This article is for people who are eyeing a parquet board as a floor covering. We at STP have been working with parquet for more than 10 years and will show you what to look for when choosing a parquet board.

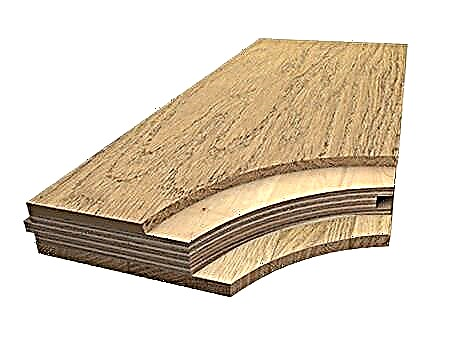

Parquet board is a kind of a wider class of floor coverings - engineering parquet. The essence of engineering parquet is a two- or three-layer, transversely glued die design. Moreover, a valuable species of wood is present only in the upper facial layer with a thickness of 3 to 6 mm. In the production of the lower layer, manufacturers use various materials: it can be plywood, coniferous lamellas or oak battens. This design is designed to make the board stable and resistant to changes in temperature and humidity.

A batch board is usually called an engineering board with a lock connection - a cheap and quick flooring in laying, the quality and service life of which correspond to the price.

Yes, there is a premium class parquet board - but this is an exception to the rule, we will dwell on it below.

Here are some design options:

Sizes of a parquet board:

· Length: 1200-2500 mm.

· Width: 100-300 mm.

· Thickness: 12-22 mm (the most common board is 14 mm)

The thickness of the upper face layer determines how many times the floor of the parquet board can be updated - looping. The thicker the front layer, the more times you can update the floor, the theoretically longer floor will last. Why theoretically? Because the service life depends on other factors. For example, the adhesive used to glue the layers is critical. In the manufacture of cheap parquet boards take water glue with low performance and short life. The board can just stick up, so that the turn does not reach the hitch.

The external, front layer of a parquet board imitates a massive board (single and double-lane) or classic piece parquet (three-lane).

three-lane oak single-lane oak

Oak and ash are most often used as the top layer. These breeds are accustomed to the peculiarities of our climate; they tolerate changes in temperature and humidity.

But it's not only that. The trick is that it is oak and ash that are better than other types of wood and can be tinted, aged and brushed (the surface acquires a contrasting structure with noble “wrinkles”), which gives unlimited possibilities for the flight of design thought.

One thing but! If you have a brightly and densely tinted parquet board, then it is likely that wood with knots and sapwood is hidden under a bright color, and after the first grinding you will be disappointed.

A board made of exotic species looks very impressive, but costs more than oak. Exotic breeds from South America, Africa and Southeast Asia are “capricious” in our climate, therefore we need regular and professional parquet care.

Advantages and disadvantages of a parquet board

Parquet board was originally conceived as an inexpensive copy of the classic piece parquet and solid board. But, like any copy, it is inferior to the original. Its main advantages are low cost and high laying speed. Due to the castle connection, the board is laid 4 times faster than classic parquet (up to 40 m 2 per shift).

Alas, there are no more advantages. More precisely, there is, but only in the advertising, which came up with marketers. For example, they write that the varnish layer is dried by ultraviolet and this is very cool. In fact, ultraviolet serves to accelerate the drying process of the varnish, and absolutely does not affect the quality of the varnish film.

First: Number of stitches. The thickness of the upper layer of the floorboard is only 3-4 mm, which means you can cycle it about 2 times. This significantly reduces the floor service life (again, if the board does not dry out earlier due to cheap glue and improper installation). For comparison, piece parquet can be looped up to 6 times, a massive board - up to 10 times. Accordingly, their service life is 3-5 times longer.

Second. The low cost of a parquet board is achieved by the low quality of the board and a thin layer of varnish, which is why grinding will be required after 2-3 years of standard operation.

