Parquet lacquer is a chemical compound that covers a wooden floor, upon drying of which a film is formed. This film protects the parquet from chemical and mechanical influences, moisture, etc. Simply put, parquet varnish should preserve the sophistication and appearance of your wooden floor for more than one year. And for this you need to choose it correctly.

How to choose a varnish for parquet?

Whether you choose a varnish for your floor yourself or trust the masters, it is nevertheless important to be knowledgeable in this matter. You need to know what parquet varnishes are, and under what conditions they can be used.

First of all, when choosing a varnish, the purpose of the room and the approximate load on the base are taken into account. If this is an office room, a corridor, a wooden staircase or other passageways that will experience intense loads, a varnish with good abrasion resistance should be selected and at least three layers of varnish should be applied. If this is a bedroom in which you will only spend the night and in which you will not expect a large crowd of people, you can choose the appropriate varnish with a small load on the floor.

The main characteristics and properties of varnishes that you need to pay attention to:

- Abrasion - the ability of a varnish to withstand mechanical abrasive loads from furniture and shoes.

- Elasticity - the ability to maintain the integrity of the varnish film (without cracks) during impacts.

- Resistance to moisture - the ability to protect a tree from water and water vapor, namely from moisture absorption.

- Resistance to chemicals - the resistance of varnish to chemicals (fat, acid, alkali).

- Ecological purity - the absence of harmful substances.

- Optical properties - matte, semi-glossy, glossy, wood tonality change (set fire).

- Spreading - the property of varnish to spread, while forming a perfectly smooth surface.

- Drying time - calculated for grinding between layers.

- The set time is the time before the expiration, which should not be loaded wooden floor.

- Climatic requirements - the temperature of the varnish and the room in which the application will take place, humidity.

- Application requirements - cleanliness of the varnished surface, lack of dust and dirt.

The main types of varnishes for parquet:

• water-based varnish (aqueous polyurethane varnish),

• polyurethane varnish on solvents,

• parquet varnishes of acid curing,

• priming varnish.

Let's look at each type of varnish and compare the pros and cons of each.

Water-based varnish (water-based polyurethane varnish) - In recent years, it has been very popular among not only SUVs, but also for parquet owners. This, first of all, is connected with its advantages and advantages.

The composition of the varnish does not contain a large amount of solvent, but the basis of the varnish is still water. It then starts to evaporate first, but the solvent evaporates much more slowly and its concentration gradually increases. When water does not remain in the dispersion, the solvent begins to absorb the binder and also evaporates.

According to the solvent content, aqueous varnishes are divided into:

• without solvent

• with a low solvent content - not more than 5%,

• with a high solvent content - not more than 15%.

The advantages of waterborne varnish are:

• the highest abrasion resistance among competitors,

• it is possible to apply several layers of varnish in one day, which is very important to prevent downtime among parquet floorers and is good for customers who can quickly move into housing and enjoy their parquet,

• the smell of varnish is neutral, which makes it possible to work even when there are people in the room who are not involved in the process,

• varnish is not subject to fire,

• ecologically pure,

• has high adhesion to wooden surfaces,

• high elasticity and good flowability.

The disadvantages of water-based varnish are:

• sensitive to changes in humidity and temperature in your home,

• raise pile of wood,

• to protect the varnish coating requires special care products,

• are applied exclusively with a 4 mm pile roller.

Analyzing sales, we can say that in the percentage ratio water varnishes today make up 73% of the total mass, polyurethane varnishes on solvents - 17%, the rest varnishes - 10%. We can say with confidence that with proper care of the varnish, water-based varnishes are by far one of the best alternatives in the market of parquet chemistry. Waterborne polyurethane varnishes can save your parquet from many troubles.

