In Western countries, quartz vinyl floor tiles have been used for over forty years. This advanced flooring includes up to 80% quartz sand. The remaining 20% includes vinyl, plasticizers, stabilizers, pigments and a small amount of additives.

In Western countries, quartz vinyl floor tiles have been used for over forty years. This advanced flooring includes up to 80% quartz sand. The remaining 20% includes vinyl, plasticizers, stabilizers, pigments and a small amount of additives.

Each component that is part of quartz vinyl floor tiles performs its functions:

- quartz sand gives the material extraordinary strength, moisture resistance, fire safety,

- plasticizers provide flexibility

- stabilizers protect against light and temperature,

- pigments are responsible for the color scheme,

- additives increase the wear resistance of tiles and help simulate various materials: granite, wood, marble and more.

Laying quartz vinyl tiles is carried out in rooms with a large load on the flooring. It can be heavy traffic of various equipment: cars, loaders. Such premises can be car parks, warehouses, production shops. In office premises, shopping malls, entertainment centers, where there is an intensive movement of people, flooring in the form of quartz vinyl tiles is also used.

Thermal stability of quartz vinyl PVC flooring (range from -40 to +200 degrees) allows its installation both near heating appliances and on unheated loggias and balconies.

Material structure

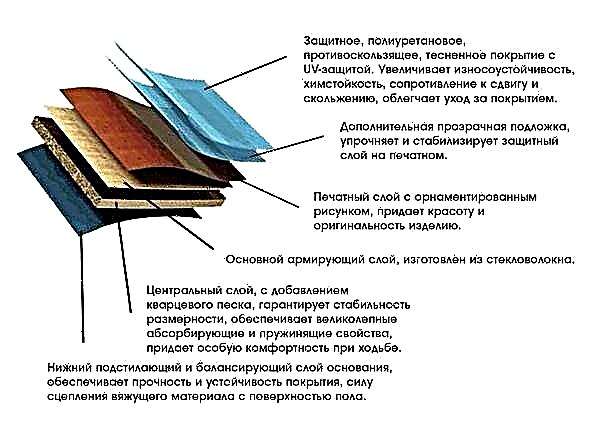

PVC quartz vinyl floor tile is a finishing material, which consists of several layers that are formed into a single unit by hot pressing without the use of chemical additives.

PVC tile design consists of the following layers:

- Top protective, especially durable polyurethane layer. Increases wear resistance, shear resistance and chemical resistance of the floor covering.

- A transparent substrate protects the protective layer from discoloration.

- Printed relief layer with a pattern. This layer gives the product beauty.

- The central layer of quartz vinyl is responsible for the springy and absorbent properties. It guarantees special comfort when driving on the surface.

- This stabilizing and reinforcing layer creates dimensional stability; it is made of fiberglass.

- The bottom layer of PVC base gives the adhesive strength to the floor surface. Provides stability to the floor.

PVC coating structure

PVC coating structure

After finishing the floor you can tackle the walls. One popular option for this is to use plaster. And the technology for applying decorative bark beetle plaster is described in our separate article.

PVC flooring characteristic

The characteristics of quartz vinyl tiles, of course, have their own advantages and disadvantages. The most important The advantages of this material are:

- high wear resistance and flexible tile structure,

- environmental friendliness, no emissions of harmful substances,

- high moisture resistance, the possibility of using this flooring in rooms with high humidity,

- fire safety, the material does not support combustion, it has self-extinguishing properties (applies to classes G2 and G1),

- high resistance to chemical compounds,

- lack of sliding on the top layer of the tile even in the presence of moisture on its surface,

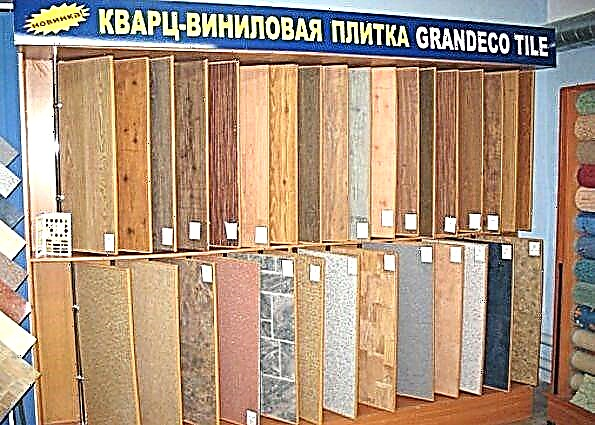

- wide range of colors,

- long service life.