These shortcomings can be avoided by buying a board of the PREMIUM class, at a price of 4,500 rubles / m 2. Her characteristics are close to real parquet and, if laid by gluing it to a quality base, the floor will last a very long time. But then the question arises - why buy a parquet board at such a price? At such a cost, it is more profitable to lay a classic piece parquet or massive board, which will last 3-5 times longer.

Weigh the pros and cons. Parquet board is cheap flooring, but it has disadvantages. The question is whether you are ready to put up with them, given the price.

Under varnish or under oil?

The parquet board is varnished or oiled at the factory and comes with a finished finish.

Lacquer creates a polymer film on the surface that protects it from pollution and external influences. The lacquer exhibits a wood texture and is available in matte and glossy versions.

Butter penetrates into the pores of wood and after drying forms a protective and decorative coating resistant to dirt and able to withstand high abrasion loads, it allows the parquet to “breathe” and makes the floor more natural. Modern oils can create the effect of a varnish film with a glossy and semi-gloss display.

Parquet oil as a topcoat is a sign that the board belongs to the premium segment. A single-lane parquet board in most cases is coated with oil. We recommend choosing natural colors of wood without tinting, because the beautiful texture of the premium board does not need masking tinting.

Parquet laying

In this matter, the system of connecting the boards matters, there are two of them:

thorn groove connection

Laying a parquet board occurs in two ways:

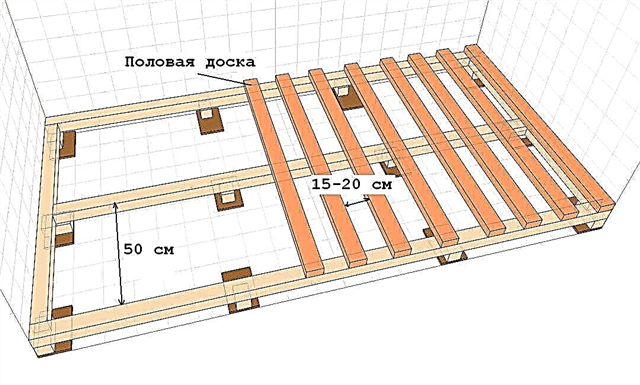

1) classic way - gluing to the base. In this way you can stack a board of both types, it is more reliable, preferred when laying on heated floors. For bonding, you need to use elastic polyurethane adhesive on MS-polymers, it creates a sound-absorbing adhesive joint with a vapor barrier effect.

2) floating way - boards with a lock connection are attached to each other, but not attached to the base, suitable only for a lock board.

The floating method made the styling lightning fast. True, I had to sacrifice reliability - over time, the castle joints weaken and cracks appear. This method is used in budget office rooms where the floor service life is not so important - you still have to change after 4-5 years. Add to this the limitations on installing heavy built-in furniture, plus the noise of the “floating floor” and the advantages of this technology are not obvious.

First of all, the service life of a parquet board depends on laying. Therefore, give brigade selection special significance. In detail we consider laying parquet boards on this page. Follow the link and let your new gender serve for more than a dozen years.

Installation of a parquet board

Based on the design of the room and its purpose, installation of the parquet board can be done in several ways: square, herringbone, deck or diagonal way. It is good that this flooring avoids sanding the floors and applying varnish to them. Upon sale, parquet boards are completely ready for use. Their top layer looks flawless and varnishes during the manufacturing process. The surface of the parquet board varnished in the factory is beautiful and durable.

Types of parquet board

It is difficult to distinguish single-lane parquet boards from ordinary wooden boards. This type of flooring looks great in rooms with a large area. The cost of a single-lane board is much higher, since its manufacture uses wide strips of high-quality wood. In width, such a board is most often 137 mm. Some manufacturers produce single-lane parquet boards with chamfers at the edges. After laying, a groove is formed between adjacent boards, which imitates the seams and allows you to achieve the full effect of solid wood flooring. It looks very impressive, but for parquet boards this technique is not recommended. During further operation, dirt is clogged and moisture penetrates into the grooves, and since the parquet board is not 100% made of valuable hardwood, this can cause warping. Coniferous wood, which is not distinguished by moisture resistance and hardness, usually acts as the basis of a parquet board.

