In the market of polyurethane polyurethane foams, there are two main types of cylinders: the so-called household with a plastic tube and professional with a valve under the gun. It is generally accepted that “homemade goods” are used for household foam, in which such a need arises extremely rarely, and therefore it makes no sense to splurge on a professional gun. Professional installers prefer professional foam due to the fact that it is more convenient and faster to apply it from a gun, and the foam itself is superior to household foam in its characteristics. But is professional foam better than household foam in all its characteristics?

What makes the difference

The difference between household and professional foams is determined mainly by the difference in the conditions for the passage of foam through a plastic tube and through a gun. Technologists, knowing these features, make adjustments to the recipes for household and professional foams, but they can’t completely level the difference created by the plastic tube and the gun.

Output volume

With the same filling of cylinders, the output volume will be higher for professional foam. The design of the gun and its adjustment also affect the output volume and other characteristics of the foam. Experienced installers will always be able to adjust the gun so as to obtain the maximum possible result.

Foam structure

Foam from a balloon with a tube forms a denser structure than foam from a balloon with a gun. This is logical: the smaller the output volume for the same mass, the higher the density.

Thermal insulation characteristics

The thermal insulation characteristics of the foam are influenced by several factors, one of which is density. The denser the foam, the better thermal insulation it provides. Consequently, a denser foam from a balloon with a tube has better thermal insulation characteristics than foam from a gun.

Secondary expansion

This is an important parameter. It shows how much fully polymerized foam will increase in volume compared to just applied. Here the difference between household and professional foams is enormous: depending on the recipe used by different manufacturers, different secondary expansion of professional foam is in the range of 15-60% (15-30% for KUDO PROFF ABSOLUT and up to 25% for KUDO TREND), whereas household expands by 200 and even 300%! These features must be taken into account when applying, because if you apply too much foam, it will begin to put pressure on the window or door frame when expanding and can deform it. Therefore, household foam must be applied to the opening in smaller quantities, making allowance for the fact that it expands 5-10 times stronger.

Application temperature

The temperature range of application of professional polyurethane foams is much wider than that of household foams, especially at low temperatures. So, for example, the professional KUDO ABSOLUT PROFF 65 ++ ARKTIKA NORD foam remains operational at a cylinder temperature of -10 ° C and outdoor temperature of -25 ° C, while household KUDO HOME 50+ ARKTIKA can only work when the cylinder is cooled to 0 ° С (0 ° С - the best indicator for household foam on the market) and ambient temperature up to -12 ° С. Original KUDO technologies make it possible to produce household foam, which will work even at lower temperatures, but at the same time, its other characteristics will suffer and the price will increase significantly.

Thus, professional foam, ceteris paribus, provides greater output, less secondary expansion and a wider temperature range of application. At the same time, household foam has a denser structure and better thermal insulation characteristics.

The main criteria for choosing foam

- Ordinary household foam is available in a single use, a tube is attached to the bottle. Typically, such a product does not have a high density, it has a noticeable secondary expansion. Most often, such a composition is purchased to fill gaps and voids, where special accuracy and accuracy are not required.

- For professionals, mounting foam in cylinders is designed for a special gun. The material has a high density, after drying, it retains its original volume, the foam yield is much higher. Thanks to the gun, you can adjust the flow of the insulator, which allows you to economically spend the product. One cylinder can be used several times, washing the gun after each use.

- An important characteristic of polyurethane foam is the temperature range of use. Having bought a summer compound, you can work at a positive temperature from +5 to + 40 ° С. The all-season product has a wider operating range of -10. + 30 ° C. And to seal the seams and fill the voids in the cold, it is better to use the winter version, which can withstand temperatures up to -20 ° C.

- On the spray foam can also be found fire marking. If the product is labeled B1, then the composition is distinguished by refractory qualities. The designation B3 indicates the combustibility of the material. This factor is important to consider when sealing chimneys or heating boilers.

Experts selected in our review the 7 best mounting foams. When making the rating, the following criteria were taken into account:

- safety of use and operation,

- technical specifications,

- price,

- opinion of professionals

- reviews of domestic users.