Certain the disadvantages of quartz vinyl tiles can be considered:

- mandatory use of heat and waterproofing layer, otherwise the floor in the room will be cold,

- providing a perfectly even base on which the tile will subsequently be glued,

- laying of quartz vinyl tiles is delayed if it is necessary to do a floor screed.

However, these shortcomings are true for any other type of tile.

How to choose a quartz vinyl tile

In the Russian construction market there is a huge amount of quartz vinyl floor tiles from various manufacturers. Finnish versions of Upofloor are especially popular. No less popular are Armstrong, as well as the British Rikett Flooring and Polyfloor. But the most impeccable and sought-after example of high-quality flooring is quartz vinyl tile from Art Tile. The products of this manufacturer have the highest rates of compliance with all sorts of requirements.

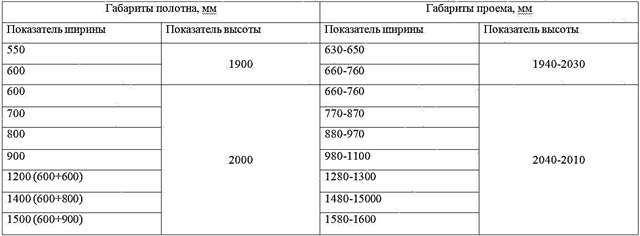

The sizes of square quartz vinyl tiles can be:

Rectangular tiles are:

- 900x150 mm

- 950x184 mm

- 920x180 mm

- 120x148 mm.

The thickness of this flooring is mainly from 1.6 to 3.2 mm.

A variety of color shades of quartz vinyl tiles allows you to translate into reality the most interesting and daring design decisions. Imitation of wooden, marble and ceramic surfaces allows the use of flooring in rooms of various purposes.

Laying Quartz Vinyl Tiles

Quartz vinyl floor tiles can be laid in two ways:

- adhesive bonding method

- glueless joint.

For the latter method, quartz vinyl tile with a lock connection is used. In this case, there is no need to grip the floor with the floor. Tiles are interconnected using a reliable spike groove system. That is, the spike of one tile is inserted into the longitudinal recess of the other, then latched.

Note: Installation of quartz vinyl tiles with a castle connection is easy and simple, even, as well as its dismantling. When moving, you can easily disassemble the structure and take it with you.

For laying ordinary adhesive tiles, acrylic dispersion adhesives, vinyl based on rubber or a special adhesive for quartz vinyl tiles, recommended by the manufacturer of the coating, are used.

What tools are needed:

- marking cord, pencil and tape measure,

- a sharp knife and a metal square,

- adhesive spatula, rubber roller and sponge,

- building level.

Preparatory work before laying quartz vinyl flooring:

- Dismantling the old flooring.

- Mandatory leveling of the surface of the base: repairing cracks and pits with acrylic putty, removing bulges.

- Cleaning the base from debris and dust.

- Coating the base with a water-repellent primer using a roller.

Installation of quartz vinyl coating

Installation of quartz vinyl coatingTile laying steps:

- Marking the starting point from which the styling line is drawn.

- Putting adhesive with a spatula.

- Laying quartz vinyl tiles.

- Rolling the floor with a roller to smooth out the undulation of the adhesive layer.

- Trimming corner and edge tiles.

- Removal of excess adhesive by sponge.

If the floor has large irregularities, then it is necessary to make a screed. And how to make a floor screed, read on our website.

Ways of laying tiles on the floor, if we are talking about its ceramic options, you will find in this material.

Information on what type of underfloor heating to put under the tile is located here.

Additional tips

- The floor covering is mounted only on a dry base (humidity less than 5%).

- The tile must be laid in 5-10 minutes after applying the adhesive to the floor.

- The tile is laid without squeezing and excessive pressure, but always as close to each other as possible.

- A small gap can be left between the tile and the wall, which is then filled with silicone sealant.

- For a reliable fit of the tile to the base, it must be rolled in two directions immediately after laying.

- Prevent air from entering the quartz vinyl flooring.

- As a rule, processing joints after laying tiles is not required. But in rooms with high humidity, it is recommended that the joints be processed by cold welding, but only after the final setting of the glue.

