Simple recommendations will help you correctly perform plastering work with perlite composition:

- When mixing the solution, the rotation speed of the mixer or mixer nozzle should be no more than 600 rpm.

- Preparation of the base should be done carefully. The adhesion of the coating and the base, durability, strength, and appearance depend on its quality.

- So that the solution does not turn out to be too liquid, the entire recommended amount of water should not be added. Water is added a little after perlite begins to give it away.

- One of the mistakes is the monolithic plastering of expansion joints - the coating should be done with a seam repeating its geometry. The joint itself in the plaster coating is subsequently filled with sealant with a polyurethane base.

- To keep the proportions of the components, in the batch use the entire volume of the SS from the package.

Additional information about the material in the video:

To preserve heat in the house, reduce the load on the walls and foundation, perlite plaster is widely used. The eco-friendly composition of natural materials does not require special skills, even a layman can finish it.

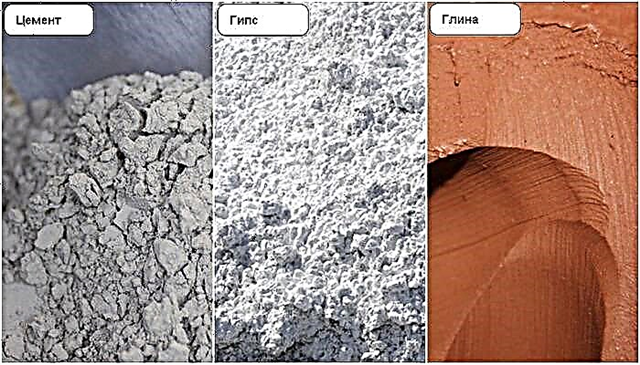

Types of binders and fillers

As a binder, use:

- cement, which provides after hardening of the plaster mixture an increased margin of safety. Curing of the composition, including cement, begins 15–20 minutes after the introduction of water and lasts 10–12 hours. Operational hardness and performance are acquired after the final completion of the hydration process, which lasts 28 days. For plastering, four hundredth Portland cement or cement with the marking M500 is used. Use fresh binder. Cement loses its properties and cakes during prolonged storage in wet conditions,

- clay, which is a fairly common natural material. Clay-based stucco has been used for centuries to decorate the external walls of wooden buildings, as well as for interior work. Due to the ability of building materials to withstand elevated temperatures, it is used for decorating fireplaces and stoves, and its increased resistance to moisture allows reliable protection of adobe structures and wooden structures from the outside. Due to the low cost and ease of use, clay-based working mixtures are widely used in finishing activities,

- gypsum, added to the lime composition as a special additive. It is a powdery substance that reduces the setting time. If it is necessary to provide accelerated hardening, then using gypsum, the setting time can be reduced to five minutes after diluting the working mixture with water. The final solidification occurs within half an hour. Gypsum powder reduces the settlement of the plaster after hardening, and also increases its strength properties,

- lime. A feature of the material that is used only after extinction is a set of hardness in contact with air. Slaked building material used in plastering, unlike quicklime, is not subject to cracking. Extinguish lime using pits or containers. The technology involves the use of an accelerated option of extinguishing or slow for a month. Compositions including lime are distinguished by bactericidal properties, ductility and reduced price. They have improved adhesion to various surfaces, including wood.

Along with astringent components, various fillers are used:

Types of plastering compounds

Proportions of mortar for wall plaster

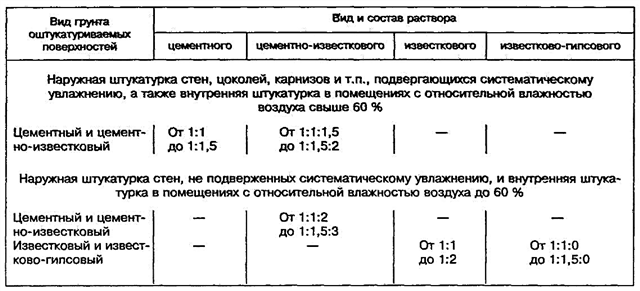

When choosing a composition for plastering, it is necessary to take into account a number of factors:

- binder used

- surface material

- temperature conditions

- humidity level.

Choosing the best option for plastering material, pay attention to the following points:

- plasters containing building lime and cement are used for facade decoration when it is necessary to provide protection from the negative effects of high humidity. If increased humidity is expected in the interior, this composition is also used for interior decoration,

- the introduction of clay, slaked lime and gypsum into the plaster composition allows you to use it with an increased concentration of moisture in the air. Such mixtures are mainly used for plastering dry heated and unheated rooms located inside the building,

- cement-gypsum plaster composition, in which clay is added, is used for interior decoration with normal moisture concentration. It is possible to use these binders for plastering the facade surfaces of buildings operated in dry climates.

Consider these recommendations when choosing a plaster composition.

Features

Plaster mortar is a wide range of mixtures. The spectrum includes various compounds, this is due to the purpose of each material. The basis of any raw material is an astringent. In addition to it, manufacturers include various additives. This is a pasty mass. It is spread on the walls or ceiling, stretching until an even layer is formed.

The composition of each mixture directly affects its purpose. For this reason, mixtures may be intended for indoor or outdoor use. Some formulations are relatively versatile and designed to work indoors as well as outdoors. A distinctive feature of these mixtures is their resistance to adverse environmental factors. One of the features of plaster compositions is the granularity.

It is the size of the fraction that indicates whether the composition is the final or starting one. Often, a rough texture is used to prepare the base for the finish. Depending on this, one or two plasters are used on the same surface. In this case, one of them is the preparation of the basis for applying the other. Due to the particle size and the additional effect, the cost of the topcoat is always greater than the starting analogue.