Rating of the best polyurethane foams

| Nomination | a place | Name of product | price |

| TOP best mounting foams | 1 | Penosil GoldGun 65 | 616 ₽ |

| 2 | Soudal | 365 ₽ | |

| 3 | Makroflex Standart | 350 ₽ | |

| 4 | Titan o2 | 430 ₽ | |

| 5 | Ultima | 176 ₽ | |

| 6 | TechnoNIKOL 65 Constant | 421 ₽ | |

| 7 | Installation moment | 194 ₽ |

Penosil GoldGun 65

Penosil GoldGun 65 polyurethane foam is chosen mainly by professional builders. They celebrate the perfect combination of price and quality of an Estonian product. Experts also note the lack of shrinkage and slight re-expansion, which makes the composition predictable. The foam has earned special praise from experts for the highest possible yield. The material finds a wide scope of application, starting with the installation of window and door frames and ending with filling all kinds of voids.

According to experts, Penosil GoldGun 65 polyurethane foam deserves the highest rating for its high quality, reasonable price, invariably white color and record output in volume. Foam can be criticized only for fear of low temperatures.

How to choose a mounting foam

The choice of mounting foam depends primarily on the conditions in which it will be sprayed and used. For domestic use, a universal option is suitable. For fire hazardous premises, all materials used, including insulating materials, must be fire resistant. And to install the frame in the cold, you need to decide which winter mounting foam for windows is better, and check the range of its operating temperatures.

When reviewing the proposals of building stores, the characteristics of the finished mass, user reviews, and opinions of professionals were studied. When comparing materials and adding them to the TOP best, the following criteria were taken into account:

- Performance and output volume,

- Ease of application

- Operating temperature range,

- The quality of heat and sound insulation properties,

- Degree of secondary expansion,

- Uniformity and density of texture,

- Value for money,

- The ability to buy in popular stores,

- Level of purchase.

For a residential user, the availability of an applicator is also important, and the ability to use a cylinder with a gun will be more important for professionals.

1. One-component and two-component polyurethane foam - what is the difference?

Polyurethane foam or polyurethane foam sealant is a mixture of two chemical substances (polyol and isocyanate), which are obtained from crude oil. As a result of the reaction of these components with each other, pure polyurethane foam is formed, which is the basis of the foam after the completion of the crystallization process. To improve the properties of the material, various catalysts and adhesion promoters, refractory additives, antifreeze components and filler gases are often added to the composition. Due to the porous structure of hardened polyurethane, the foam serves as an excellent insulator. It can be applied to a variety of surfaces by material - stone, concrete, iron, wood, plastic. Such a wide range of compatibility allows solving a lot of construction issues. Depending on the chemical composition Distinguish between one and two component foam.

- For the most part, all the variety of this material presented on the windows is single component. Packed such a composition in a container. The main disadvantage is a short shelf life due to the possible occurrence of uncontrolled reactions inside the container and a long curing period. It will take about a day for complete solidification. The principle of its operation is very simple - at the exit from the cylinder, the composition enters into a chemical reaction with moisture, which is contained in the ambient air, instantly increases in volume and after the above time completely hardens. The foaming agent is a mixture of liquefied gases - a propellant, which consists of butane, isobutane and propane. The same mixture promotes the formation of pressure inside the cylinder, due to which the foam escapes through the nozzle. Upon contact with air, expansion occurs in a 20-40-fold size, which allows filling even the most inaccessible places with high quality and without the formation of internal cavities.

- Two-component polyurethane foam is more complex and costly to operate. The difficulty is that immediately before use you will have to mix several forming components with your own hands, which are stored separately in special containers. In this case, it is very important to strictly adhere to certain proportions, otherwise the resulting mixture will not have the necessary characteristics. The chemical reaction that forms when mixed is dispensed with without the participation of air from the environment and is much faster. Additional costs will be associated with the need to purchase a special mixing gun or a gun installation in which the composition will be prepared. Her main honors from a single component material is the curing rate. The process of complete crystallization takes only 20-30 minutes, and excess material can be cut off after 10 minutes after application. Also, the process of polymerization of a two-component foam does not depend on an indicator of air humidity and always passes successfully. Shelf life is also increased due to the separate content of the forming substances. However, the prepared mixture is not suitable for repeated use and implies the complete consumption of the cylinder after preparation.

So, summarize. The use of two-component compounds makes sense only to professional workers in the field of construction and repairs. For a one-time use at home, a container of one-component foam is sufficient. Even a person who has never used this material before can use foam in a bottle with a nozzle in the form of a plastic tube.

2. Key Features

Like any building material, polyurethane foam has a number of characteristics, the quality of the product depends on the indicator of which. All highlights will be indicated on the label. So what is it worth pay attention when buying:

- The degree of primary expansion is an indicator of how many times the volume of foam at the outlet of the cylinder will increase in contact with air.