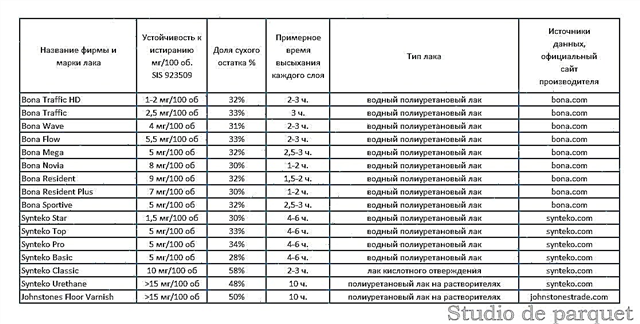

Below is a table with the main characteristics of popular water-based varnishes. Pay particular attention to the wear resistance of waterborne varnishes obtained by the manufacturer’s experimental tests according to SIS 923509. The tests are carried out as follows, on the varnished surface, rotate the abrasive rollers and measure the amount of varnish dust that has peeled off. Less than mg / 100 vol. exfoliates, the more durable is the varnish. The test simulates the actual conditions of use of the varnish, human walking "shuffling legs."

As you can see from the table, water-based varnishes from Bona and Synteko are significantly superior to solvent-based polyurethane varnishes and acid-cured varnishes in abrasion. Other brands did not provide abrasion data (according to SIS 923509) for their varnishes.  The manufacturer Bon with humor declares the quality of his products.

The manufacturer Bon with humor declares the quality of his products.

Solvent polyurethane varnishes - the most resistant to moisture and chemicals. Faster than "competitors" gain their final strength. The basis for polyurethane varnishes can be: urethane, acrylic or solvents. Inherent in the gluing effect of the side faces of the parquet flooring, thus polyurethane varnishes are not suitable for massive boards and large-sized parquet. Also, varnishes on solvents “set fire” (yellowing the wood) some light wood species, such as maple and pine. Polyurethane varnishes can be one-component (PUR-varnishes) and two-component (DD-varnishes).

The advantage of polyurethane varnishes is:

• do not require special humidity conditions during application,

• dry quickly

• resistant to chemical influences.

• preliminary priming of a parquet is not required,

• elastic.

The disadvantages of such varnishes include:

• bonding the side walls of the dies,

• difficult to grind,

• give yellowing to some species of wood.

Acid Cured Parquet Varnishes - have good chemical and water resistance. Hardening of the varnish occurs under the influence of acid. The varnish may contain organic (formaldehyde resins SN-varnishes) and inorganic acids (hydrochloric acid).

Acid-cured varnishes are one-and two-component. Two-component are mixed with a hardener in a proportion of 1:10. After which the polycondensation reaction begins, during which the solvent evaporates from the varnish film. Formaldehyde resins are harmful to the body, therefore varnishing should be done in a respirator and with windows open.

Pros of Acid Curable Varnishes:

• quickly gain final strength,

• do not require special indoor conditions, applicable to restaurants,

• economical

• have good adhesion to wood,

• easy to apply with a roller, brush or spatula.

The disadvantages of such varnishes are:

• contain in their composition harmful to the human body,

• difficult to grind,

• strongly stick together the ends of the dies,

• not elastic

• have an unpleasant smell,

• turn yellow over time.

Primer varnishes - used for finishing varnishes in order to improve the quality of the coating. And also improve the adhesion of the finish varnish with wood. Priming varnish reduces the consumption of the finish by reducing its penetration and flow between the dies. The primer dries very quickly from 15 minutes to 3 hours.

Apply when necessary:

• prevent water residue from entering the surface of the parquet,

• prevent bonding of the side faces of the dies,

• get an even shade across the entire floor plane,

• insulate exotic wood oils.

Keep in mind that some primers and finishes are not compatible, as they have different compositions and different solvents. For water-based varnishes, a water-dispersion primer should be used. Even better if they are from the same manufacturer and their compatibility will be confirmed by the data of this manufacturer.