Two-lane parquet boards - a combination of two wide strips of valuable wood, which can be laid either in continuous strips or in separate modules. The large width of the planks of such boards allows you to give the premises a solemn appearance. It is often used for laying flooring in rooms decorated in a classic interior. It is better to use a two-lane board on large areas.

Three-lane parquet boards are considered the most common option. The working layer of such boards is made up of three parallel strips of valuable wood. As a rule, the planks on such boards are divided into separate modules, that is, divided into short segments, and not laid in long solid strips. Three-lane parquet boards are a reproduction of the popular parquet pattern “deck” and are suitable for decoration of almost any room. The width of three-strip boards is approximately 190–208 mm.

Four-lane parquet boards are made, for the most part, from wood waste. The stripes that make up them are very narrow, because on the floor they look too colorful. This design option is great for a country house. But it is worth considering that stable temperature and humidity conditions are important for parquet, therefore its use in unheated rooms in winter is impossible.

The advantages of flooring

The most important advantage of a parquet board is that after the acquisition it does not require any additional actions to be performed on it. The flooring from parquet boards does not need to be scraped, sanded and varnished in several layers. All this work is being done at the factory. The main task of the buyer is only the correct installation and maintenance of the surface. The surface of the parquet board is impregnated with a special composition, which helps to improve the appearance of the coating and increase its durability.

The manufacturing technology of parquet boards provides this material with flexibility and resistance to changes from external influences. A pair of separate wooden coniferous dies are glued to the plywood base. The front side of the parquet board is made of veneer of valuable wood. Its thickness, as a rule, is from 4 to 6 mm. The durability of the flooring depends on the thickness of this veneer.

The manufacturing technology of parquet boards provides this material with flexibility and resistance to changes from external influences. A pair of separate wooden coniferous dies are glued to the plywood base. The front side of the parquet board is made of veneer of valuable wood. Its thickness, as a rule, is from 4 to 6 mm. The durability of the flooring depends on the thickness of this veneer.

An interesting feature of a parquet board is the possibility of its dismantling without the risk of any consequences. So, flooring from parquet boards can be easily assembled and disassembled without compromising on quality. If you plan to move or decide to install a warm floor, then the parquet board is easily dismantled. In this case, the material will not receive any damage and will be ready for further effective operation.

Of course, this is not the cheapest coating, but when compared with parquet, the difference will be very noticeable. Flooring from parquet boards is an ideal solution for creating effective flooring from valuable wood species with minimal financial costs.

Convenient locking connection greatly simplifies the technology of laying floors from parquet boards. The entire list of works can be carried out independently, without using extraneous, sometimes expensive, help.

The use of tinting compositions in the manufacture of parquet boards makes the choice of its colors and textures almost unlimited.

Disadvantages of a parquet board

Parquet boards, like any other floor covering, are not without drawbacks that must be taken into account, I make independent laying of the floor:

- the parquet board is not moisture resistant, therefore, during its installation it is necessary to take a number of additional measures to protect it,

- the one-sided orientation of the planks hides the depth and volume of the wood texture, so curly styling is unacceptable,

- the choice of lamella patterns for the top of this flooring is very limited,

- when installing the floor from parquet boards, different in texture and color, only one manufacturer and a specific series of products can be used,

- there is a risk of delamination of the material, which may cause improper operation or violations in the production technology or during the installation of the floorboard,

- due to the small thickness of the front layer of valuable wood, the number of possible operations for cycling is limited, when compared with the classic parquet,

- the difference in the coefficients of thermal expansion of hard rocks of the upper and middle layer becomes especially significant when the compensating layer is made of spruce,

- the presentation during installation of flooring high requirements for the base surface of the floor,

- the quality of execution and the reliability of the locks is greatly affected by the density of the connection.

All the existing shortcomings overlap the functionality of the floorboard and its practicality in operation. A lack of moisture resistance can compensate for proper styling.