- The degree of secondary expansion is an indicator of the increase in the volume of material after the expiration of the period of complete crystallization.

- The density of the foam. It affects the rate of expansion. In household foam, this figure is lower than in professional. To obtain a very tight joint, it is necessary to purchase foam with a low rate of secondary expansion.

- Viscosity is a property of the material, which ensures the non-flowability of the foam on the surface.

- Shrinkage - is indicated in percent and implies a decrease in the final volume of the composition by the specified value.

- The output volume of the foam. On each cylinder you can see the numbers - “50”, “60”, “70”. What do they mean? This is the number of liters of foam obtained at the outlet of the cylinder. But the indicated quantity can only be obtained under condition of operation under the correct temperature conditions and controlled humidity parameters. Usually the actual amount of foam will be less.

- Adhesion to materials - in other words, the ability of the composition to “stick” to various surfaces.

- The time of complete hardening and trimming - given these indicators, you can have an idea of the time it will take to carry out the work, and you will understand how many hours you can plaster, grind or lend the seam to other influences without harm to it.

- The weight of the cylinder is a very important indicator. Keep in mind that if the volume indicated is 750 ml, then it should weigh at least 850-920 grams. If it is lighter, then the composition inside is much smaller than stated. This can often be found with unscrupulous manufacturers. For clarity, you can hold in your hands cylinders of different brands with the same volume. It is possible that one of them will be clearly harder. It is worth buying.

3. Which foam is better, household or professional

It is very simple to distinguish between household and professional polyurethane foam. Just look at the container - if a nozzle in the form of a thin plastic tube is attached to it, it means that it is intended for domestic use. However, it is unequivocal to say that only beginners use such foam, and professionals must use a nozzle in the form of a gun, it is impossible. Consider the maindifferences to help you decide and choose the right view.

- The first thing that is immediately noticeable is the amount of packaging. Household foam is sold in containers with a capacity of 300 ml and above, while professional foam - from 750 ml and above.

- An important indicator is the exit of foam from the cylinder. In the case of household aerosol, not all of the composition can be completely blown out. Usually, some part remains inside, and from the volume declared by the manufacturer you get a slightly averaged value. Thus, instead of the required one cylinder, two may be required, and this already affects the costs associated with the repair. In this regard, professional foam, which is blown almost completely, proved to be much better.

- The secondary expansion coefficient in household compounds is very large. In the process of final hardening, they can increase in volume up to two times. The same coefficient for professional foam is almost zero. For better or worse, depends on the nature of the work performed. For example, if you are faced with the task of filling a large gap in the wall or eliminating the creaks of an old wooden floor by blowing foam under it, a significant expansion indicator in this case is a plus. If you yourself install slopes, plastic windows or doors, then filling the space around them is better with the composition with the lowest coefficient of expansion. Otherwise, there is a possibility of surface deformation. Only with proper skills in working with this material can household foam be used for such precise work. Usually, specialists fill only 1/3 of the gaps with foam, knowing that they have finally hardened, it will fill the entire space without changing the geometry of the adjacent surfaces.

- The shrinkage rate of household foam is 5-7%. Professional - 0-3%.

- Regarding the need to use an additional device in the form of a mounting gun, household foam wins, of course. It is enough to wind the tube supplied in the kit, shake well, and the foam is ready for use. Professional compositions work only with a pistol, the cost of which is several times higher than the cost of the foam bottle itself. For single use at home, such expenses are impractical. Indeed, in addition to this, it will be necessary to purchase a special solvent that will clean the nozzle of the gun from the remnants of the foam.

- The possibility of reusable use is undesirable for household cylinders, but possible. If it was not possible to use the entire cylinder to the end, clean the remaining cavity of the tube from the remaining foam with a propellant and store in a cool, dark place. Professional foam can be used partially. But it is necessary to store it at the same time with a pistol dressed on a cylinder. In this case, the foam inside does not harden and is suitable for further use. The nozzle of the gun must be cleaned with a special solvent.

- And the most main difference - the nature of the work performed. Household foam is used for one-time, rough work, which does not require accurate dosage. Professional compositions are distinguished by the possibility of high-precision application and are used for sealing joints or thermal insulation.