Varnish care

Observing many customers, we noticed a tendency that those who are meticulously related to the final result, seek out the slightest flaws in the coating, lose their interest in varnish after putting the parquet into operation. Instead, it would be appropriate to take care of the coating. The use of parquet varnish care products can extend their life by 25%. Below is a short video on the care of varnish from Bona.

The following cleaning and care products are available:

• for piece parquet varnished. This includes primary protection and permanent care and removal of heavy contaminants.

• for a parquet board and finished parquet. In this case, means are used to protect the joints, constant care and removal of contaminants.

• for parquet with oil-wax coating. Means for regular care and removal of pollution.

To summarize

As a result, we can say that not one of the varnishes existing today can be applied in all cases. Absolutely universal varnish coating does not exist today. Each specific varnish is created with the aim of being used in the segment allocated to it. The choice of varnish is carried out for each individual object based on the properties of the varnish, customer requirements, the purpose of the object, the type of flooring and other factors.

For example, water-based varnishes (water-based polyurethane varnishes) will perfectly protect your parquet in the corridor, bedroom, living room and other places with an intense load, but it will be advisable to use solvent-based polyurethane varnishes or acid-cured parquet varnishes in the kitchen. We also recommend entrusting the application of finishing varnish to experienced professionals in order to get high-quality coating without stains, thereby significantly saving on the possible “risks” of attracting parquet amateurs.

Features

Water-based varnish is a type of paint product, which is distinguished primarily by environmental friendliness. It contains water and emulsifiers (acrylic or polyurethane). In addition, the composition may contain liquid polymers, antiseptics (in the composition of varnishes for wood processing), solvents (their share can be 5-15%), plasticizers (provide increased strength of the varnish layer). The presence of water is due to the peculiarity of the "setting" of varnish. First of all, it is it that evaporates, then the film-forming component (solvent) and, lastly, the binder component (emulsifier).

All water-based varnishes are divided into two large groups - one-component and two-component. One-component compositions, as the name implies, consist of one active component - acrylic or polyurethane.

- Acrylic the compounds are considered more environmentally friendly, they do not create on the surface of the film, so the bases can "breathe". In addition, acrylic varnishes are more flexible, which means they are easier to apply. However, these compositions do not demonstrate as high strength indicators as polyurethane analogues. The optimal field of application of the product is residential premises with standard environmental conditions.

- Polyurethane Varnishes, characterized by a large margin of safety, are used for surfaces in public and office buildings. They are suitable for substrates subject to high mechanical stress and prone to damage.

The basis of the two-component varnish is acrylic, in which polyurethane is added to improve performance. An important feature of water-based varnishes is their freezing at low air temperatures. After thawing, such a product is not suitable for use.

Compliance with storage rules helps to avoid damage to the composition. Water-based varnishes can only be stored at a positive temperature.

Specifications

Speaking about technical characteristics, it is logical to note the advantages of water-based varnishes.

- Environmental friendlinessdue to the absence or minimal content of solvents and other aggressive chemical elements in the composition. This leads to the absence of an unpleasant odor in the process of staining and drying of water varnish. Neither alkyd, nor oil, nor even formaldehyde composition can demonstrate similar properties.

- High fire safety - the material is completely non-combustible, which allows it to be used on surfaces to which increased fire safety requirements are imposed.

- High drying rate - 3-5 hours after application. However, one should not forget that the final strength of the layer will gain in 15-30 days.

- Good performance adhesion, but subject to compliance with the technology of preparation of working grounds.

- Antiseptic ability It is characteristic for acrylic varnishes.

- Durability to temperature differencesincreased humidity.

- Durability to the influence of ultraviolet raysthat provides reliable protection of surfaces from sunshine, preservation of their color.

- Possibility further use working tools - just wash them with soap or dishwashing detergent, rinse and dry.

- It is important that no bad smell, as well as a high drying rate allow you to carry out work without changing the usual way of life of households. No need to think about where to relocate children and elderly relatives during the repair.