Parquet Board Myths

1. Lamellas of hard / valuable wood of the upper layer and conifers of the remaining layers are naturally dried.

This is a clear invention, since the natural drying of the main tree species (ash, oak, hornbeam, beech) takes place over three to five years, and ebony, mahogany and other valuable tree species - five to seven years or more. Therefore, it is unrealistic to carry out under conditions of mass production of parquet boards.

2. In order to glue separate layers of the parquet board, only compositions of natural components are used.

The production of any composite materials, which include both model parquet and parquet boards, involves the use of high-tech organic adhesives based on synthetic polymers, although harmless to human health.

3. Lock systems will be able to provide the fullest connection density even with five to seven times re-installation.

In fact, the dynamic loads that are transmitted to the floating floor cause gradual wear of the material, it becomes more significant when using a soft breed of wood into which the castle is milled. Therefore, each new re-laying of flooring from parquet boards increases the risk of operational cracks.

Parquet board structure

All the advantages and disadvantages of a parquet board are based on its structure, which is represented by three layers of wood, each of which is perpendicular to the other two.

Top layer (decorative) - made of wood of different species (oak, beech, maple, bamboo, etc.), thickness up to 1 to 6 mm.

Middle layer - made of coniferous wood and determines the operational characteristics of the coating.

The bottom layer (stabilizing) is represented by the veneer of coniferous wood, a thickness of about 1.5 mm.

Based on the features of the structure, we consider the advantages and disadvantages of a parquet board.

Advantages of a parquet board:

Laying the flooring is much faster and easier than installing piece parquet. This is primarily due to the large size of the individual elements of the material. At the same time, laying can be done independently even without special skills and installation experience.

Parquet board is an environmentally friendly and natural floor finishing material, as it is made only of wood.

Design features of the parquet board protect the finished floor from deformation and damage. The multilayer structure makes the coating more resistant to moisture, temperature extremes and other atmospheric factors.

Individual elements of such parquet are not able to accumulate static electricity, which makes the material very pleasant to the touch and improves tactile sensations.

Parquet board has a fairly high level of sound absorption, which eliminates the use of additional acoustic barriers.

The species range of this material is so large and diverse that it allows you to choose the option suitable for any interior solution.

Disadvantages of a parquet board:

Instability of the material to mechanical, power and shock loads. This is due to the insignificant thickness of the upper layer of wood, which takes on the main "blow". In this regard, scratches and shallow dents from furniture on the parquet board appear quite often.

A relatively short maximum service life, which is from 12 to 20 years, while the massif and classic parquet with proper care can last up to 50-70 years.

The complexity of the restoration. Renovation of natural wood coatings involves scrapping the floor, which is the removal of a small thickness of wood using a special machine. Parquet board has an insufficient thickness of the decorative layer for multiple looping. Moreover, you can cycle the board if it is glued.

The individual elements of the floorboard are impressive in size, which does not allow for curly styling and the formation of artistic patterns and drawings.

When significant deformations and damage occur on certain areas of the floor, the replacement of the element involves the removal of a sufficiently large area, since the average length of the parquet board is about two meters. In this regard, small piece parquet dies are much easier to replace. In addition, it is quite difficult to choose the right color and texture pattern of wood, therefore, when calculating the amount of material required for installation, it is necessary to take into account several additional boards that may be required for restoration of the coating.

Despite the fact that like any other natural flooring, parquet board has several disadvantages, its use in the interior is justified by numerous advantages. So, for example, the modern way of life of a person often does not require such durability of the floor as a massive board and piece parquet have, since the interior can change after numerous repairs. When moving, the laid parquet board can be dismantled and laid again in another room. Based on all of the above, it is possible to draw an unambiguous conclusion that a parquet board has significantly more significant advantages than disadvantages.

Pros and cons of laminate flooring

If you are interested in the question of what to choose: parquet or laminate, we advise you to learn more about the advantages and disadvantages of each type of floor.

Let's start with the laminate: this coating differs from most flooring materials in its multilayer structure. Layers are created by combining wood fiber boards and kraft paper, which are combined using polymers.