4. What is “summer”, “winter” and “all-weather” polyurethane foam?

One of important parameters polyurethane foam, about which I would like to say separately, is temperature mode of operation. Be sure to take into account the temperature in the room and beyond before buying polyurethane foam. It is not in vain that this parameter is indicated on cylinders. Following the recommendations of the manufacturer, it is possible to achieve better quality of the material obtained at certain times of the year. Distinguish three kinds assembly foam:

- Summer - used at temperatures from 5 to 35 ° C. It is usually used for repair work inside or outside the premises in the warm season.

- Winter - the range of operating temperatures is -10-35 ° С.

- All-weather foam - used at ambient temperatures from -10 ° C to + 35 ° C.

Why is that important to comply are these conditions? Because the use, for example, of summer foam at sub-zero temperatures will affect the duration of its full hardening, the density of the resulting weld, the expansion coefficient and the volume of foam at the exit. All these indicators will differ significantly from those stated on the label, and the quality of the work performed will noticeably worsen. Complete crystallization time will increase significantly. The same will happen if winter foam is used during the hot season.

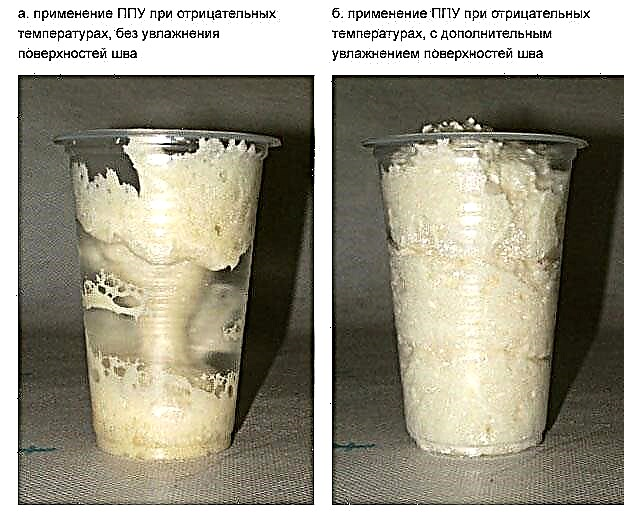

Regarding all-weather foam - important nuance its use is the temperature of a cylinder of liquid. Yes, the range of operating temperature allows the use of foam at minus indicators, but professionals recommend heating the aerosol to a temperature of + 10 ° C. In this case, the characteristics of the material will be much higher.

5. How to use the mounting foam

Consider situations when appropriate and when not really, use assembly foam:

- Do not use foam for sealing cracks with a width of less than 1 cm. For these purposes, sealants or more plastic materials, such as putty, are better suited. In addition, these materials do not have secondary expansion.

- If the width of the gap exceeds the mark of 10 cm, before filling it with mounting foam, it is better to further reduce the space using wooden beams, bricks or any other sealant. This will significantly reduce the consumption of foam and increase its adhesion to the surface. Otherwise, under its own weight, it can simply slide along the walls of slits of large width.

- The optimal size of the gaps for filling with mounting foam is 2-8 cm.

- For faster polymerization and better adhesion of the foam to the adjacent surface, many recommend slightly moistening the walls before application. And then, spray the installation joint with water from the spray gun after the initial hardening.

- It is not recommended to use foam on surfaces such as Teflon, silicone, polyethylene and other greasy or dusty walls. She just does not stick to such materials.

- Be sure to consider the coefficients of primary and secondary expansion. This will help to understand how thick the seam is to be placed in the gap of a certain width.

- Before using the canister, be sure to clean the surface according to the instructions on the packaging.

- If the bottle is too cold or you brought it in from frost, hold it in warm water (not more than 20 ° С).

- To ensure the best mixing of the components among themselves, turn the container upright and shake for 1 minute.

- Use protective gloves. It’s very difficult to wash dried foam.

- In no case do not touch the freshly applied foam until it has frozen. You will not only get dirty, but also disrupt the structure of the material. This can lead to poor hardening or incomplete expansion.

- To get the full amount of foam out of the bottle, be sure to hold it vertically and upside down until the work is completed.

- The mounting foam should be pale yellow throughout its life. But you can see that over time it can darken. This is caused by the harmful effects of ultraviolet rays, which destroy the structure. If possible, it is better to plaster or paint the seams, thereby protecting from sunlight.