Sometimes the plaster mix is confused with the term “dry plaster”, which is usually understood as plasterboard sheets.

In the first case, it is a binder and fillers in a balanced formula. They must be kneaded before applying the plaster material on the prepared base. The second variety is noteworthy in that it does not need to be adjusted before use on the surface.

Such material may have a different shade. It depends on the components of the mixture.

- In one case, it is a gray concrete color, in others it is dirty beige, sometimes milky.

- White is considered to be basic.

- The creamy-based finished material may be colored. However, the range of shades of such mixtures is scarce. This makes it possible to paint the stucco mixture yourself.

All solutions are divided into fatty, skinny and normal. Mixtures of two or more components are called complex. In fatty varieties, an astringent component predominates. Therefore, they shrink and crack, require reprocessing.

It is impossible to prepare a plaster composition without an idea of the varieties of such mixtures. In the modern construction market, a wide range of similar products in various forms of release is offered to the attention of the buyer. It is different in volume and composition.

There are several popular mixtures:

- cement-sand,

- cement-lime,

- gypsum

- clay

- glue

- polymer

- specialized.

Cement-sand options - ordinary cement mortars and masonry mixtures with high resistance to mechanical stress. In the process of drying, they sit down, are applicable in heated and unheated rooms. Cement-lime mixtures are characterized by the presence of fine sand in the composition. Suitable for indoor use, have antibacterial properties.

Clay varieties are environmentally friendly. They contain asbestos, lime and cement. Less durable compared to cementitious compounds. Gypsum plaster mixes are used more often as levelers. These compounds are hygroscopic, not suitable for finishing rooms with a high degree of humidity. With frequent contact with water, they wear and deteriorate.

Adhesive plaster mixes are needed to fix the insulation or waterproofing. Most often, such products are used when leveling surfaces in work with the mesh. Polymer plasters do not have sufficient ventilation, however, they have high fire resistance and sound insulation. They are made on the basis of acrylic, silicone. There are silicate varieties.

How to do it yourself?

It is worth remembering that first you need to carry out preparatory work:

- Assess the surface to be leveled.

- Dismantle the old finish (remove, knock down or cut the plaster).

It is especially important to ensure a solid base and the absence of crumbling sections on the wall. After removing old wallpaper and plaster, the surface is primed

Such a base should dry for at least 10-12 hours.

For leveling, plasters based on gypsum or cement are used. Gypsum plaster creates an optimal microclimate in the room, but is afraid of moisture. Therefore, such material is used for "dry" rooms - living rooms, bedrooms. Cement composition is used in rooms with high humidity - toilets, kitchens, bathrooms.

It is better to level the brickwork with a mixture based on cement. It is allowed to apply a layer with a thickness of up to 2 centimeters, with a larger thickness, a grid for plaster is used. The gypsum base is suitable for leveling concrete walls.

Gypsum material

Consider a step-by-step instruction on how to align walls with gypsum plaster:

- Mix the mixture with water, having previously read the time and intensity of mixing on the label.

- The resulting mixture is applied "casting" on the wall with a spatula. Then firmly press the spatula against the wall and rub the solution, remove excess.

- Sand the surface using sandpaper.

No beacons

Leveling walls without beacons to level walls with plaster has a number of advantages.

The number of materials used in the work is significantly reduced (how to calculate the amount of plaster for different types of mixtures?). When installing beacons, the minimum layer of stucco is 7 mm, and inexperienced owners apply much more material. Application without beacons allows the application of plaster with a thin layer of 4 mm, which saves space.

With a plane difference of 1 - 1.5 cm, it is impossible to achieve a positive result in this way, even experienced craftsmen find it difficult to level the walls "by eye".

Despite the fact that the material consumption is less, this does not mean that the work will end faster. Conversely, performance without beacons is reduced even by professional finishers. And the cost is increasing. However, if independent work is planned that does not require high speed, then saving money will be significant.

After completing the preparatory work and preparing a special solution, you can proceed to leveling the surfaces. Three stages are distinguished in the work:

Spray - the first layer, which allows you to securely fix to the wall all other leveling layers. The main task at this stage is to completely cover the surface with the solution without leveling, this will be done in subsequent stages. For spraying prepare a mixture with a consistency of "thicker sour cream." The first layer is poured by a trowel or building bucket onto the wall with a sharp movement of the wrist.

With the correct execution of all actions, the plaster lays evenly and does not slip from the right place. If the mixture lays down "slides", then you need to attract a half-trick to work and slightly level the surface. The first rough coat can also be applied with the usual “spreading” with a spatula.

The next stage is the ground. It is necessary to start it after the first layer has completely dried, so that the fresh solution holds firmly. All flaws are filled with a stucco mixture, the surface is smoothed as much as possible with a trowel, and excesses are removed with it. The solution is not poured, but applied with a grater. At this stage, you must be very careful, not rush and carry out work in small areas.

After this procedure, the surface of the wall is leveled, however, there are stripes, flaws and small roughnesses on it. All this is eliminated at the third stage of work, which is called “grouting” or “smoothing”.

They begin the stage when the mixture has seized, crusty, but has not completely frozen. The third layer has a smaller thickness, it is applied to the wall with a bucket from top to bottom

The mixture is leveled and rubbed into the surface, these actions make the walls smooth.

Attention

After completion, the presence or absence of defects is assessed, for this a rule is applied to the walls.