For added protection, manufacturers create an outer layer of laminate that emphasizes a specific coating design. The protective layer is based on melamine resin, which significantly increases the density and durability of the laminate.

Laminate fiberboards allow the coating to acquire the required size and shape, and also provide additional protection against climate change. To resist moisture, the edges of the inner layers of the laminate are treated with a special wax-based impregnation.

In the market of finishing materials for the floor, you can find different types of laminate. It is very important to choose a sufficiently strong coating, since not all varieties of this material are equally resistant to high loads.

Remember! The marking indicated on the laminate will indicate what kind of loads the coating can withstand. This helps to determine the material for flooring in rooms with different purposes.

So what are the benefits of helping you distinguish between laminate flooring and parquet? The modern laminate has many advantages, and here are the main ones:

- the coating does not attract dust, therefore, does not require daily cleaning,

- the laminate has high wear resistance and is immune to accidental shocks. The classes of laminate 31-33 will have maximum strength, but for an apartment, coatings of class 21-23 are also suitable,

- with constant exposure to sunlight on the surface, the color of the laminate will not change,

- the coating withstands thermal effects, so you can lay a warm floor under the laminate,

- chemicals can be used to clean the surface,

- the laminate is great for interior decoration due to the wide variety of patterns and shades,

- when you purchase this coating from official manufacturers, you get a five-year quality guarantee.

As for the minuses of the laminate, the main one is insufficient moisture resistance. Therefore, in the bathroom, bathroom and other rooms with a high level of humidity, it is better to lay other floor coverings. Another minus is soundproof properties. Laminate can protect you from external noise only when using an internal substrate.

In case of damage, the laminate cannot be repaired. Therefore, be extremely careful with such a coating, otherwise you will have to splurge on a new one. The laminate is also inferior to natural materials in appearance: the top layer of this coating confirms its artificial origin.

Advantages and disadvantages of a parquet board

Now let's find out what is the difference between a parquet board and a laminate. Parquet flooring is also multilayer, but includes planks connected perpendicularly.

Due to this arrangement of layers, parquet has a long service life, high wear resistance and is immune to mechanical stress.

To understand the advantages of a parquet board over a laminate, let's learn more about its structure. The outer protective layer is created from varnish. Varnish is applied to valuable species of beech, ash, oak or other trees. The width of the wood layer is up to 6 mm.

Under the wood cover is the central layer, consisting of lamellas or narrow boards. They are connected to each other using side mounts. The plank layer is perpendicular to the layer that goes above it.

The bottom layer of the parquet board, designed for its durability, is created from 2 mm plywood on the basis of pine or spruce. Plywood fibers are arranged similarly to wood fibers of the upper layer.

So what are the advantages and disadvantages of the floorboard can affect your choice?

Here are the main advantages of this coverage:

- reliable protection against noise thanks to a natural tree as a part,

- no dust accumulates on the coating,

- for the treatment of the outer layer, manufacturers use safe varnish without formaldehyde,

- the parquet board can be sanded and restored: the number of such manipulations will depend on the width of the coating. However, not all masters are ready to take up the processing of flooring,

- high-quality parquet has a spectacular appearance and looks advantageous in any interior due to its naturalness,

- the parquet board is easy to install and does not require extremely complicated cleaning,

- Warranty for this type of coverage may exceed 10 years.

The disadvantages of the parquet board include moisture intolerance, faster abrasion of the varnish protective layer compared to the laminate, as well as the need to maintain a normal microclimate in the room where such material is laid.

Make a choice

Which is better, parquet or laminate? To answer this question and make the right choice, let's compare the laminate and the parquet board.

The main selection criteria will be wear resistance, tolerance of temperature changes and moisture, external characteristics, surface care features, as well as cost differences.

If we analyze how the laminate differs from parquet in terms of resistance to external damage, then, clearly, you should opt for a good quality laminate. Such a coating will withstand high weight loads, and even after a certain period of operation, dents, beveled zones and cracks will not appear on the surface.

Tip: thanks to this difference between laminate and parquet, you can easily rearrange furniture in your home.