It is very simple to use a cylinder with household foam. It is enough to wind the tube and the working nozzle is ready. But if you still decide to purchase professional foam and special gun you need to be able to to use correctly. The principle of its operation is very simple - the gun is wound on a cylinder, after which the foam enters the barrel through the supply valve. There she stays until you pull the trigger. After that, the material is released with a given volume. Consider basic moments:

- Choose guns that are made only of hard metal.

- To facilitate cleaning and replacement of parts, it is better to purchase collapsible than monolithic models.

- Obtain a special cleaner immediately.

- Before installing the gun on the cylinder, you need to unscrew the mounting screw, grease the socket with technical petroleum jelly and only after that proceed with its fastening.

- First you need to set the adjustment unit to the minimum indicator of foam consumption.

- Turn the bottle over and do a couple of test presses. So you can visually assess the need to increase the feed and adjust the volume to your needs.

- Make sure that the cylinder is always upright during operation.

- Upon completion of work or when replacing the cylinder, be sure to thoroughly clean the gun.

Adhering to these key recommendations, you can easily cope with the use of any type of polyurethane foam.

6. Briefly about manufacturers

The key to high quality material is the choice of a reliable and trusted manufacturer. It is no secret that the cost of a product can say a lot about its properties, because it will not be possible to make a high-quality product from cheap components. But also overpriced not always associated with the use of quality raw materials. Often, too hyped brands spend a lot of money on advertising a product, which automatically increases its price, and you just get a brighter and more memorable package, rather than higher technical specifications than a less expensive product. Therefore consider proven brands with not overpriced:

- Macroflex - has a high rate of adhesion and uniformity of structure. The foam output stated on the packaging is true. However, in recent years there have been many fakes, which has led to numerous complaints about the deterioration of the quality of the goods. The cost, depending on the type of foam, is 150-470 rubles.

- "Moment Installation" - differs in a dense and uniform structure, is well painted, is quite common in a network of construction stores. It has a large indicator of secondary expansion, and after a couple of years it can lose elasticity. The price is 145-245 rubles.

- "Sudal" - a very high-quality product with a fine-grained structure. Differs in the absence of shrinkage. Available in several versions - winter, summer and fire resistant. Has a mild odor. But it is not sold everywhere. Cost - 195-395 rubles.

- "Penosil" - It has a good rate of foam exit from the cylinder, it has a bright white color and a low secondary expansion coefficient. Not intended for outdoor use. At a temperature of more than + 35 °, it ceases to foam. Price - 200-485 rubles.

- "Titanium" - has a dense structure, lack of shrinkage and a small indicator of secondary expansion. It is used for thermal insulation of heating systems and water supply. The foam yield can be defined as medium, not complete. The price varies from 200 to 265 rubles.

7. What to look for when buying

Of course, you will not be able to evaluate the quality of the material directly in the store, but there are several signs which will help you choose a really high-quality product:

- Pay attention to the packaging, or rather its condition. There should be no scratches, dents, nicks or other mechanical damage on the container. Their presence indicates improper storage, which will necessarily affect the final result, or negligent transportation, which indicates the unreliability of the manufacturer.

- Be sure to check the expiration date of the composition. The “fresher” the date, the better the substance possesses.

- Turn the bottle up and down several times or shake it lightly. You should feel how the fluid inside rolls easily and quickly. If it seems that the components are “falling” to the bottom of the container, then the curing process has begun. Mix as it should, such a foam will not work.

- The weight of the cylinder according to your sensations should exceed the volume stated on the package. A 500 ml bottle should not weigh exactly 0.5 kg. This means that there is much less liquid inside, and at the exit you will get fewer liters of finished foam.

So fast visual inspection it will already say a lot about the product that you are holding in your hands and will protect it from fakes.

What is the difference between professional foam and household?

In everyday life, a tool related to household categories. And the price is much lower. Take, for example, the “household chainsaw”. Few people use it more than once a month, respectively, it makes no sense to purchase an expensive professional tool, it is unlikely to pay off. And among these products you can choose a quality option, which is even more convenient to use. Simply, he will have less motor resources and work breaks will have to be done more often.

When it comes to polyurethane foam, dividing into categories is for the most part only a clever move invented by marketers. And its only result often becomes that we buy a low-quality product. It will be considered a serious mistake that professional foam is intended only for professional builders, and anyone with no skills will be able to work with a household cylinder.