Mix tips and tricks

A cement-sand mortar can be made by selecting and measuring the components yourself. It will cost much cheaper. And you can buy a ready-made dry mixture. When choosing, they are guided by the type of coating, operating conditions, base material, labor costs, cost.

Some selection rules:

- For the decoration of the exterior surfaces of buildings, the compositions of the central processing center and central office for facade work, or universal, are used.

- All types of DSPs and DSSs are suitable for rooms, but those that are designed specifically for indoor use are optimal.

- For rooms with high humidity use compositions without lime. For dry rooms, an CID may be preferable, since it creates the most favorable conditions.

- For work in the winter, mixtures with antifrosty additives are used.

- According to special requirements (to reduce noise, insulate walls, etc.), special compositions are used.

- For wooden surfaces, it is better to take a digital cylinder.

- The indicated maximum permissible layer thickness is taken into account if a high leveling coating is required. This indicator is associated with the duration of the work.

- Gypsum-containing walls as the basis for not all ready-made mixtures are “tough”.

- It is better to purchase mixtures of those manufacturers that have established themselves with high quality products.

“Correct” mixtures are packed in three-layer paper and film bags. They do not have the same release time (should differ by at least a second). It is better to purchase mixtures made recently.

Since there is a possibility of acquiring a fake, it is better to be safe, to purchase a couple of bags of the mixture, to test it in practice. If the setting time stated on the package is carried out experimentally, the plaster mixture has a normal consistency, and the coating has the desired surface quality, you can buy the remaining amount.

Tips & Tricks

Most homeowners prefer budget repairs, in which the bulk of the construction work is done on their own. Stucco walls are no exception to this.

This process is not difficult, but in order to do everything correctly, the following recommendations of experienced masters can help:

- Only those walls that have significant defects and bumps need to be stuccoed. This will help not only speed up repairs, but also save money on finishing.Therefore, at first the control of the surfaces is done, and if the lighting falls on them at an oblique angle, then alignment is done. It is also necessary to cover with the solution those walls on which it is planned to fix the baseboards.

- It is possible to provide good durability to the coating using a primer made from water and PVA glue.

- If the plaster is applied to brickwork, and the room temperature exceeds 23 ° C, then its base should be thoroughly moistened.

When aligning the walls, it is advisable to use beacons, they allow you to set the level correctly and determine the optimal thickness of the finish.

In the event that the base is single-layer, it must be immediately leveled after coating with a solution. You can also use special trowels for this, they are used after the coating has set with the surface

If the finish involves a second layer, it is important to wait until the solution of the first layer sets.

To make high-quality plastering of walls allow gypsum sheets. They are suitable in cases where it is necessary to level very large areas of the room, since continuous preparation of the solution can slow down the work.

The mixture hardens quickly and cannot be used afterwards.

Before the start of plastering, the working area is necessarily calculated and the level of all the differences and slopes is determined. Thanks to such calculations, you can pre-calculate the consumption of material, and make estimates.

Small and large cracks can appear after finishing, if the solution is poorly mixed or quickly dried under the influence of drafts. Therefore, the mixture should be thoroughly mixed and plastered only indoors. In addition, the surface must be well grinded, and if the mixture is applied in several layers, then a building mesh should be used.

Putty allows you to eliminate only minor irregularities, reaching 5 mm, since its layer can not exceed 5 cm. Therefore, if the walls have large differences, then it is best to hide them first under drywall, and then apply the mixture

It is also important to carry out calculations of the geometry of the room and make all angles 90 °, since unevenness and curvature will cause a mismatch of wallpaper and the formation of an incorrect slope above the cabinets.

Gypsum plaster should be purchased taking into account the climatic conditions in the room. If a constant temperature drop and high humidity are observed in it, then special types of the mixture must be preferred.

About plastering walls with gypsum, see the next video.

Preparation of concrete walls for plaster

The process of preparing interior walls of concrete for plaster consists of the following steps:

- The old coating is removed in the form of weak plaster, whitewash, paint (in which cases it is possible to apply plaster on old paint, we recommend reading here),

- Defects of concrete walls are determined. In the presence of sagging, they are cut off with a hammer and a chisel. Massive chips and deep shells are sealed with a cement-sand mortar with a ratio of 1: 3, if necessary, steel mesh is used for reinforcement,

- On smooth walls, notches are made using a hammer and a chisel, the maximum notch pitch is 10 cm,

- If necessary, a device for hidden wiring, performed strobes for wires,

- The surface of concrete is cleaned. A brush and water are used to remove dust and dirt. Wall treatment can be carried out using compressed air or a strong jet of water, which greatly accelerate the cleaning process,

- A primer is applied to the surface of the wall.

Notches on concrete wall

We will talk more about the types of primers for concrete walls later.

Primer for concrete walls before plastering

Priming concrete walls is necessary to:

- Reducing the absorption of water from the solution into the concrete base,

- Protecting the concrete wall from mold and mildew,

- Increasing the strength of the protective (surface) concrete layer,

- Dust removal of concrete surface. The primer binds the dust particles and makes the substrate clean,

- Improving the adhesion of the stucco with concrete base.

Priming on a concrete wall

Further we will consider how to prime concrete walls before plastering:

- For smooth concrete surfaces, concrete contact primers are ideal. After application, the composition fills the pores in the concrete, and a rough layer with high adhesion is formed on the surface, which contributes to good adhesion to future plaster. We recommend compositions of the following manufacturers: Feidel Betokontakt, Knauf Betokontakt, Prospectors Beton-Kontakt.