How does a parquet board differ from a laminate in resistance to temperature and moisture? Again, the laminate will show you its best qualities. The difference between a parquet board and a laminate is that with excessive moisture or dry air, the material will crack or swell accordingly.

Laminate can withstand changes in the microclimate of home premises and even endure the heating season without problems.

Nevertheless, we do not recommend even laying such a coating in the bathroom, where not only moisture but also steam will affect the surface.

The advantages of parquet over the laminate relate to its appearance. Despite the fact that the laminate can be considered a more practical and versatile coating with a similar design (see laminate options for a parquet board), natural parquet will always look more advantageous.

But it will be better if you make your choice, focusing on the particular style of your room: for example, in the interiors, modern or high-tech laminate will also be appropriate.

The difference between the floorboard and the laminate is also manifested in the ease of maintenance. It is always easier to take care of artificial materials, so the laminate for this attribute is chosen more often. To clean the surface, you can regularly wash the laminate using water and gentle household products.

In the case of parquet, it is necessary to minimize wet cleaning, and if you carry out a similar cleaning of the surface, then be extremely careful.

Tip: use for cleaning special products designed for the parquet board, which will give additional shine to the varnish coating.

Parquet flooring or parquet laminate is considered one of the most expensive materials for flooring. But you can find more budget options of not very high quality, if the operating conditions allow the use of coatings with less wear resistance or resistance to external influences.

If you compare a laminate and a parquet board, then a laminate with optimal characteristics will be several times cheaper.

You can find out more about the varieties of linoleum here: types, classes, optimal thickness are described, an overview of the main manufacturers is given and a rating of the best is presented.

The procedure and main stages of repair in the apartment are in the article at: http://kvartira-rf.com/obustrojstvo/remont/svoimi-rukami.html

Questions about laminate flooring and parquet

Can laminate flooring be laid on old parquet?

Can a laminate be laid on a parquet board? Yes, like any other wooden floor. But such an installation can only be carried out with a strong deterioration of the old coating. In addition, if you are interested in whether it is possible to lay the laminate on the parquet floor, you should also understand all the intricacies of this process.

How to lay a laminate on a parquet floor depends on its condition. It is possible that you will have to start by eliminating voids in the surface of an obsolete coating. Strengthen the shaky parts, and cover the holes with elements of chipboard or wood. Also make sure that the old floor does not creak. After laying the laminate on the floor, you can not fix this shortcoming.

If you are interested in whether it is possible to lay the laminate on the parquet, then check out the basic installation steps. After checking the parquet for strength, restoration and puttying of individual areas, thoroughly clean the surface from contamination. Go through the primer, and then let the floor dry. And only after that start laying the backing and laying the laminate on the parquet floor.

What is more expensive: parquet or laminate?

If you are looking for cheaper laminate or parquet, choose a quality laminate, as its cost will be much lower than the price of parquet even of the worst quality.

What is the difference between a parquet board and parquet?

Differences between parquet and parquet board consist in the principle of production, appearance and operational characteristics. For example, parquet is a material made of solid wood, and a parquet board consists of several layers.

Parquet tolerates moisture worse and reacts negatively to microclimate changes. But the parquet board is more difficult to install on the floor.

As for appearance, the parquet board is immediately treated with protective oil or varnish.

Therefore, when choosing which is better, parquet or parquet board, start from the characteristics that are most important to you.

Which is warmer: laminate or parquet?

These coatings are facing, so floor insulation must be carried out due to the additional substrate. The difference in the warmth of the parquet and the laminate will depend only on the type of interlayer that you choose.

How to distinguish parquet from laminate?

What is the difference between a laminate and a parquet board? First of all, in the naturalness of such coatings. Therefore, carefully examine the surface: if it is natural, you will not see a repeating texture.

If the coating has been used for a long time, it is possible to distinguish between laminate and parquet according to the changes that appear due to moisture or weight loads.

Is there an alternative to laminate and parquet?

An alternative to laminate and parquet can be any cladding, depending on what criteria you choose. The closest option is a natural cork.