Benefits of Quartz Vinyl

✔100% moisture resistant. Quartz vinyl tile refers to waterproof flooring: moisture absorption coefficient - 0.0001%. Due to this, quartz vinyl does not change geometrical dimensions during operation and can be used in rooms with high humidity and the risk of direct contact with water.

✔43 class of wear resistance.Maximum wear resistance class - an indicator for the use of quartz vinyl coatings in premises of any purpose: from an apartment and a quiet office to shopping centers and terminals.

✔Frost resistance. Quartz vinyl flooring can stack in unheated rooms with one caveat: at low temperatures, the material (due to the content of plasticizers) becomes more brittle and vulnerable to physical stress.

✔Coverage of large areas. Thanks to the minimum coefficient of thermal expansion and compression, it is possible to lay quartz vinyl on areas up to 400 m2 without expansion joints.

✔Lack of smell. High-quality quartz vinyl floor tiles are odorless - neither during installation, nor during operation.

✔A variety of decors. A decorative film is integrated into the structure, onto which a high-resolution image is applied: the texture of wood or stone, parquet, abstractions, ornaments.

✔Compatible with underfloor heating. It is allowed to install a warm floor under quartz vinyl (with a temperature not exceeding 28 ° C), but heating efficiency will be minimal due to poor thermal conductivity flooring. Read more on the combination of quartz vinyl and warm floor.

The disadvantages of quartz vinyl coatings

- Specific styling. Soft PVC tiles require very careful preparation of the substrate: even the smallest flaws are printed on the surface.

- Incompatibility with film floor heating. Infrared heating is difficult to control, there is a risk of overheating. For quartz vinyl tiles, heating above 50 ° C is critical: the coating is deformed and destroyed.

- Fakes. Prices for high quality quartz vinyl - 1500-2800 p. / M2, the middle segment. However, using low-quality raw materials, unscrupulous manufacturers reduce the cost to economy laminate or linoleum. In combination with cheap PVC tiles, there is a risk of allergic reactions, a short-lived floor, a specific smell, and burnout under ultraviolet light.

Salon "Polov" specializes in SPC flooring: the catalog contains the most complete range of stone laminate 43 application classes (for home and office without restrictions) at producer prices!

- The best offer!Refloor Fargo. Thickness 4 / 0.5 mm, no backing, wide format plank at standard price. Free shipping!

- Art Stone. Thickness 6 / 0.5 mm (protective layer PU Diamond), acoustic backing EVA Waffel, wood and stone decors, mix designs.

- Art Stone Airy. Ideal for home: 34 class, thickness 4 / 0.3 mm, no backing, wood decors, MINI trims.

- Floor Factor Classic. Increased wear resistance (double protective layer): 5 / 0.55 mm thick, without backing.

- Alpine Floor Classic and Real Wood. Wood decors, protective treatment Easy Clean. For the Real Wood collection, an Isofix backing is provided. Free shipping!

- Alpine Floor Intense and Expressive. Thickness 6 / 0.55 mm, Isofix substrate, Easy Clean topcoat. Free shipping!

- Vinilam Ceramo. Thickness 4.5 / 0.5 mm, three-component protective layer, IXPE substrate, Ultra Fresh antibacterial treatment, XXL wide-format trims and stone decors.

- Stonewood. Thickness 3.5 / 0.5 mm, no substrate (however, it is allowed to use, despite the small thickness of the plate).

- Aquafloor Quartz. As a mineral - marble powder, thickness 3.5 / 0.5 mm, no substrate, antibacterial CPL protection. Free shipping!

- Aquafloor Art. Imitation of art parquet, thickness 3.5 / 0.5 mm, no backing, CPL protection. Free shipping!

✔ Complete catalog of castle vinyl laminate, adhesive vinyl floor and wicker vinyl. Also for you on an ongoing basis valid shares: "Free delivery in Russia" and "Glue as a gift." Look for promotional items with red tags!

Quartz vinyl tile structure

The structure of quartz vinyl is dominated by quartz sand (calcium carbonate, ordinary chalk). The carrier layer also includes table salt, wood flour, ethylene plasticizer, coniferous resin. Thanks to the correctly selected proportions, the components interact effectively, providing exceptional performance characteristics of quartz vinyl tiles.

- Wear resistant polyurethane layer with UV protection.

- Vinyl protective layer.

- Decorative layer with a pattern.

- Carrier layer made of composite materials and PVC.

- Stabilizing layer (fiberglass).

- Acoustic backing (optional).