- Old concrete surfaces can be strengthened with a deep penetration primer designed specifically for impregnating fragile substrates. Such soil impregnates the top layer of concrete, thereby strengthening it and giving the necessary strength. From the manufacturers we recommend: Prospectors of Deep Penetration, AquaNova Nova, Optimist acrylic of Deep Penetration.

Primer Prospectors "Deep Penetration"

For the preparation of porous concrete surfaces (aerated concrete, foam concrete), primers are needed that reduce the absorption capacity of the base, thereby preventing uneven setting of the mortar. The following primers are perfect: Knauf Mittelgrund, Knauf Rotband Grund (for gypsum plasters), Ceresit CT 17, Toiler TR10.

When applying the primer to the base, be sure to follow the manufacturer's instructions. As a rule, the primer must be shaken before application, and the application process should be done in several layers.

Installation of beacons and reinforcing mesh

If the old wall has differences of more than 10 mm, then beacons must be installed before applying the plaster. Lighthouses are needed for smooth application of plaster with the same layer in thickness. As beacons, it is better to use metal profiles.

Lighthouses on a concrete wall

If a

the thickness of the planned plaster is more than 20 mm, it is additionally necessary

arrange a reinforcing mesh. Fastening the mesh to the wall using

dowel-nails.

Next, you need to prepare the solution in accordance with the manufacturer's instructions. To exclude the formation of lumps, water should be added to the dry mixture, and not vice versa.

Which plaster is better to plaster brick walls

Of the great variety of plaster compositions for leveling brick walls, the following are primarily chosen:

According to the functionality of the mixture are divided into:

- ordinary (leveling, filling volume),

- decorative (decorating the surface),

- special (sanitizing, X-ray, moisture-proof, soundproof, etc.).

By scope of application:

- mixtures for internal coatings,

- compositions for external walls (front),

- universal mixes.

Strength, vapor permeability, easy workability, service life and many other properties of solutions depend on the base - a binder. In terms of financial costs, mineral-based mixtures are cheaper and more affordable. And since for the plastering of bricks the volume of plastering is large, it is more rational to choose materials of this class for brick walls.

Suitable solutions for concrete and brick substrates are: gypsum, cement, lime, cement-lime (except gypsum-lime).

Cement-sand mixture cps

This is the case when the name speaks for itself. Cement is a binder that, when hardened, is converted into a durable artificial stone. The final strength of the coating depends on the type and brand of cement, moreover, the DSP in strength - the champions among mineral-based finishes.

- universal (applicable for indoor, outdoor, for rough, decorative finishes),

- moisture-, frost-resistant,

- durable

- maintainable

- green

- easily accessible (you can prepare the composition yourself),

- budget

- fireproof

- durable.

The disadvantages are the following:

- long set of strength (3-4 weeks),

- heavy weight

- unstable to vibrations, building upset,

- incompatible with wooden or smooth walls.

The usual composition of DSP contains cement (usually Portland cement) with sand in a volume ratio of 1: 3 to 1: 4. For mixing use clean, cold water. Functional additives are introduced to improve quality.

Calcareous

Natural material known since Roman times.

Application of lime plaster in the basement

- environmentally friendly

- easy to fit

- vapor permeable

- bactericidal

- fire resistant

- “Sticky, chain” to mineral substrates, as well as cardboard, wood, clay,

- durable

- maintainable

- universal.

- low water resistance

- cracks when vibro loads

- strength is gaining slowly

- when working, protective equipment is required,

- inferior in strength to other mineral plasters.

The binder successfully works in tandem with cement, gypsum, clay. Suitable for bathrooms, bathrooms, basements. Not suitable for facades at all.

Gypsum plaster

A special favorite of plasters when doing work indoors. But plastering the facade of the house does not allow the instability of gypsum to get wet. The only place on the street where plaster material is applicable is glazed loggias / balconies. However, formulations with additives have been developed that allow the use of gypsum outdoors, as well as in bathrooms. However, such materials are much higher in cost, so they are not used for roughing.

- fast set of strength

- high ductility

- environmental friendliness

- vapor permeability

- reliable adhesion

- low thermal conductivity

- fire resistance

- light weight

- does not crack when hardened,

- easy to sand

- it is easily restored

- durability.

- "rabies",

- life is too short

- not resistant to biodefeat,

- low frost resistance.

Perlite

Material refers to special types. Perlite filler - sand performs heat and noise insulation properties. The binder is most often cement.

- low weight coating

- low thermal conductivity

- environmental friendliness

- fire safety

- resistance to microorganisms and mold,

- vapor permeability

- durability.

- high dust generation

- some difficulty mixing.

You can reduce the cost of work by making perlite formulations with your own hands or purchase ready-made dry mixes.

The choice of cement for plaster

Cement is the basis of the plaster composition, and its quality depends on the brand used. The rules here are:

- In order to cover the external walls, which are exposed to temperature changes and high humidity, mainly Portland cement of the CEM 32.5 brand is chosen.

- For the treatment of internal walls, especially in dry rooms with a moderate temperature regime, ready-made compositions are used: dry mixes of grades M100 and M200.

To improve the quality of the stucco mixture, the following components are added to the composition:

- Glue components. They dissolve in water and displace air bubbles. Therefore, the plaster using these additives lays on the surface evenly, without cracks.

- Oily clay performs similar functions as the components mentioned above. The maximum level of its presence in the composition: 100 g per 15 liters of water. If this level is exceeded, the final product will be cracked after application.

- Lime paste is a useful additive that improves the adhesion of the composition. It is especially needed for indoor applications.

Varieties of plaster

The purpose of the final product affects the ingredients used and their ratio:

- To process the external walls, create a composition of cement, lime and sand. The same composition is applicable for coating internal walls in damp rooms, for example, in showers, bathrooms, basements.