Reviews

If you have not yet decided what to choose, a parquet board or a laminate, find out more about how these materials actually manifest themselves.

We present you some reviews, which is better, parquet or laminate:

Sergey, Moscow: When I made repairs, I decided to focus exclusively on natural products. Therefore, I settled on the floor: naturalness and naturalness are the main differences between a laminate and a parquet board. The operational characteristics of the material are no less pleasing than its appearance.

Alena, Voronezh: I was looking for a floor covering, examined a parquet board and a laminate, I did not know which is better from these materials. Therefore, I began by studying the pros and cons of laminate flooring and parquet.

The choice fell on the laminate, as it seemed more durable and reliable.And I was right: six months have passed, and the floor is like new.

Valentina, St. Petersburg: What is the difference between parquet and laminate, what is better and how to choose high-quality material, it was not clear to me, as a girl, who had no relation to repair before. Therefore, she trusted the experts: they picked up a parquet laminated board for the design of the room at a very affordable price.

I am pleased with the strength and durability of the material, and, of course, the appearance. I think the new floor will serve me for many more years.

Nikolay, Tomsk: I decided to read reviews, what to choose: a laminate or a parquet board, but I saw that the first and second types of coatings have many advantages. But the difference between parquet and laminate is its service life.

I decided that I would spend money on a more durable coating, so I chose a parquet board with a guarantee from the manufacturer.

Now you know the difference between laminate and parquet, and you can choose the best material for your home. We advise you to pay attention to the nature of the room (it is better not to lay such floors in the bathroom), as well as to build on your preferences for strength, the appearance of the product and its price.

The production of parquet boards has the following features.

The middle layer when bonding is laid perpendicular to the upper and lower. This is done so that temperature and humidity fluctuations do not lead to deformation of the material.

The top layer of the parquet board is varnished and special compounds. They protect the external surface from moisture and abrasion.

In order for the parquet board to acquire the necessary performance characteristics and color, the top layer is made of various types of wood. The most common are oak, beech, birch, ash, cherry and walnut. Of the exotic species in the manufacture of flooring, jatoba, wenge, merbau, teak, dussia and others are used.

Varieties (grades) of parquet board

Here it is worth starting with the fact that the wood from which the upper layers of parquet boards are made is sawn in three ways.

Rustic - at various angles.

Tangential - tangent to the thickness of the trees.

Radial - along the trunks.

After manufacturing, the materials are selected and sorted. When distributing, specialists look at the color scheme and texture of wood, as well as the method of cutting and the presence of defects. Depending on the material used for the manufacture of parquet boards, lots are assigned varieties. There are three of them.

- "Rustic." The manufacture of the upper layers is wood, sawn at different angles. Small pits, irregularities and other defects are allowed. The colors of the planks may vary.

- "Natur." For the manufacture of the upper layers is wood sawn radially and tangentially. Minor color differences and very slight defects are allowed.

- "Select". The upper layers are made of wood, sawn only radially. Lamels are carefully selected in color and structure. Defects are completely absent. Parquet board "select" is more expensive than the rest.

How to choose a parquet board

The choice of flooring directly depends on the following factors.

- The thickness of the top layer. The thicker the parquet board, the more times you can update the flooring.

- Wood. When choosing, take into account its strength and moisture resistance. For example, teak and thermoash are best suited for laying in the bathroom and other rooms with high humidity. In rooms with normal conditions, the list of options is expanding significantly.

- Coverage The best choice is special parquet oil.

- Sizes. In rooms with severe loads, small parquet boards are laid on the flooring, and in normal conditions - medium and large.

Styling methods

Professionals use two methods of laying parquet boards.

- Castle. A vapor barrier is placed on the floor. Masters lay a parquet board on it, connecting the lamellas with each other using locks.

- Glue. Parquet board is attached to a flat surface with glue. To enhance the adhesive properties of the master use a primer.

Note! Do not lay the floorboard yourself if you are not confident in your abilities. Mistakes made will lead to damage to the floor covering over time and the need for costly repairs.