Manufacturers have been able to find a great way to divert buyers' attention from the content, focusing on the method of application. By definition, household foam is a disposable spray can, equipped with a special tube. It is enough to attach the tube to the valve, and the tool is ready for use. Even if we didn’t use all the content to do the job, there’s no point in saving the spray can for the future. Foam quickly polymerizes, blocking the tube opening, which makes the cylinder unusable.

The difference between the professional version, as is commonly believed, is that to work with it requires the presence of a mounting gun screwed onto the valve. Since the gun and valve are easily washed with solvent, such a cylinder is reusable. As experience shows, it is often easier for an ordinary person to cope precisely with the professional version, and with a household one and a master with experience will not always provide high-quality work.

When savings turn into extra expenses

The gun allows you to get a smooth stream, and the polyurethane foam will lie down as necessary, no thickenings, etc. A household spray can is much more difficult to use - thickening, tubercles, waves are guaranteed. And the material will go much more. Moreover, practice shows that where a professional cylinder foam would need one cylinder, three household ones will go.

Worse, the contents of the “household version” are sometimes of completely unacceptable quality. As a result, we get an extremely porous, heterogeneous polyurethane, which softens or crumbles in a year.

There is no need to talk about savings. It turns out that it is much more profitable to buy a gun for polyurethane foam, especially since you can find quality options that are quite affordable. One caveat, it is better to give preference to models, most of the parts in which are metal. It is also important that he understands the maximum number of elements, so it is easier to clean from foam.

What else to look for when buying

How to choose a mounting foam, so you don’t regret your decision? We have already considered one criterion and proved that it is worth acquiring a version that has a valve for the gun. But to make sure the quality of the content is impossible until you start working. It is very rare in stores to allow you to experience the cylinder. Therefore, we have to analyze other points:

- Weight. Of course, you won’t check the quality, but you can make sure that you are not being deceived with the volume. Take in different hands the cylinders of various companies and compare. The result can be very surprising.

- Particular attention should be paid to the country of production. It is better not to buy Chinese foam if you do not want to throw money away. The quality of products manufactured in Germany, Poland, the Czech Republic, France and Estonia is much higher. Recently, the quality indicators of products of domestic manufacturers are also improving. Robi-Foam polyurethane foam is among the leaders

The main characteristics of high-quality polyurethane foam

In fact, polyurethane foam appeared on the construction market not so long ago. Therefore, we only learn to distinguish quality foam, and that is mainly by trial and error. But some points can already be characterized:

- Any polyurethane foam does not tolerate sunlight. It is possible to eliminate this drawback by painting or plastering it. At the same time, poor-quality material is subject to the negative effects of moisture and temperature extremes, and plaster does not save here.

- Quality foam has a minimum shrinkage of not more than 5%. The cause of the shrinkage is the drop in internal pressure that occurs after the polymerization of the foam. When it is excessive, the density of joints will decrease and even tears in the seams are possible. If this happens, then you can’t do without a complete alteration of the work.

- Professional foam has a dense structure with minimal bubbles, no shells. To check this, just make an incision on the finished material.

- A significant role is played by the expansion coefficient. It is customary to distinguish two stages of expansion: the first is observed when the polymer is in contact with moisture and air, the second lasts from the moment the bulk is formed until it completely hardens. The difference between high-quality material and fake is the presence of a clear expansion coefficient. It may not be large (and sometimes it should not), but stable - it is necessary.

- Volume will also help determine the level of quality of the foam. Here you should take into account the temperature in the room or on the street. With its decrease, the volume will decrease and this is normal. For the cold season, there is a special foam, which even in winter will provide the specified amount of substance. But, when in warm time the volume of the spray can not reach the norm, you can be sure that this is a fake.

Summing up, it should be noted that under the professional polyurethane foam should be understood only high-quality material, while the method of application does not play a role. No one is safe from fakes, but still, most often, those who buy the household version run the risk of encountering them.

Macroflex

Macroflex from the Estonian manufacturer Henkel is included in the best all-season mounting foams with a one-component composition based on polyurethane foam. It combines an affordable price and good product properties, which is why it is loved by professional builders. The output is up to 65 liters of material. The solidification period is 24 hours, during which time the mass turns into a durable aggregate, which is resistant to mechanical damage.

The cylinder is equipped with a temperature indicator showing whether it is possible to apply the material under these conditions or not. In addition to a standard 750 ml bottle, the manufacturer offers 300 or 500 ml options for closing small local gaps. Macroflex is sold complete with an applicator tube.

Advantages:

- Simple application

- Bonding to most surfaces,

- Fills the cavity evenly

- Non toxic

- Good insulating properties.