- If the expected level of humidity in the room or outside is low, the plaster is made of cement, sand, clay and gypsum.

- There is a special composition for the average level of humidity. Clay and cement are added to it.

Proportions of cement and sand for plastering walls

The proportions of the components described above depend on many factors. The table below shows the main points that you need to track to get a good end product.

| Terms | Proportions (cement in relation to sand, parts) | Comments |

| Normal composition, without special restrictions and conditions | 1:5 | When mixing the composition add water to achieve the desired consistency. The volume of water is also important for obtaining a quality product and therefore is added gradually. |

| Greasy composition for coating the walls after spraying | 1:3 | Spray is the preparation of walls for applying a plaster composition. This is the preliminary stage of working with concrete walls. The liquid solution, which includes cement and sand, is applied to the wall, pre-moistened with water. |

| Cover layer | 1:1 | Nakryvka is the third layer of creamy plaster. It is applied to the ground (second layer), which was applied to the first layer - spray. |

When talking about the "part" of the components, we mean any packaging. It can be a bucket, or a shovel, or a bucket. It is important to stick to a container once selected during the entire preparation to avoid mistakes.

With a plaster layer thickness of 20 mm, per 1 sq.m. the surface requires an average of 6 kg of cement, 20 kg of sand, if a proportion of 1: 4 is observed.

The table below shows the interdependence on the composition of the plaster and the desired proportion of the components used:

| Type of solution | Splashing | Priming | Nakryvka |

| Lime (lime: sand) | 1:(2,5-4) | 1:(2-3) | 1:(1-2) |

| Cement (cement: sand) | 1:(2,5-4) | 1:(2-3) | 1:(1-2) |

| Clay (clay: sand) | 1:(3-5) | 1:(3-4,5) | – |

| Lime-clay (lime: clay) | 0.2:(1-3) | 0.2-(1-5) | 0.2:(1-3) |

| Lime-gypsum (lime: gypsum: sand) | 1:1:2 | 1:0.5:2 | 1:1:5 |

| Clay-gypsum (clay: gypsum: sand) | 1:0.2:3 | 1:0.2:3 | – |

How to cook plaster

The manufacture of plaster mortar is not limited to observing the desired ratio. No less important is how the composition is prepared. It is necessary to strictly observe the technology.

The following tips will help you get things right.

- Each dry component (sand, lime) must be passed through a special sieve before it is added to the mixture.

- Excess components are no less harmful than disadvantages. Any deviation from the ideal proportion will degrade the quality of the final product.

- An important parameter of the quality of the plaster is fat content. Its degree is determined by the tool with which the composition is mixed during cooking. If the mixture sticks to it, it means that it has a high degree of fat content. To return to the balance, sand is added - it lowers fat content. If the composition does not stick at all, then it is skinny. The hitch will be bad, and astringent components are added to improve it. Good plaster sticks to the tool, but not too much.

A greasy mixture means that more cement was taken than needed. The composition turned out to be too thick, it will be difficult to lay down on the walls. A mixture is considered lean if, on the contrary, too little cement was taken. The result of this error is the high fluidity of the composition.

The mass becomes normal when it is easy to apply to the surface, and it lingers there for a long time.

Necessary tools and materials for work

The preparation of plaster mortars begins with the preparation of the following tools:

- Mixing container (a regular plastic bucket will do).

- Capacities for dispensing components.

- A trowel for manual mixing, a drill, a perforator with a mixer nozzle or a concrete mixer for machine solution preparation.

Of the materials required:

- Astringent (clay, lime, cement).

- Filler (sand, stone chips or flour, sawdust).

- Water.

- Special additives to increase ductility, toughness, water resistance, if necessary.

Cement plaster preparation

This material is most often used for roughing the internal and external walls of residential premises.It is notable for its durability, moisture resistance and long service life, but it is difficult to work with it due to its heavy weight. In addition, it may take up to 14 days for the cementitious compositions and curing to fully dry. Do this type of plaster according to the following instructions:

- Screening sand. This procedure is carried out before preparing a solution for plastering walls, using a large sieve. It is necessary to identify and remove stones, lumps of clay and sand, which are unacceptable in a stucco mixture.

- Mixing dry ingredients. It is necessary to measure 1 portion of cement of grade M400 and higher and 4 portions of sand, then pour them into a common container and mix thoroughly with a hand tool, since using a drill at this stage will lead to the formation of a huge amount of dust.

- Adding water. The liquid must be added in small portions, constantly mixing it with a mixer. In the end, you should get a homogeneous mixture, the consistency of which will resemble thick sour cream. For machine plaster, the composition should be more fluid. Then the container is left for 10-15 minutes and mixed again.

- Add plasticizers and other special components. These substances are added at the very end in the proportions indicated by the manufacturer. At the end, the solution is mixed again, and then proceed to application.

On a note! Cement-based mortars dry for quite a while, so you can immediately prepare a large portion of the material, which is enough for the entire wall or a significant fragment of it. It is allowed from time to time to mix the finished composition with a mixer so that it remains homogeneous.

Cement-lime plaster

To increase the strength of the material, lime is sometimes added to it. Such a solution is prepared in the same way as cement, but after mixing the main components, you need to take 2 servings of lime and dilute it with water in a separate container, then mix thoroughly. The result should be the so-called lime dough, reminiscent of the consistency of ordinary batter. Then, diluted lime is added to the sand and cement mixture, and only then water and other components are added.

It is not recommended to add too much lime dough, since such a violation of technology can lead to cracking of the finished coating.