Like any type of varnish, the composition in question has disadvantages, namely:

- lower indicators of strength to mechanical stress compared with similar indicators of other types of varnishes,

- the possibility of application only at a temperature of + 15–20ºС and air humidity of 50–55%,

- high cost in comparison with other types of varnish.

Dispersion varnish with the addition of polyurethane has high moisture resistance, as well as resistance to household chemicals, including alcohol-containing. The interior composition usually has an acrylic base, and for application to the floor - polyurethane, characterized by increased strength. Varieties of the product are also distinguished for different types of substrates (wooden, concrete, drywall and others).

Separately, it is worth highlighting the self-priming composition on a water basis, used for finishing. One of its main advantages is the ability to spread evenly, forming a flat surface. The use of the composition can significantly improve the appearance of the varnished surfaces.

There are such varieties of self-priming composition as:

- glossy - allows you to get elegant shiny surfaces, emphasizes the saturation of bright colors. Not suitable for application to surfaces with defects, as it makes them even more noticeable,

- matte - derivative of alkyd-urethane composition.It does not have a characteristic shine, it looks elegant, noble, and also emphasizes the color depth, visually hides the imperfections of the base.

In addition, there are "intermediate" options - semi-gloss and semi-gloss. The latter exhibits a high degree of brilliance, but still does not “reach out” to pronounced glossy coatings. Water-based varnish is a colorless transparent composition, and when it comes to the acrylic version - a milky white shade. However, when you add color to them, you can get any shade. Transparent varnish does not change the shade and structure of the surface, but only emphasizes them.

Scope of application

The bulk of water-based products are intended for indoor use, their use for exterior decoration is not recommended. The tool has a fairly wide scope. It increases moisture resistance and other operational characteristics of walls, furniture, and interior elements. However, water-based acrylic compositions can not withstand increased static and dynamic loads, therefore, they are unsuitable for application on top of a floor covering with high traffic. It is permissible to use them in the bedroom and the nursery, for example, but not in the living room and hallway. For these rooms, it is better to choose analogues with a polyurethane binding component.

It should be noted that acrylic varnishes and paints are usually used for home decoration, while more durable polyurethane paints are used in surface treatment in public buildings.

Two-component compositions are most often used for applying to wooden flooring. In addition, they can be applied on metal, concrete, stone, drywall. Similar formulations are used when performing the following types of work:

- foundation strengthening - in this case, they act as a kind of adhesive solution, fastening the peeling elements,

- antiseptic treatment - prevents the appearance of mold and fungus on the treated surface,

- surface protection - the processed bases acquire greater strength, including temperature differences, mechanical damage, high humidity,

- surface color saturation - the formed film protects the bases from burning out under the influence of UV rays,

- surface decoration - depending on the type of such varnish can be used as a tinting composition, to add a dull or glossy shine,

- simplified surface care - Protected substrates can be cleaned with a damp cloth without concern.

Manufacturers: review and reviews

The Finnish company is among the leading manufacturers of water-based varnishes Tikkurila. The range is mainly represented by acrylic varnishes, there are both universal compositions and products for walls, floors, furniture. Buyers note a complete lack of smell when working with the product. And also from the experience of some users, it can be concluded that the composition is better to use in rooms facing the non-sunny side.

Trademark varnishes Eurotex, allow not only to protect surfaces and add gloss to them, but also to create an imitation of valuable and expensive wood species (when applying the composition on wood, of course).

Brand leaders are also considered leaders. Loba. This German manufacturer regularly expands the range of varnishes, as well as color schemes for them. The price range is also wide. A large assortment, as a rule, is demonstrated by such authoritative European brands as Vermeister, Pallmann, Berger-Seidle. In addition to special varnishes for different types of surfaces, as well as wooden furniture, walls and floors, there are modifications for baths and saunas. The latter are characterized by increased heat resistance and moisture resistance.