Soft PVC tile vs vinyl floor on a rigid SPC / WPC plate

Soft vinyl tiles have excellent technical characteristics, but have one significant drawback: soft structure vulnerable to point damage. That is why PVC tiles can not be laid on tiles, linoleum or boards. It is strongly not recommended to use substrates. Only perfectly smooth concrete screed and obligatory gluing to the base on the adhesive for the vinyl floor.

Much more practical is Aquafloor quartz vinyl laminate on a hard WPC base, and even more perfect is Art Stone stone-polymer tile on an SPC tile.

A hard middle layer strengthens the structure of quartz vinyl, makes it possible to lay the flooring on minimally prepared substrates. In addition, the composite withstands temperature extremes from -30 to + 80 ° C: it is allowed to use the material in a bathhouse, sauna, outdoor terrace or conservatory without heating.

Features of Quartz Vinyl Tile

Vinyl is plastic, waterproof, easily mimics, that is, it takes the form of other materials. The polymer appears in the form of wood, stone, glass. However, the hardness of polyvinyl chloride is poor.

The material is easily scratched and worn. However, a solution was found here. Plates are covered with polyurethane film. It is transparent, performs a protective function. Another issue is the ecology of plastics. When heated, they vaporize poisons.

So, there are toxic substances in PVC and under ordinary conditions. The ductility of the material, for example, is achieved by the addition of phthalates. It is proven that they increase the risk of developing oncology, allergies, renal failure and liver diseases.

Contains polyvinyl chloride and formaldehydes. They rush into the air when the plastic is heated. Of the natural elements of PVC, cadmium and lead are poisoned. Burning just 1 kilo of polyvinyl chloride gives 50 grams of dioxin. In the laboratory, this is enough for the development of tumors in 50,000 rodents.

More than half of the PVC produced is used in construction. The houses already have PVC windows, decoration panels, plastic furniture, dishes. Therefore, it was decided to add quartz to the flooring. It is a mineral.

In nature, quartz is found in the form of jewelry amethyst, rock crystal, citrine, rauchtopaz and waste sand. In the last, particles of destroyed stones are poured. They are undermined by winds, streams of water.

Thrown sand formed only at first glance. It is technical quartz that goes into the production of building materials. One of them is glass. To get it, just re-melt the quartz.

The composition of the mineral is silicon dioxide. The element is famous for hardness. Quartz is also distinguished by it. According to the Mohs mineralogical scale, a gem is given 7 points. To the strongest diamond is not enough 3 units.

Due to silicon dioxide quartz vinyl floor tiles firmer, close to natural stone. In the masses, granite is considered to be the ideal of hardness. However, it yields a whole point to quartz.

With silicon dioxide, tiles become not only hard, but also approach artificial stone. Polyvinyl chloride in it is only a bonding, adhesive composition. Sand for slabs is not remelted. Rock particles need to be bonded with something, like crushed stone in concrete.

Quartz in the floor covering from 60 to 80 percent. The polymer accounts for no more than a quarter of the composition. The rest is additional additives, including dyes.

The materials in the quartz-vinyl coating are distributed in layers. The surface, as in the PVC plates, is “beaten off” by a polyurethane film. A decorative polyvinyl film, imitating the desired surface, shines through from under it. Then comes the quartz base. Its bottom is reinforced with glass fibers. Here is the 4th layer. The sandwich is finished with vinyl film.

Types of quartz vinyl coating

So, laid out the whole truth about quartz vinyl tile. Now classify it. The division of blocks is related to the type of connection. Allocate:

- Adhesive Quartz Vinyl Tile with locks. She easily lay down on old floors, excluding their dismantling. Blocks are attached to the glue, more precisely, 4 strips with it.

- Adhesive quartz vinyl tile without locks. This is attached to the floor, having a sticky bottom layer. Joints of panels are not smeared. Therefore, it requires an accurate and tight fit at the joints. Otherwise, annoying gaps remain. Considering this, for laying adhesive quartz vinyl tiles hire meticulous and professional finishers.

- Glue-mounted tile. She is devoid of a sticky back. Glue is bought separately and spread on the floor.

- Castle Quartz Vinyl Tile. Joins due to side spikes. They alternate with the protrusions of adjacent blocks, forming zigzag joints. Due to them, the castle quartz vinyl tile gives an especially strong coupling.

- Groove Quartz Vinyl Tile. Its fastenings are similar to laminate locks. There is a ledge on the side of one block, and a groove encircling it on the edge of the other.