Instructions for mixing lime formulations

This material was previously used everywhere. Its main advantage is its relatively low cost and high mechanical strength. Preparation of a plaster of this type is as follows.

If quicklime is used, then considerable time will have to be spent to extinguish it. To do this, dry lime is poured into a container, after which cold water is poured into it. As a result, a violent reaction will occur, which will be accompanied by heating and spraying, so the mixture should occupy no more than 40% of the volume in the tank. When pouring liquids, protective clothing and glasses should be used. After completion of the reaction, the mixture is closed and left to infuse for 2 weeks.

After this, you need to grind the slaked lime so that there are no lumps left in it. To do this, use a sieve through which the material is ground. Before diluting the material with water, a small amount of sand is added to the lime container, and then mixed. Sifted sand is added to the homogeneous mixture in the amount of 3 parts per 1 share of lime dough. Pour material in small portions, constantly mixing and adding a little water. The result should be a solution with a density of thick sour cream.

Important! Such mixtures dry within 12-14 hours, so you need to do the plaster in such an amount that is used at a time. It is also necessary to constantly clean the nozzle-mixer after each mixing of the plaster.

Lime and gypsum materials

The manufacturing process of this material looks exactly the same as described above, but instead of adding 3 fractions of sand, you need to make a gypsum mortar. Consistency, as always, should be like sour cream. 1 part of gypsum must be diluted with water, after which add the mixture to a pre-prepared lime dough. At the end, everything is thoroughly mixed with a drill with a mixer nozzle. Depending on the required strength, you can add a little more water or add a small amount of sand.

You should know! Compositions with the presence of gypsum dry very quickly, so before you start cooking, you need to divide the wall into sections of 1 square meter and prepare as much mortar as you need to process this area.

Clay based solutions

In this case, the main component is alumina. Such plaster has been used for several millennia. The preparation of the simplest solution is as follows:

Clay based solutions

Clay based solutions

- Before making a mortar for plaster, alumina is placed in a container and water is added, and then left for 4-5 hours.

- The prepared clay is thoroughly mixed and sand is poured into it. The proportions of the mortar for plastering the walls - 1: 3. Plaster should be planted in stages, in small portions.

- Immediately after the final mixing, the solution can be applied to the walls.

Only in such a solution can water be constantly added to maintain the required consistency. In the case of other mixtures, this is strictly prohibited.

You can also prepare clay plaster with the following materials:

- Lime dough. It is added in front of the sand. The ratio is as follows: 1 share of clay needs 0.5 parts of lime and 3 sand.

- Cement. It is mixed with clay, while the proportions of the stucco mortar are 0.2: 1, after which they are mixed with 3 fractions of sand.

- Gypsum. This material will need 0.25 parts per 1 clay. First, these components are mixed, then sand is added. Such a mixture sets in a few minutes after the preparation of the solution is completed, and hardens in 30 minutes.

Additional components

To impart certain properties to the mortar for wall plaster or to improve the existing plaster, the following substances are added:

- Quartz sand. The fraction of this material can be no more than 6 mm. The substance is used to give plaster decorative properties, as well as to increase resistance to acidic environments.

Quartz sand gives the plaster an attractive appearance

Quartz sand gives the plaster an attractive appearance

Ground Mica

Ground Mica

The composition of the plaster can add no more than 10% of the above materials from the total mass.

Expert Advice

In order for the plaster to meet all the requirements, during its manufacture, you must adhere to the following recommendations:

- All dry components are sieved through a sieve.

Sifting dry components through a sieve is an important component in obtaining a quality solution.

Sifting dry components through a sieve is an important component in obtaining a quality solution.

Properly mixed plaster

Properly mixed plaster

Ready plaster mixes are made in accordance with all the rules and in any case will be better than prepared houses. Therefore, if the home master does not have experience and is not ready to spend a large amount of time and effort on cooking, it is better not to try to save, but to immediately buy liquid or dry plasters in a hardware store.

Why does one solution have different proportions

Leveling plasters consist of several layers having different functions:

- spray is designed to create a strong bond of the base material and the overlying, main leveling layer,

- the coating is intended to give the main smoothing coating the desired evenness, and sometimes smoothness (the desired surface quality for wallpaper gluing, paint application),

- soil - the main leveling material, is applied in one or more layers.

Since the functions are different, solutions differ in their proportions and components. For example, finishes need a finer filler, since the degree of roughness of the finish depends on the size of the grains. For spraying, the mixture is made thinner than for soil. Confuse compositions for different layers - violate the technology of finishing.

The period from the moment of mixing the plaster mass to the beginning of its setting is called the life time. At this time, the stucco mortar has mobility, it can be applied, giving the mixture the desired shape. Life expectancy depends on the types of components and composition. For example, gypsum has a short lifespan. To increase this period or reduce it, additives are added to the mixture - accelerators or retarders of hardening.

In addition to these additives, antifrosty (for plastering walls in winter), antifungal and other additives are introduced to give the desired mixture of qualities to the plaster mixture. Any additives require a fairly accurate dosage, as they have their own chemical formula. Their excess can significantly degrade the properties of the finished coating.

Maintaining the ratio of the components of the plaster is important. Therefore, when mixing a mixture of individual components or diluting ready-made dry formulations, observe the recommended proportions. Only in this way you will create a stucco stone with the necessary qualities.

Types of plaster mortar their composition and proportions

In fact, plaster coatings are artificial stone. We can influence the characteristics of this stone already at the stage of preparing the corresponding components, dosing, mixing, applying to the wall and creating the appropriate conditions for hardening the composition.