A positive assessment of buyers has products of domestic producers Lacra. High quality, lack of smell (a small specific “aroma” is possible when using polyurethane varnishes), lower cost compared to the price of imported analogues - all these are undoubted advantages of the products. The range is represented mainly by compositions for topcoat. A variety of products boasts company products V33, since it includes options for floors, walls, furniture, as well as universal varnishes. Means amaze with a variety of colors like wenge, stained oak, pine and others.

If necessary, varnishing or decorating furniture, it is recommended to use varnishes 3v3 from the french manufacturer. Due to the characteristic consistency, it is easier to apply them on curved surfaces, to use in hard to reach places.

The increased indicators of wear resistance and durability are characterized by a varnish stain Deluxe. In addition, the tool allows the grounds to give a noble appearance, imitation of valuable wood species. According to reviews, this composition, deposited in the corridor, does not require updating for about 3 years. At the same time, an impeccable appearance of the floor is maintained even in conditions of high traffic and regular wet cleaning.

In the assortment of this manufacturer there is another composition for processing parquet boards - Dulux Trade Diamond Glaze. Due to the composition and production features, this varnish provides 10 times greater strength than other water-based varnishes.

Tips

Experts recommend following a few tips when using water-based varnishes.

- To obtain a flawless result, as well as maintaining the performance of the varnish it is important to prepare the working grounds in advance. They should be even, clean (without grease stains and traces of the previous coating), dry.

- First applied primer. This stage of the work cannot be skipped, the primer should be applied in 2-3 layers, which will reduce the consumption of varnish, and increase the strength of its layer.

- Recommended use special primers intended for the surface being trimmed, for example, for wood surfaces, a wood primer should be used. It is important to choose compatible primers and varnishes. Both must be water based.

- Water-based varnishes are not applied by brush. For this purpose, only a roller is used, on large bases you can use a spray gun. The use of a brush threatens the appearance of noticeable bands on the surface to be varnished, so even in corners and other hard-to-reach areas, rollers of appropriate sizes are used.

- Before applying each subsequent coat, you must wait complete drying of the previous. Otherwise, surface roughness and roughness cannot be avoided. If this recommendation is followed, but the dried varnish layer is rough, then this is due to dust settling on the varnish. You can fix this problem by grinding a defective surface.

- Acrylic and polyurethane varnishes before use is necessary mix thoroughly or shake within 2-8 minutes depending on the volume of the container with varnish.

During use, the composition is also periodically changed every 30-60 minutes.

- Application of water-based varnish is permissible only at a temperature not lower than + 12ºС and not higher than + 30ºС. The experts consider the optimal range to be + 20-23ºС. Failure to comply with this requirement is likely to reduce the adhesive properties of the product. A change in temperature during the drying process of the varnish usually leads to an increase in drying time and curing.

- When staining furniture, it is recommended if possible to make out. This will allow for a better coating of varnish.

- If after mixing the composition seems too thick and inconvenient for application, it is permissible to add water to it, but not more than 10-15% of the total.

- If necessary, tint or update the surface can use color. It must be thoroughly mixed with varnish, otherwise you will not be able to avoid more or less bright colored stripes when painting.

- Tinting waterborne varnish can only be impregnated on a similar basis. First, the test part of the varnish is prepared - a small amount of dye is added in drops. After mixing, if the shade of the composition suits, it is checked on a separate surface area.

- You can tint the base with spray gun or foam swab. This will achieve a more uniform layer. With different thicknesses of the applied layers, the shades in the thicker area will be darker. Experts recommend painting surfaces in 2-3 layers, applying them as thinly as possible.

- By varnishing the plastered walls, previously It is recommended to wax them. This will reduce the consumption of varnish and will allow you to get a noble shimmering surface that changes its appearance depending on the angle of illumination.

- Before applying the top coat of varnish is walk on the surface with sandpaper, and then dedust it. This will avoid the formation of bubbles on the last layer.