If the adhesive blocks are able to cling to the floor with small irregularities, then the castle and groove plates require a perfectly flat base. Even millimeter tubercles and depressions loosen the locks in the coating.

When the “door” opens, a characteristic gap appears. Moisture penetrates into it, but for a stone-polymer composition this is not scary. More clutter is caused by mud clogging in the cracks.

Advantages and disadvantages of quartz vinyl tiles

Let's start by listing the benefits of quartz-quinol coating. He has more pros than cons. Therefore, in fact, the material moves the PVC plate on the market. So, the positive properties of quartz vinyl include:

-Incombustibility. Separately, PVC is highly flammable, but coupled with quartz sand, the polymer is losing ground.

- Moisture resistance. Quartz-vinyl blocks absorb moisture no more than ceramics. This distinguishes the coating from the laminate. It is not based on stone, but wood chips. Leaking in the cracks between the grooves of the “planks”, moisture leads to their swelling. Automatically increases the volume of the laminate. "Plates" begin to put pressure on the neighbors, and the coating is on the hillocks, needs to be replaced.

-Durability. The best laminate flooring is given a 10 year warranty. At quartz vinyl blocks it is like at a parquet. Manufacturers are responsible for the 35-year service of the plates.

- UV resistance. Many materials in the sun change color, usually fading. Quartzvinyl retains its original color even under direct rays. Moreover, you don’t have to worry about floors “covered” by walls, windows, curtains.

- Chemical inertness. The blocks themselves and adhesive for quartz vinyl tile. Materials do not react with most alkalis, acids, salts. The coating does not care household chemicals.

- Resistance to mechanical wear. Solid particles of quartz harden the blocks so much that the smallest scratches, chips, dents.

-Selection of design solutions. It is as wide as a plain PVC tile. The coating imitates not only wood, stone, plastic, but also the skin. You can get a double ceramic tile or porcelain.

Simple installation. If you level the rough screed of the floor, putting quartz vinyl tiles is not difficult. The task is within the power of anyone. A couple of online lessons are enough. We will move on to them in the next chapter. In the meantime, about the minuses of the heroine of the article:

- Quartz vinyl blocks are poorly separable from concrete. The ability to replace one, two blocks instead of the entire floor is an additional plus of the heroine of the article. However, quartz vinyl clings tightly to concrete. If the screed is not wooden, you have to put the lock plates. They cannot be replaced one at a time. As in the case of laminate flooring, parquet, you have to shovel the entire coating.

—Quartz Vinyl Slabs thin and plastic. Like thin wallpaper, they emphasize the unevenness of the floors, “bubble” on them. Therefore, a rough slab for quartz vinyl is prepared carefully and meticulously.

-Material is expensive. In many ways, winning over PVC slabs, quartz ones cost more. We'll talk about prices in the final article. In the meantime, the promised nuances of mounting quartz vinyl blocks.

Preparation of quartz vinyl tiles for installation

The preparation process before laying quartz vinyl includes not only leveling the screed, but also cleaning it from dust and dirt. Their absence is especially important when attaching plates to glue.

He grabs worse with dirty surfaces. Also, the screed must be cleaned of grease and primed. The primer will fill the micro-slots and provide maximum adhesion, that is, the penetration of glue into adjacent surfaces.

Preparing a wooden screed for quartz vinyl, cracks are searched for and putty in it. The primer will not fill them and glue literally seep through the "ground". By the way, the humidity of the base under the quartz tile should not exceed 5 percent.

Quartz vinyl tile laying technology

It has already been mentioned that the heroine of the article is attached to the rough screed in two ways. It remains to learn how to do this:

- The glue method involves applying a bonding agent to the floor. Tiles are attached to it after a maximum of 30 minutes, or better sooner. Each block is pressed to the base with a special roller. It can squeeze glue onto the surface of the plates. The mixture is removed with an alcoholized sponge. Glue, by the way, is used special. As a rule, these are dispersion and acrylic compositions. It is important to use the quartz vinyl tile recommended by the manufacturer. Furniture is placed on it at least a couple of days after installation. They wait the same amount before turning on the “warm floor” system.

- Castle method. We take to it the fastening with grooves. It is enough to bring the spike of one block to the bottom of the other and snap. Work begins with the layout of the room. It’s easier to find out how many plates you need, how to arrange them. It is important to leave a gap of a few millimeters on the walls. This is the space for pouring silicone sealant. However, the rule also applies to the laying of quartz vinyl by the adhesive method. Another general recommendation is +15 degrees and above in the workroom.