In the mixed composition, each of the components does its job:

- binds other components (binders, reacting chemically with water, forming crystalline bonds),

- serves as a framework already having strength, create a structure (fillers are mainly chemically inert), create a thermal or noise barrier (for example, perlite sand),

- becomes the environment in which particles of materials are placed and, at the same time, participates in the chemical transformation of the binder (water or solvents in polymer compositions),

- contribute to the quality of the solution itself and the properties of artificial stone (various additives),

- give color to the mortar and finished plaster (dyes and pigments).

Together, these components are a solution that, being transformed, becomes an artificial stone.

As binders used:

- cements (mainly Portland cement, also for stucco compounds ...),

- gypsum (alabaster and gypsum are found on the counter),

- lime (quicklime and boiling water),

- clay

- various polymer resins.

It's time to figure out how to make mortars for wall plaster from the most common materials. In the manufacture of mortars for wall plastering with your own hands (proportions are given for each type), first of all, such characteristics of binders (or bases) are taken into account, such as:

- brand (strength of a cube of stucco mixture based on gypsum or cement),

- fat content (for example, clay or lime) indicates an increased content of binders,

- water content.

The composition of the plaster mortar is determined by the standard SP 82-101-98 Preparation and use of mortars. It is worth paying attention to the fact that the standard does not indicate all possible proportions of solutions (for example, the data of a sand-and-sand solution are given without taking into account the fat content of the test). In our article we will indicate the data from the standard and the proportions of the stucco mortar, taking into account all the possible nuances.

Cement-sand mortar and proportions

Two proportions for cement mortar:

- in some cases, weight proportions are used, in which the weight of the components is indicated,

- volume ratios are more often used, for example, the usual 1: 3 cement-sand composition is prepared as follows: 3 buckets of sand are measured out on 1 bucket of cement.

We will operate with volumetric relations.

In the case of leveling plaster for the mortar take the following proportions of cement and sand:

| Name | Proportion | |

|---|---|---|

| Cement | Sand | |

| Spray | 1 | 2,5…4,0 |

| Priming | 1 | 2,0…3,0 |

| Nakryvka | 1 | 1,0…1,5 |

If such not very accurate relationships are found, then they are guided by what solution is obtained upon mixing. For example, if the solution turns out to be greasy, then the filler fraction is increased; if the mixture is lean, the sand fraction is reduced.

Lime mortar for plastering walls - proportions

Lime is introduced into the plaster solution in the form of milk (emulsion) or lime paste. To breed dough for milk should be in advance. If the composition is prepared manually, then use milk. It is allowed to put the dough into the water in the mixer, giving it time to disperse when the pear rotates.

The composition of the mortar for plaster is selected by making several samples. It depends on how greasy lime is.

The volumetric ratio (the volumetric part of the test is indicated) is taken with a bold sign:

| Name | Proportion | |

|---|---|---|

| Lime dough | Sand | |

| Spray | 1 | 3,6. 4 |

| Priming | 1 | 3,6. 4 |

| Nakryvka | 1 | 2,5 |

With lean lime:

| Name | Proportion | |

|---|---|---|

| Lime dough | Sand | |

| Spray | 1 | 1,5…2,0 |

| Priming | 1 | 1,5…2,0 |

| Nakryvka | 1 | 1 |

For lime with medium fat content:

| Name | Proportion | |

|---|---|---|

| Lime dough | Sand | |

| Spray | 1 | 3,0…3,5 |

| Priming | 1 | 3,0…3,5 |

| Nakryvka | 1 | 2 |

The proportions of lime-sand mortar in accordance with the standard:

| Name | Proportion | |

|---|---|---|

| Lime dough | Sand | |

| Spray | 1 | 2,5. 4 |

| Priming | 1 | 2. 3 |

| Nakryvka | 1 | 1. 2 |

Clay plaster

The ratio of the components of the clay mortar for wall plastering depends on the degree of clay fat. Clay-based mixtures are kneaded with the same composition, regardless of the place of the applied layer (it doesn’t matter if it is sprayed or coated). The ratio is 1: 2.5 ... 4.0 (more accurate proportions are selected by trial or experimentally). The clay fat content is tested by hand (they are making koloboks or rolling and twisting bundles).

Gypsum-gypsum mortar

This, according to the classification, a complex composition with two binders is used to align the internal walls. In the formula, the first indicates the number of parts of lime, the second - gypsum.

| Name | Proportion | ||

|---|---|---|---|

| Lime dough | Gypsum | Sand | |

| Spray | 1 | 0,3. 1,0 | 2,0. 3,0 |

| Priming | 1 | 0,5. 1,5 | 1,5. 2,0 |

| Nakryvka | 1 | 1. 1,5 | 0 |

It can be seen from the formulas that gypsum is not mixed into the solution for coating.

Cement-lime mortar

A complex mortar for plaster is also obtained when lime is added to the cement-sand composition. In the formula, the order of indicating the proportion of components in the sequence is cement: lime: sand.

| Name | Proportion | ||

|---|---|---|---|

| Cement | Lime | Sand | |

| Spray | 1 | 0,5. 7,0 | 4,0. 6,0 |

| Priming | 1 | 0,7. 1 | 3,0. 5,0 |

| Nakryvka | 1 | 1. 1,5 | 1,5. 3,0 |

Binder in plaster

If only one binder is included in the plaster solution, the composition is called simple. If the binders are two or more - complicated. Not all binders get along with each other. For example, gypsum with cement is chemically unfriendly to each other. Therefore, they are used individually or with other binders.