- During operation, as well as during the drying period, close the windows. This will prevent dust from settling on the sticky surface.

In the next video you will find a comparative test of water-based varnishes.

Water Based Varnishes: General Information

Water-based varnish or aqualak is a popular paint and varnish material, which is a worthy alternative to alcohol varnishes. This is an environmentally friendly material that has long won the love of ordinary people, especially those who care about their own health and who prefer to surround themselves with environmentally safe things.

This decorative and finishing material consists of natural components, which means it does not have toxic fumes and an unpleasant odor, it is easy to use and protects wooden surfaces from destruction and damage for a long time.

Scuba composition

The composition of water-based varnish also indicates the safety, because the aqualak consists exclusively of water and natural emulsifiers (substances that can create an emulsion from immiscible components).

An emulsifier in such a varnish can be one of two substances:

In addition to the main components, excipients may be present in the composition:

- antiseptics (protecting wood from the appearance of fungus and pests),

- liquid polymers

- plasticizers (thanks to them, varnish gains the necessary strength),

- solvents (their proportion can be from 5 to 15%).

Water-based varnish classification

All scuba diving can be divided into two large groups:

- One component. They are called so because they have in their composition only one active component - acrylic or polyurethane,

- Two-component. The name suggests that in the composition of this paint material there are two polymers at once - acrylic and polyurethane.

One-component varnishes

- Acrylic Varnishes

Most experts call these varnishes the most environmentally friendly among all paints and varnishes. Unlike many other varnishes, this material does not create a dense varnish film on the surface, and this fact allows the tree to “breathe”. It should be noted and the elasticity of acrylic varnishes, which is much higher than that of competitors. This feature makes the application of varnish a simple task, which even a layman will successfully cope with.

At the same time, acrylic varnishes have some disadvantages. Firstly, they are not as durable as their polyurethane counterparts. And secondly, these materials are more suitable for coating surfaces inside the building, while when processing external surfaces they do not demonstrate their best qualities.

The disadvantages of acrylic varnish include the loss of their protective properties at temperatures below -25ºC. In such conditions, the varnish begins to crack, which means it will require restoration in the future. Unstable acrylic varnish and high humidity. In such an uncomfortable environment, it quickly becomes cloudy, bubbles may appear on it, but even worse, it begins to lag behind the base.

Experts agree that waterborne varnishes with an acrylic base behave perfectly in the interior, but are completely unsuitable for facade decoration and outdoor use.

- Polyurethane varnishes

These are extremely durable paints and coatings, which in terms of reliability and ability to withstand external negative influences are many times greater than their acrylic "brothers". No wonder polyurethane varnishes are used for processing internal and external surfaces of administrative buildings and structures.

These materials are able to withstand large mechanical loads, and are resistant to damage. We can say that these varnishes are universal and have a wider scope of application than coatings based on acrylic.

Two-component varnishes

As mentioned above, two active components are immediately present in two-component varnishes. At the same time, acrylic is considered the main one, and polyurethane is added to increase the operational characteristics of the material.

Practice shows that varnishes in which both components are present are the most reliable and wear-resistant, and therefore are used in intensively operated rooms. The surface, protected by two-component material, has additional protection against chemical influences, ingress of alcohol and other liquids, and besides, it perfectly withstands high operational loads (including shock). Moreover, two-component varnishes are resistant to fire, which means they can protect your home from fire! In addition, they do not have an unpleasant odor, which is also a plus when choosing the right material for protecting wood.

Varieties of varnishes in texture

When choosing a varnish, preserving the texture of the wood treated with a protective layer is of great importance. In this regard, scuba diving can be divided into 3 types:

- Glossy varnish. This is a classic version of the varnish coating, which creates an absolutely transparent shiny film on the surface. In addition to the pronounced gloss, the varnish layer is extremely durable and resistant to abrasion. By the way, in addition to transparent glossy varnish, on sale you can find material with shades, for example, golden or silver.