Disadvantages:

- Afraid of the sun,

- The cylinder immediately needs to be used in its entirety.

The final output volume of the material depends on the conditions and technique of its application. Low humidity will not allow it to fully expand, and the incorrect position of the cylinder reduces its throughput.

TechnoNIKOL No. 800 Master

Reviews about TechnoNIKOL polyurethane foam are mostly positive. It was developed by a Russian manufacturer for domestic use in various weather conditions. The sustained temperature range is wide - from -10 to +35 degrees. The material is sold in 800 ml cylinders, the output of which reaches 60 liters of finished insulation material. Tack-off time is only 15 minutes, and full polymerization is 24 hours. The mass freezes under the influence of moisture.

Advantages:

- High penetration

- Even distribution without jerking,

- Dense homogeneous texture after drying,

- Manufacturer Reputation.

Disadvantages:

- At low temperature it may bubble.

The cylinder must be stored exclusively vertically, otherwise the composition loses some of its properties.

Titanium O2

The best universal mounting foam for a gun from those presented in this rating. The one-component formula expands well when applied to the surface. It is intended for professional use. High performance (65 liters from a 750 ml bottle) is achieved thanks to an innovative formula.

The composition is characterized by a high level of adhesion to concrete, brick, glass, gypsum, wood surfaces. The foam does not contain CFC and HCFC, making it environmentally friendly.

Advantages:

- Economical consumption

- Low secondary expansion,

- No pungent odor

- High degree of sound and thermal insulation.

Disadvantages:

Titanium O2 is loved by professional builders because it speeds up the work process. Due to express drying, it can be cut off already 25 minutes after application.

Soudal

Professional foam that can be bought at most hardware stores. It has a low expansion and is suitable for thin joints where accuracy of application is especially important.

Soudal has high adhesion not only to brick or concrete, but also to metal or glazed surfaces. The tip is included, so that the cylinder can be used not only with a construction gun.

Advantages:

- Size stability

- Homogeneous texture,

- Ease of application

- Complete protective gloves.

Disadvantages:

Users note in the reviews that there are defective cylinders with a poorly functioning valve.

The best fire resistant foam

Fire-resistant qualities are especially important when applied in rooms with high temperature conditions: baths, factories, restaurants, night clubs and other entertainment venues. Fire retardants added to their composition, giving non-combustible properties to the entire composition. After conducting an analysis of this market segment, 3 leaders were identified who are preferred by professionals.

Nullifire

A renowned manufacturer of fire retardant coatings of excellent quality. Proprietary refractory polyurethane foam is able to restrain the fire in the installation joint for up to 4 hours, prevents the spread of smoke and toxic gases. Product quality is confirmed by a safety certificate.

A mass of 880 ml cylinders is sold, of which 45 liters of finished insulation material are obtained. Universal valve fits under sprayer or gun. It is possible to apply material at a temperature from +5 to +35 degrees. The full load, including the mobility of the joints, the aggregate withstands after 24 hours.

Advantages:

- Promotes good sound insulation

- Suitable for most building surfaces,

- Loses stickiness 10 minutes after application,

- The temperature limit reaches +130 degrees.

Disadvantages:

- Destroys under UV rays

- The price is above average.

For maximum effectiveness, foam is recommended to be used with manufacturer sealants.

Rush Firestop Flex 65

Professional installation material with refractory qualities, which you can buy at an affordable cost. It ideally fills joints of any thickness, has a low level of expansion during hardening and expansion of the material. The shape of the aerosol gives a uniform mass output throughout the use of the entire container.

Up to 65 liters of insulating mass is obtained from a 1 liter cylinder with a pistol, which makes consumption extremely economical. And primary processing is possible after 35 minutes. The composition formula refers to all-weather.

Advantages:

- Moisture resistant

- Operating temperature - from -50 to +90 degrees,

- Affordable price,

- Good adhesion to various materials.

Disadvantages:

- Bubbles when applying a layer thicker than 5 cm,

- Short shelf life (9 months).

For maximum performance, the container should be held strictly vertically upside down and shake it from time to time. In this case, a homogeneous dense material is obtained. In frost, the output will be slightly less than in warm weather.

Remontix PRO 65

Good foam under the gun, corresponding to the flammability class G1 and GOST. It can resist heating for 4 hours, suitable for use in rooms with increased fire safety requirements.

