temperature, moisture, ultraviolet radiation, etc. In addition, this type of sealant tolerates painting and varnishing.

Allocate another variety of sealants, which are called facade. These include materials that are best suited for work on the facade of the building. The best option for facade processing is a polyurethane-based sealant. Since, when compared with silicone or acrylic sealants, it is characterized by higher strength before shrinkage, deformation and mechanical damage.

Compositions of silicone and thiol type are competed with a polyurethane-based sealant. Since they, in comparison with polyurethane sealant, have slightly less elasticity and adhesion. Polyurethane sealant has more significant advantages than these compounds. It does not require preliminary surface preparation for its application, unlike silicone sealant. It is painted, and silicone sealant is available in a finished color, which is sometimes difficult to match the color of the surface.

Thiokol sealant has a shorter period of use, unlike polyurethane, it requires periodic renewal of joints. Therefore, despite the fact that the price of polyurethane sealant is slightly higher than that of silicone and other compounds, it surpasses them in many respects.

In order to buy polyurethane sealant, you should contact any construction supermarket or store.

Instructions for applying polyurethane sealant

Due to the presence of only one main component in the material and due to the absence of solvents in it, it is produced packaged in 600 ml foil tubes and 310 ml in metal cartridges. In order to carry out the application of sealant, a special gun is required. There are three main types of devices for applying sealants:

- mechanical type pistols - designed to work in private construction, as they help to carry out a small amount of work,

- pneumatic-type pistols allow medium-sized work to be performed, used by professionals,

- pistols with a battery are used in multi-story construction.

Before starting work on the gun set the nozzle, and the seam is cut to the required length.

To ensure the high quality of the work performed, the diameter of the seam on the sealant should be twice as large as the depth of the seam on which it is applied.

Before applying polyurethane sealant, dust, dirt, paint or various types of oil are removed from the surface.

It is not recommended to use sealant in the open air during precipitation. If rust is present on steel surfaces, they are cleaned by grinding. Thus, it will be possible to increase the adhesion of the sealant several times, with the surface on which it is applied.

Seams of interpanel or interblock type are pre-insulated with foamed polyethylene or polyurethane foam. The sealant is applied on top of the insulation coating; for this, a manual air gun or spatula is used. Try to apply the material evenly so that tears or voids do not form. To level the applied sealant, use steel or wooden lining. The surface should become L-shaped. After three hours after applying the composition, it becomes resistant to moisture, frost, atmospheric influences. Until this time, the material should not be affected by these irritants.

Features of sealants

Distinctive features of sealants are the following qualities:

- The increased elasticity of the composition. This property contributes to the reliable adhesion of the polymer with materials having different properties. Under various mechanical influences, which are exposed to joints with a sealant applied to them, they are able to remain airtight and maintain their functions.

- Good adhesion to most types of building materials. The composition is well fixed on concrete, wooden surfaces, metal. In addition, the sealant will adhere to the previously applied similar composition.

- Increased resistance to wear. No problems with high humidity and prolonged exposure to direct sunlight. This distinguishes polyurethane sealant from other binders.

- Sufficiently long fixation of fastened materials. Achieved thanks to the unique formula of the composition of the binder.

- Polyurethane sealant copes well with the temperature differences characteristic of the climatic conditions of our country. Work is possible both in the Far North and in the southernmost regions of our country, since the composition does not lose its characteristics at temperatures from -60 * С to + 40 * С.

- In the process of applying to the surface of the material, smudges and stains of the sealant are excluded. This greatly facilitates the work of the installer and reduces the complexity of the operation. The rule is observed with a thickness of the applied layer up to 10 mm. In addition, the shrinkage of the sealant after hardening is minimal.

- The speed of polymerization of the composition to the end point.