- Matt lacquer. To achieve a noble matte surface, manufacturers mix urethane and alkyd resins. As a result, after application, an opaque thin film is formed on the surface, no less reliable than glossy varnish, but more seasoned and noble.

- Semi-gloss varnish. Semi-matte material is very popular among acrylic varnishes. Perfectly highlighting the structure of wood, this varnish creates a chic unobtrusive shine.

Important! It should be noted that semi-gloss varnish can be applied only on perfectly polished surfaces, because even the smallest flaws under a layer of semi-gloss varnish will be visible in full view.

Benefits of Water Based Varnishes

Scuba competes successfully with alcohol-based coatings, due to several advantages. In this regard, the main advantages of this material include:

- Environmental friendliness. The natural base of scuba gear is a key advantage that other paints cannot boast. In the process of applying and drying, this material does not form toxic fumes, which means that you and your household will be completely safe, both during the entire finishing work and during operation.

- Profitability. By the ratio of price and expense per 1 sq.m This material is superior to many competitors on the surface, which attracts increased customer attention.

- Quick drying. Water-based varnishes dry out quite quickly (no more than 5 hours before complete drying). Moreover, some types of varnish dry in literally 2-3 hours. This feature can significantly save time during repairs, and this is another important advantage.

- Fire resistance. Most coatings are fire hazardous, as they consist of alcohols and resins. But this material, which is 85% water, is not susceptible to combustion and behaves perfectly even near furnaces and portable heaters. Moreover, this varnish can be used as a protective material in rooms with increased fire hazard.

- Durability. The practice of use shows that aqualacs are 1.5 times more durable than alcohol-based coatings. And this fact, taking into account the affordable price of such material, makes water-based varnishes extremely attractive in the eyes of the buyer.

- Reliable protection. Any varnish covers the wooden plane with a protective film. However, the most reliable protection is even an aqualak film. The fact is that the surface tension of this film is not too strong, and therefore it is less prone to cracking and better tolerates mechanical pressure and impacts.

- High adhesion. Due to the high level of adhesion, this material adheres reliably to the working surface, and keeps on it for many years, without departing, without cracking, and without forming chips.

- Antiseptic properties. Water-based acrylic varnish has the ability to resist fungus, bacteria and pests that can damage wood. In connection with this acrylic varnish, it is possible to process surfaces in rooms with high humidity (kitchen, bathroom). But it is better to refuse to process facade details with acrylic varnish.

- UV resistant. Water-based varnishes perfectly tolerate exposure to sunlight. Even with prolonged exposure to the sun, they do not fade, do not become cloudy and do not crack.

Disadvantages of water-based varnishes

- The need to comply with technological conditions. It should be noted that scuba is a whimsical material, the operation of which requires compliance with a number of conditions. In particular, in the room where this material is used, it is necessary to maintain a temperature in the range from -15ºC to + 20ºC. And the humidity level should not go beyond the range of 55-60%. If these conditions are not met, the durability of the water-based varnish will noticeably decrease, it will quickly begin to cloud and the wood under it will darken.

- The need for humidification in the process of applying varnish. To get the most durable surface film, apply water-soluble varnish with an air humidity of around 50%. To achieve this indicator, indoor air will have to be regularly moistened using a spray gun.

- The need to apply multiple layers. To ensure high-quality protection of the wooden surface, water-based varnish should be applied in several layers.

Assessing the pros and cons of this material, many ordinary people agree that the advantages of scuba gear are many times superior to the disadvantages of this material. Thus, if you have to varnish not the largest area, and besides inside the house, water-based varnish should be the material of choice.

Water-based application areas

We list the surfaces and products that are most often treated with water-based varnishes.