An 850-ml bottle gives up to 65 liters of finished mass. The applicator for application is included for convenient single use at home. When spraying, the mass lays evenly and increases well in volume, making it suitable for filling large voids.

Advantages:

- High-quality result in any weather

- It is well cleaned with flushing liquid,

- Durability,

- It hardens quickly.

Disadvantages:

The material has problems with adhesion to polymer coatings. They must be thoroughly cleaned before application and the air must not be too dry.

The best winter mounting foams

Winter foams are designed for sealing joints at low temperatures, which is important for outdoor construction work in cold weather. In terms of adhesive and insulating properties, they are not inferior to summer materials. We conducted an analysis of 10 winter aggregates sold in construction stores, and selected the 3 best ones.

Penosil Gold Gun 65 Winter

The best polyurethane foam for winter. Its consumption is economical: from a cylinder with a volume of 875 ml, 65 l of the finished mass is obtained. The spray temperature of the product is from -18 to +30 degrees. Neither in the cold nor in the heat does it spread during application.

The composition has strong adhesion to almost any surface. It is not necessary to wet the material, since the Penosil Gold Gun hardens well in any humidity. All material leaves the container without leaving anything in the package.

Advantages:

- Quick hardening,

- Moderate secondary expansion (15%),

- Uniform structure

- Eco-friendly composition

- Low cost.

Disadvantages:

When applying the mass in cold weather, it must be borne in mind that the container itself must be warm.

Irfix STD Winter

Inexpensive winter polyurethane foam with a temperature of application from -10 to +30. It has adhesion to all common building materials. From a 750 ml bottle, 60 liters of finished aggregate are obtained. Complete solidification of the mass occurs in just 6-16 hours, depending on weather conditions. After which it becomes resistant to mechanical damage and temperature changes.

Advantages:

- Complete applicator

- Resistance to aging

- Uniform expansion,

- Low price,

- Easy to paint.

Disadvantages:

Before use at minus temperature, the cylinder must be kept for 12 hours at a temperature of + 20-25 degrees. It is recommended to apply the mass from the bottom up, filling it with no more than 40% of the seam.

Makroflex Winter Pro

The most popular option for winter. It can be applied to almost any surface at temperatures up to -10 degrees. During expansion, the mass exerts low pressure on the surrounding structure, which allows you to work with brittle materials, such as drywall. The mass is sold in 750 ml cylinders with a yield of up to 65 liters.

Advantages:

- Extended shelf life

- Manufacturer reputation

- It dries quickly

- Suitable for filling large spaces,

- Excellent insulating properties.

Disadvantages:

There is no application tube in the kit, the bottle is intended only for use with a construction gun.

What polyurethane foam is better to buy

To decide which mounting foam is best, you need to understand which surface and under what conditions it will be applied. When working with fragile structures, you need to pay attention to the level of secondary expansion, and when spraying in frost, you need to make sure the wide working temperature range of the material.

Among the universal joint fillers, the leaders are:

- Macroflex is the best all-season foam at an affordable price. A complete applicator tube, a large selection of cylinder volume and good mass properties make it popular among builders and lay people doing repairs on their own,

- TechnoNIKOL No. 800 Master is the cheapest option in the ranking. It is good at various temperature conditions and is not inferior in quality to more expensive analogues,

- Titanium O2 - foam under the gun with a high level of performance. From a 750-ml bottle, 65 liters of finished mass are obtained,

- Soudal is the best placeholder for thin joints or places where you need accurate application.

For commercial facilities, refractory materials must be used. Foam is no exception. Among fire resistant aggregates, the best are:

- Nullifire - insulating aggregate that inhibits the spread of smoke and fire for 4 hours at the junction,

- Rush Firestop Flex 65 is suitable for filling joints of any size, differs from other fire-resistant options at a low price,

- Remontix PRO 65 is the best option for a gun for professional use in rooms with increased fire safety requirements.

The TOP mounting foams for winter include:

- Penosil Gold Gun 65 - material with the lowest atomization temperature up to -18 degrees without loss of mass quality,

- Irfix STD is the fastest setting material. Full hardening takes place in just 6-16 hours,

- Makroflex Winter Pro is the best option for working at low temperatures. High productivity, uniform application and expansion speak in favor of its purchase.

Having studied the TOP-10, each builder or layman will understand the advantages and disadvantages of insulation materials from different manufacturers and will be able to choose a suitable option for himself among universal, refractory or winter mounting foams.