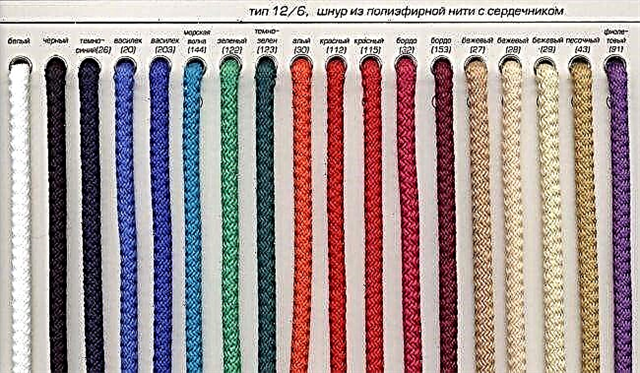

- A variety of color palette of materials. The manufacturer offers almost the entire main color palette for every taste of the buyer.

- Environmentally friendly sealant. With prolonged exposure to ultraviolet and high temperatures, the sealant does not emit hazardous and toxic substances into the environment. This important property makes it possible to use it in the arrangement of residential premises.

- The sealant is a fairly durable material, so mechanical damage is not afraid of him.

Concrete sealants

Used in work with concrete surfaces. When performing work outdoors, the sealant can be immediately used without wasting time on preparing the working surface of the material. The sealant is effective in filling cracks in concrete (expansion joints), which appeared under the influence of uneven loads on the structure.

Roofing sealants

The composition of this sealant differs from the above by the presence of resin. The resin is made under special conditions, due to which the required viscosity of the material is achieved. Use this sealant to seal the seams of flat roofs. It is divided into two types: sealing and waterproofing. The first requires a dry base for operation, the second is used to protect structures from moisture. Also for sealing roofs, the following compounds are used:

The most popular is silicone sealant. The basis is iloxane rubber. This substance gives the composition resistance to moisture, excellent adhesion to most building materials. In addition to these qualities, the sealant withstands prolonged heating by the rays of the sun, without losing its properties, which makes it possible to use it on roofs made from natural tiles.

Sealant Safety Tips

When working with polymeric material, as with any composition, safety and precautionary measures should be observed:

- Sealant stains and smudges can only be removed with a solvent. White spirit, as well as gasoline, can act as a solvent. Work should only be done with safety glasses and gloves. If necessary, wear a respirator to protect your respiratory system.

- Sealants that are intended for outdoor use should never be used for indoor use, due to their toxic emissions.

- After applying the sealing layer, the master has only twenty minutes left, after which the polymer sets completely and cannot be processed.

Rules for working with sealing compounds

A number of simple rules should be followed when working with sealant. Here they are:

- Before performing work, it is required to clean the work surface from contaminants.

- To work with panel seams, it is necessary to use one- or two-component polyurethane sealants that can withstand deforming effects, up to 10-12%.

- It is necessary to look at the proportions of the main and hardening pastes for their mixing, if a two-component sealant is used, in the passport, which is supplied with the batch of the produced material.

- The preparation of the sealing composition is carried out in certain portions. The mixing process must be carried out with an IE-1035 power tool, with a nozzle for mixing. Stir for ten minutes until a homogeneous consistency is obtained.

It is forbidden to violate the following rules:

- To retreat from the dosage of components that is written in the product passport.

- Try to manually mix the composition.

- Additionally dilute with various solvents.

- The temperature of the sealant should be monitored, which should be fifteen degrees above zero, regardless of the ambient temperature. At low temperatures, uniform heating of the mixture should be made.

Joint sealing operations should be monitored by the construction laboratory, as well as by the technical personnel of the construction site. Also, the laboratory is obliged to check the quality of incoming materials for compliance with their technical conditions. The following parameters should be checked:

- The degree of preparation of the edges of the joints and joints before applying the sealant.

- The temperature of the sealant itself.

- The uniformity of the application of sealant on the material.

Despite the apparent simplicity, the process of sealing various structural elements is very complicated. In the process, you must clearly follow the instructions, since the reliability of the design or product, its performance as a whole, depends on the quality of the work performed.