- wooden surfaces of the facade of the house or bathhouse, gazebos and other buildings (except for acrylic varnish),

- walls, ceilings indoors

- floors from parquet, laminate or deck board,

- wooden stairs and window frames,

- brick, panel, glass, metal and plastic surfaces, plaster and even wallpaper,

- wooden toys and wooden baby supplies.

How to apply water-soluble varnish

Working with scuba gear is not the most difficult process in technical terms, however it has a number of features that you need to know before applying this paintwork. So:

1. Before you start applying varnish to a wooden surface, it must be prepared. Using thin sandpaper is important to remove the previous coating, whether it be paint or varnish. If you have to work with freshly laid parquet or laminate, it is enough to simply remove surface contaminants and wipe the floor with a damp cloth.

In the presence of defects on a wooden surface (cracks, potholes, dents), they must be puttied and also treated with sandpaper. After waiting for the surface to completely dry, you can proceed to the next step.

2. Before applying varnish, the surface must be primed. Ideally, the primer mixture should have a base similar to varnish (a primer for wood is suitable for the aqualak applied to wood). Naturally, both protective materials must have a water base.

3. The primer mixture needs to dry well, for which it is necessary to wait a day. After the allotted time on a dried surface, you need to walk with a thin emery cloth and remove dust with a vacuum cleaner.

Important! Ideally, a 2-3 coat of primer should be applied to the wall. This will not only strengthen the wall, but also reduce the consumption of varnish.

4. Prepare the necessary tools for varnishing the surface. You will need the scuba gear itself, a roller and a container in which it is convenient to moisten the working tool.

Important! Water-soluble varnishes are not applied by brush. To work with such material, a roller should be used, and if the surfaces are too large - a spray gun. The brush leaves large stains that will be visible to the naked eye. Therefore, even in hard-to-reach places it is better to use the appropriate size rollers.

5. Fill the tray with varnish, and if necessary, mix the components and mix them thoroughly. After wetting the roller in the finished varnish, begin to roll it on the wall.

Important! Please note that the varnish is applied along the wall, and evened across. The movements should be soft and smooth, and the wall should be varnished without gaps.

6. Letting the first layer dry, and this, about 3-4 hours, you can apply the second. According to experts, a reliable varnish coating involves the application of 3-5 layers.

7. Having applied the surface coating, leave it for a week until completely dry. And after that, you can arrange furniture in the room without fear of scratching the lacquered floor.

Popular manufacturers

The market of coatings is replete with the names of companies, each of which is ready to offer its own unique product. We chose the most popular manufacturers, according to customers.

This is a branded product that has long earned the love of customers due to its consistent quality and durability. Especially famous for Tikkurila acrylic water-based varnishes. They are ideal for interior decoration, especially rooms that rarely get sunlight. With prolonged exposure to ultraviolet radiation, such a coating begins to deteriorate. Yes, and its consumption of 12 sq. M. is 1 liter.

Among domestic manufacturers of paint and varnish products, this company is a leader, and all thanks to its versatility, ability to retain moisture, resistance to chemical attack and affordable price. In addition, 1 liter of varnish can cover 17 sq.m. surface. One has only to consider that such a coating is not applied to old layers.

The French company is famous for its top coatings, but the two-component varnishes of this company received special love from customers, because such products have the highest strength and allow you to easily rearrange furniture or gather parties in the house, without fear of damaging the varnished floor. The varnishes of this company are odorless, and their service life exceeds 7 years!

This varnish is made in our country, but from imported components. It boasts a wide range of materials, and their excellent properties. It is enough to say that the scuba divers of this company wash themselves well, do not let water through and do not deteriorate under its influence. In addition, Aqua Parade paints are leaders in drying speed. It takes no more than 30 minutes to completely dry the layer! The disadvantages of this product include only the consumption of 1 liter per 10 square meters, and a high price for a domestic product.

Varnishing wooden surfaces is a common practice. And in order to please your efforts after 5 years, use our tips and choose for yourself only the best water-soluble varnish!