All binders, except polymers, are minerals, which is why plasters have the same name. Gypsum, cements and lime are pre-treated thermally, as a result they lose water and are able to react to its presence. Combining with water, these substances form saturated solutions and create crystals.

Plaster fluid

The water in the solution usually contains more than is required for the formation of crystals. A liquid is also needed to give the mixture mobility (workability). In this case, excess moisture can be harmful (the strength of the solution decreases). For this reason, the ratio of water to other components must be observed.

Fillers

The manufacture of binders, in addition to clay, requires a lot of costs, so they cost much more than such fillers as sand or sawdust. In addition, a solution containing only binders cracks when hardening. Therefore, to reduce the amount of binders (cost of the solution), as well as to reduce cracking, fillers are introduced into the composition.

Fillers also give a certain structure to the solutions, for example, coarse grains use coarse sand, for other decorative mixtures, artificial or natural fibers, shell fragments are used as fillers.

Decorative mixtures are best purchased ready-made. Their composition was developed and tested in practice by specialists.

Rough (leveling) plaster more often than other components must be prepared on the spot. The consumption of the leveling plaster mixture is greater, and the cost of the self-made mixture is lower.

Special additives in plaster mortars

To give the mortar for plaster the desired properties, apply modifying additives (universal and narrowly targeted). Additives have an effect on the binder (cement), enhancing or leveling its individual properties.

In solutions, additives perform the following functions:

- accelerate / slow down the process of crystal formation (setting), for example, for gypsum, the moderator is bone glue, milk, PVA,

- increase frost resistance (ferric chloride and other salts),

- improve ductility (they serve for some water retention in the solution, interfere with the process of delamination of the mixture), for example, liquid glass,

- increase the strength of the mixture (for example, reinforcing fibers (fiber) or additional binders).

The specificity of the plaster composition

Since it is necessary to plaster buildings outside and inside, where the finish has been in varying conditions for a long time, the composition of the mortar for plaster is also specific. Facade surfaces are subject to more severe mechanical stress, rain, rain, hail, endure frost and heat, scorched by direct sunlight. Therefore, solutions for external conditions should be more resistant to all these "troubles".

There are mixtures for facades, interior work and universal. The latter can equally be used for outdoor decoration and indoors.

All basic data on the proportions of stucco mortars for exterior and interior decoration are contained in the table from the standard.

The following figures show the proportions of the coating.

The composition of the mortar for exterior wall plaster

Solutions for exterior walls are distinguished by their basis. For exterior decoration, gypsum and lime compositions are not used. An exception is the plastering of closed loggias and balconies, where there is protection against ingress of water. Therefore, the main binder for facade compositions is cement. Also used are cement-lime (popular) and cement-polymer (more expensive) compounds.

Clay is not afraid of frost and sunlight. But clay plaster must be protected from blur. For facades in regions with a dry climate, if water does not directly enter the plaster, plastering with lime-clay and lime-gypsum mixtures is used.

Increased mechanical loads (shock and abrasion) require increased strength of the plaster coating. Therefore, cements take high grades (not lower than M500). In areas with high vibrational loads (for example, near railway tracks) it is better to use cement-polymer mixes.

As for street mortars for wall plastering, the proportions of the compositions used in temperate climates are as follows:

- cement (with plasticizer) - 1: 6,

- cement-lime (lime as a plasticizer) - 1: 1: 6,

- dry mix masonry cement (already contains plasticizers) - 1: 5.

For harsh climates:

- cement (with self-addition of plasticizer) - 1: 4,

- cement-lime (see above) - 1: 0.5: 4,

- cement-masonry mixture - 1: 3.

The composition of the plaster for interior work

As for materials for indoor work, mixtures on any basis are suitable here. The proportions are indicated above. It should be borne in mind that plasters have different vapor permeability, which means that for bedrooms, children’s, living rooms it is better to use those that breathe better.

For bathrooms, bathrooms and wet basements, gypsum and lime mixtures without special protection are preferably not used.

For internal work, gypsum mixtures are most often used for leveling. Composition: 6 parts of gypsum + 2 water + 0.2 PVA.

How to mix plaster

To prepare mortars for wall plaster, adhere to a certain sequence of kneading. If the binder and filler are loose, and the composition is kneaded manually, the dry components are pre-mixed.

After that, liquid components are added to the tank. In this case, liquid additives (for example, milk of lime) are added to water in advance and stirred. In this sequence, it is possible to prepare a plaster mix with a uniform distribution in the mixture of all components.

If the batch is prepared in a mortar mixer, water is poured first and the engine is turned on. Then there are added other liquid components. Then pour cement and sand. It is not recommended to fill the entire volume of water into the mixer immediately, since the sand is usually wet. And excess water in solution is useless. Do not forget about maintaining proportions for the plaster.

Ready plaster mixes

It is easier for beginners to use ready-made plaster mixes that are produced by various companies. The finished mixture already contains various additives, so you can not expect "surprises" from the behavior of the solution when laying on the wall and hardening the mass. On the package there is information on how to properly knead, the specifics of the composition and its characteristics.

Dry mixes are prepared according to the instructions that can be found on the packaging. During transportation, partial settling of heavier filler particles in the package is possible. Therefore, in order not to get some deviations in the compositions of different batches, it is recommended to dilute the whole mixture (the entire package).

Finished compounds have an expiration date. It’s better to buy mixtures that are still far from expiration. In order for the finish made on large walls to be uniform, it is better to take mixes for preparing plaster from one batch.

Preparing a mortar for plaster is a seemingly simple job. But the quality and properties of the finish depend on how well and correctly the plaster mix is prepared.