After laying the coating, you will have to take care of it. He is not troublesome. But, a few rules are there. The next chapter is dedicated to them.

Care for quartz vinyl tiles and the rules for its operation

The use of strong solvents such as turpentine and acetone is prohibited. The choice is to fall for a neutral detergent. Having treated them with floors, they are wiped dry. That's all quartz vinyl care.

Quartz vinyl tile laying roller

Among the detergents, by the way, there are specializing in vinyl surfaces. Such compounds must be purchased. However, the tile does not deteriorate from ordinary soapy water.

The price of quartz vinyl tiles and reviews about it

Quartz Vinyl Price set for 1 piece, or square meter. For the last one they ask, on average, 3,000 rubles. Most collections in Russia are imported from Finland or South Korea.

Price of South Korean Quartz Vinyl Tile 2, or even 2.5 times less. A square meter of coverage from Asia can be purchased for 1000 rubles. Such price tags are offered, for example, by the Decoria brand.

For a small price, a small abrasion class may be hidden. Quartzinyl is noted by him, like linoleum. A low indicator indicates the same resistance to external influences.

The high abrasion class allows the coating not only to serve 35 years, but also to remain attractive for all years. So, the low price is not always a cause for joy. It is necessary to evaluate the material according to its characteristics and labeling, and enticing cost.

The composition and structure of the material

Tile manufacturing technology involves the use of quartz sand (up to 80%), the rest belongs to polyvinyl chloride. A small part of the composition is also given to various impurities, plasticizers and pigments from natural components that give the product colors and textures.

The production process is the formation of a monolithic material by pressing together several layers, which include:

The production process is the formation of a monolithic material by pressing together several layers, which include:

• polyvinyl chloride (it is the basis that provides good adhesion to the floor),

• fiberglass (as reinforcement),

• a base made of quartz and vinyl,

• a decorative layer (forms the invoice),

• polyurethane (protection against slipping and mechanical stress).

The technology was developed by the Japanese, and the progenitors of production were Koreans. High operational and technical characteristics were noted by manufacturers Art Tile, Upofloor and Fine Floor, which put safety and quality in the first place. Therefore, it is safe to advise their products for the arrangement of floors in children's and playrooms.

Pros and Cons of Quartz Vinyl Tile

Those consumers who decided to take advantage of the novelty in flooring, managed to appreciate the advantages of tiles. Among the advantages claimed by the manufacturer:

• coating strength and resistance to mechanical stress,

• the ability to repair damaged areas,

• antistatic allows you to use the product with a warm floor system,

• high resistance to abrasives and detergents with chemical compounds,

• improves sound insulation in the room,

• the coating is not susceptible to microbiological processes,

• the material is moisture resistant, which makes it possible to use it in rooms with a high level of humidity,

• long operational period (15 years),

• long operational period (15 years),

• the absence of a sliding effect reduces the risk of injury,

• dies when burning, is not subject to fire,

• easy to process and style,

• the floor is easy to care for, it is enough to do wet cleaning,

• does not emit toxic substances during operation, which means safety for human health,

• tactile contacts when walking are comfortable and soft,

• From a wide range of colors and textures, you can choose the most suitable option for the interior.

One of the main advantages is the absence of phenols and melamine in the composition, which are harmful to both households and their pets.

One of the main advantages is the absence of phenols and melamine in the composition, which are harmful to both households and their pets.

In fairness, you need to consider the disadvantages of flooring. Among the minuses of quartz vinyl tiles:

• dents may remain from heavy furniture on the surface of quartz vinyl tiles,

• before laying, you need to level the base so that the surface is perfectly smooth,

• according to reviews, some manufacturers produce low-quality products, when laid which there is a discrepancy in the geometry of the picture, poor resistance to ultraviolet.

Types of Quartz Vinyl Tiles

Quartz vinyl tiles are classified according to various criteria.

- in the form of dies (like a laminate),

- in the form of a square.

• According to the installation method:

- with fixing with adhesive composition,

- connection using the lock part,

- products on a self-adhesive basis.

• By class of abrasion:

- 31-33 class (for rooms with low traffic),

- 34 class (for living rooms and halls, office premises).

The product is available in a wide range of color schemes and textures.